Particle reinforced aluminum matrix composite for automobile piston and preparation method of particle reinforced aluminum matrix composite

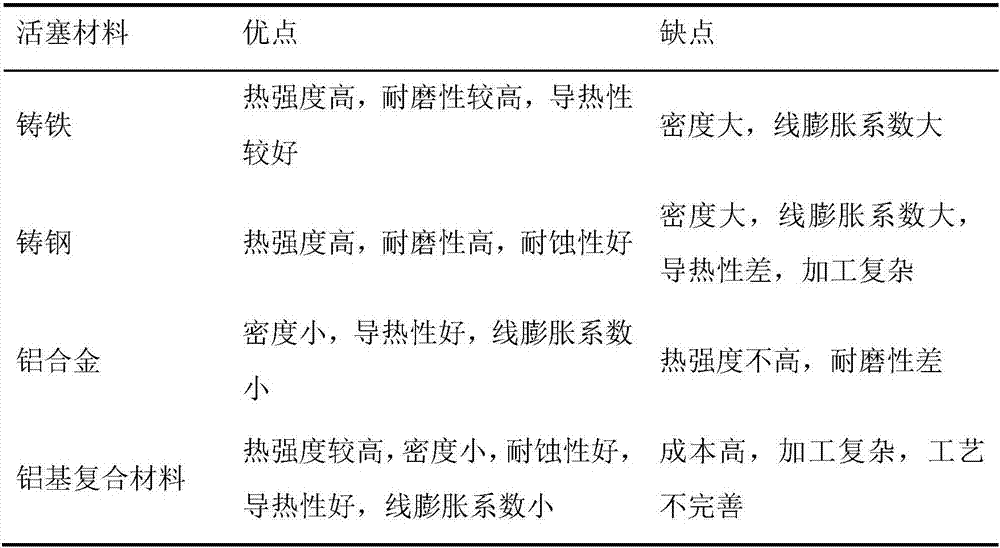

An aluminum-based composite material and particle-reinforced aluminum technology, which is applied in the field of particle-reinforced aluminum-based composite materials for automobile pistons and its preparation, can solve the problems of poor heat resistance and high-temperature strength, and improve high-temperature mechanical properties and high-temperature wear resistance effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

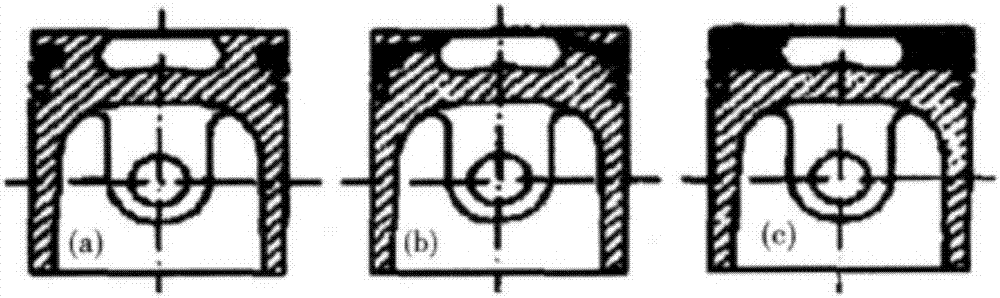

Image

Examples

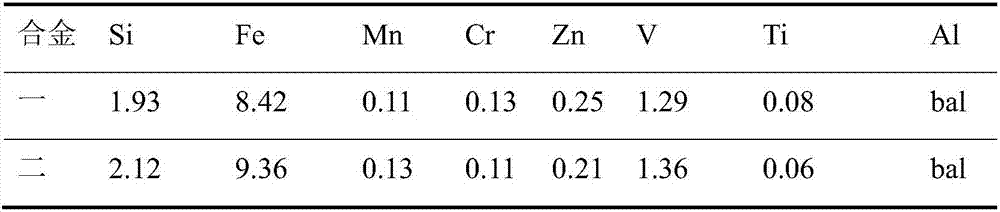

Embodiment 1

[0041] The alloy is formulated according to the weight fraction of the aluminum alloy matrix powder of the present invention, and Fe and V in the matrix alloy are added in the form of Al-40Fe and Al-40Fe-10V master alloys. Firstly, A1-40Fe and A1-40Fe-10V master alloys are melted at about 1600°C in an intermediate frequency induction furnace, and then an appropriate amount of pure aluminum and pure silicon is added to melt Al-8.5Fe-1.3V-1.7Si mother alloys at 1020°C Alloy, then atomize the powder with nitrogen gas, its chemical composition is as Alloy 1 in Table 1; then mix evenly with 10% SiC particles and 2% graphite according to the volume fraction, after mixing, put it into 5mm thick 3003 aluminum alloy The tube is compacted and vacuum degassed to make an extruded ingot with a size of Ф152×450mm, and the relative density is about 78%.

[0042] The heating temperature is 470-480°C, the heating rate is 50°C / hour, and the holding time is 4 hours; the mold temperature is 420-4...

Embodiment 2

[0044] The alloy is formulated according to the weight fraction of the aluminum alloy matrix powder of the present invention, and Fe and V in the matrix alloy are added in the form of Al-40Fe and Al-40Fe-10V master alloys. Firstly, A1-40Fe and A1-40Fe-10V master alloys are melted at about 1600°C in an intermediate frequency induction furnace, and then an appropriate amount of pure aluminum and pure silicon is added to melt Al-8.5Fe-1.3V-1.7Si mother alloys at 1020°C alloy, and then atomize the powder with nitrogen gas, and its chemical composition is as alloy 1 in Table 1; then mix evenly with 15% SiC particles and 1% graphite according to the volume fraction, and then put it into 5mm thick 3003 aluminum alloy after mixing The tube is compacted and vacuum degassed to make an extruded ingot with a size of Ф175×550mm, and the relative density is about 72%.

[0045] The heating temperature is 490-500°C, the heating rate is 40°C / hour, and the holding time is 5 hours; the mold temp...

Embodiment 3

[0048] The alloy is formulated according to the weight fraction of the aluminum alloy matrix powder of the present invention, and Fe and V in the matrix alloy are added in the form of Al-40Fe and Al-40Fe-10V master alloys. Firstly, A1-40Fe and A1-40Fe-10V master alloys are melted at about 1600°C in an intermediate frequency induction furnace, and then an appropriate amount of pure aluminum and pure silicon is added to melt Al-8.5Fe-1.3V-1.7Si mother alloys at 1020°C alloy, and then atomize the powder with nitrogen gas, and its chemical composition is as alloy 1 in Table 1; then mix evenly with 20% SiC particles and 1% graphite according to the volume fraction, and then put it into 5mm thick 3003 aluminum alloy after mixing The tube is compacted and vacuum degassed to make an extruded ingot with a size of Ф175×550mm, and the relative density is about 71%.

[0049] The heating temperature is 490-500°C, the heating rate is 40°C / hour, and the holding time is 5 hours; the mold temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com