Friction material composition and friction material

A technology of friction materials and compositions, applied in the direction of friction linings, chemical instruments and methods, gear transmission mechanisms, etc., can solve the problems of increased friction coefficient, prone to whistling, inability to provide copper ductile and ductile lubrication functions, etc. problem, to achieve stable friction coefficient and small load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

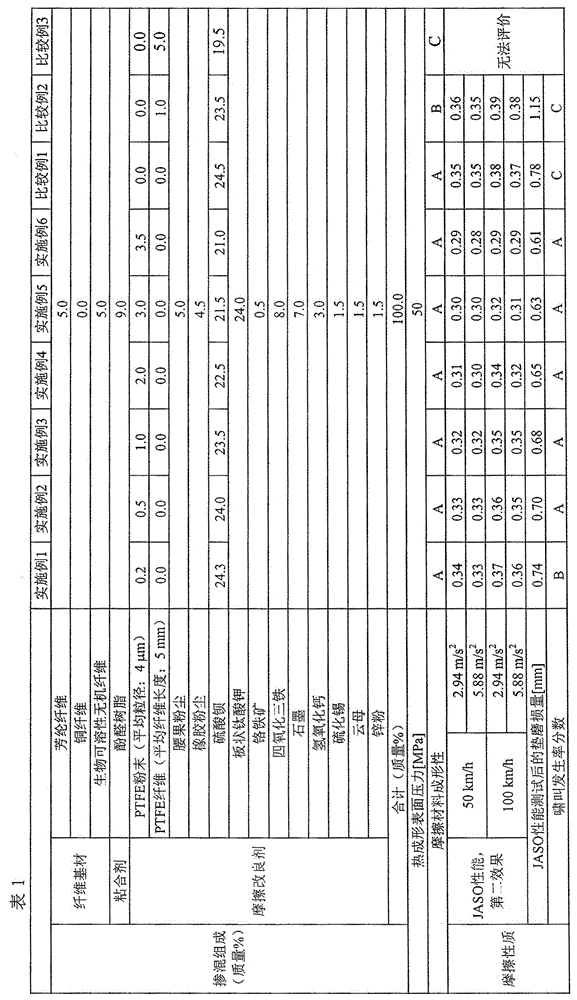

Embodiment 1~6 and comparative example 1~3

[0049]

[0050] The blended materials shown in Table 1 were placed together in a mixing mixer, followed by mixing at room temperature for 2 minutes to 10 minutes, thereby obtaining a friction material composition. The obtained friction material compositions are processed through the steps of preforming (1), thermoforming (2), heating and firing (3), so as to prepare friction materials.

[0051] (1) Preformed

[0052] The above-mentioned friction material composition was placed in a mold of a preforming press, followed by forming at room temperature at 20 MPa for 5 seconds, thereby preparing a preformed product (sample size: 45×80 mm).

[0053] (2) Thermoforming

[0054] The preformed product was placed in a thermoforming mold, and a metal plate (press plate: P / P) coated with an adhesive in advance was laminated thereon, followed by thermocompression forming at 150° C. and 50 MPa for 5 minutes.

[0055] (3) heating and firing

[0056] This thermoformed product was heat-tre...

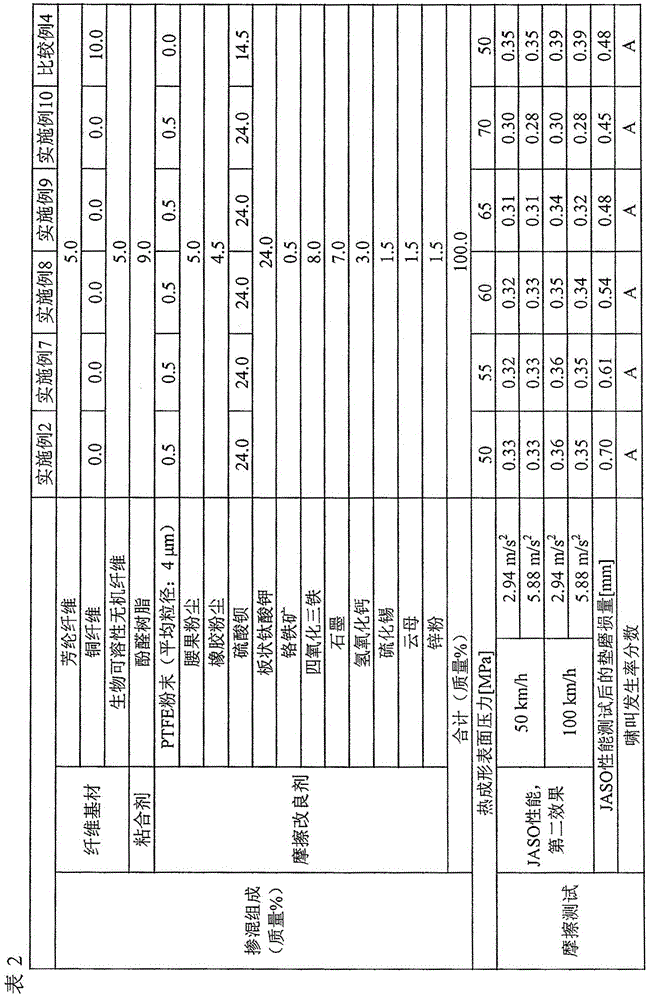

Embodiment 7~10 and comparative example 4

[0079]

[0080] Friction materials were manufactured using the blended materials shown in Table 2 in the same manner as in Test Example 1, but the thermoforming surface pressure in thermoforming (2) was changed to be in the range of 50 MPa to 70 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com