Environment-friendly leather bag with high smoothness and manufacturing method of environment-friendly leather bag

A manufacturing method and smoothness technology, applied in chemical instruments and methods, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve poor wet rub resistance, Coating peeling on the coating surface, leather cracking and discoloration, etc., to achieve the effect of ensuring the brightness of the dyeing, preventing sediment, and a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

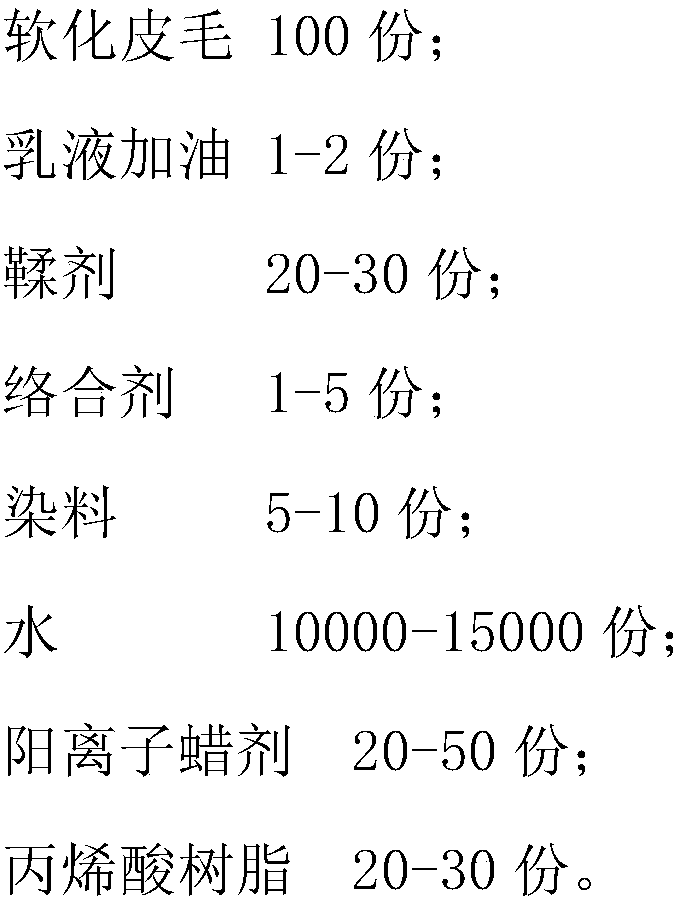

Method used

Image

Examples

Embodiment 1

[0031] Embodiment one: the present invention proposes a kind of manufacturing method of the high smoothness environmental-friendly leather bag, it is characterized in that: comprise the following steps:

[0032] 1. At room temperature, add softened fur, emulsion oil, and tanning agent in sequence for mixing, and the mixing ratio is 100:1:10 to obtain mixed fur;

[0033] 2. Stir the above-mentioned mixed fur, and stir for 2 hours to obtain the emulsion fur;

[0034] 3. Add tanning agent to the emulsion fur, the mass percentage of softening fur and tanning agent is 100:20;

[0035] 4. Step 3 is dried to obtain the environment-friendly leather, and every 100 parts by mass of the environment-friendly leather is added with 20 cationic waxes to stir, and the stirring time is to stir the environment-friendly leather and cationic wax evenly and then dry them;

[0036] Five: Sew two identical pieces of leather dried in Step 5 on three sides, and sew a zipper on the other side.

[003...

Embodiment 2

[0038] Embodiment two: the present invention proposes a kind of manufacturing method of the high smoothness environmental-friendly leather bag, it is characterized in that: comprise the following steps:

[0039] 1. At room temperature, add softened fur, emulsion oil, and tanning agent in sequence for mixing, and the mixing ratio is 100:2:20 to obtain mixed fur;

[0040] 2. Stir the above-mentioned mixed fur, and stir for 3 hours to obtain the emulsion fur;

[0041] 3. Add tanning agent to the emulsion fur, the mass percentage of softening fur and tanning agent is 100:10;

[0042] 4. Step 3 is dried to obtain the environment-friendly leather, and every 100 parts by mass of the environment-friendly leather is added with 50% cationic wax for stirring. The time for stirring is to stir the environment-friendly leather and cationic wax evenly and then dry it;

[0043] 5. Sew two identical pieces of leather dried in step 5 on three sides, and sew a zipper on the other side.

[0044...

Embodiment 3

[0045] Embodiment three: the present invention proposes a kind of manufacturing method of the high smoothness environmental-friendly leather bag, it is characterized in that: comprise the following steps:

[0046]1. At normal temperature, add softened fur, emulsion oil, and tanning agent in sequence for mixing, and the mixing ratio is 100:1:15 to obtain mixed fur;

[0047] 2. Stir the above-mentioned mixed fur, and stir for 2 hours to obtain the emulsion fur;

[0048] 3. Add tanning agent to the emulsion fur, the mass percentage of softening fur and tanning agent is 100:1;

[0049] 4. Step 3 is dried to obtain the environment-friendly leather, and every 100 parts by mass of the environment-friendly leather is added with 20 cationic waxes to stir, and the stirring time is to stir the environment-friendly leather and cationic wax evenly and then dry them;

[0050] 5. Sew two identical pieces of leather dried in step 5 on three sides, and sew a zipper on the other side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com