Turbofan flow sensor

A flow sensor, turbofan technology, applied in the direction of volume/mass flow generated by mechanical effects, dynamic effects by detecting fluid flow, etc., can solve problems such as limited equipment or site pipeline space, restricted flow accurate measurement, etc., to ensure Effects of repeatability and consistency, stable coefficient of friction and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

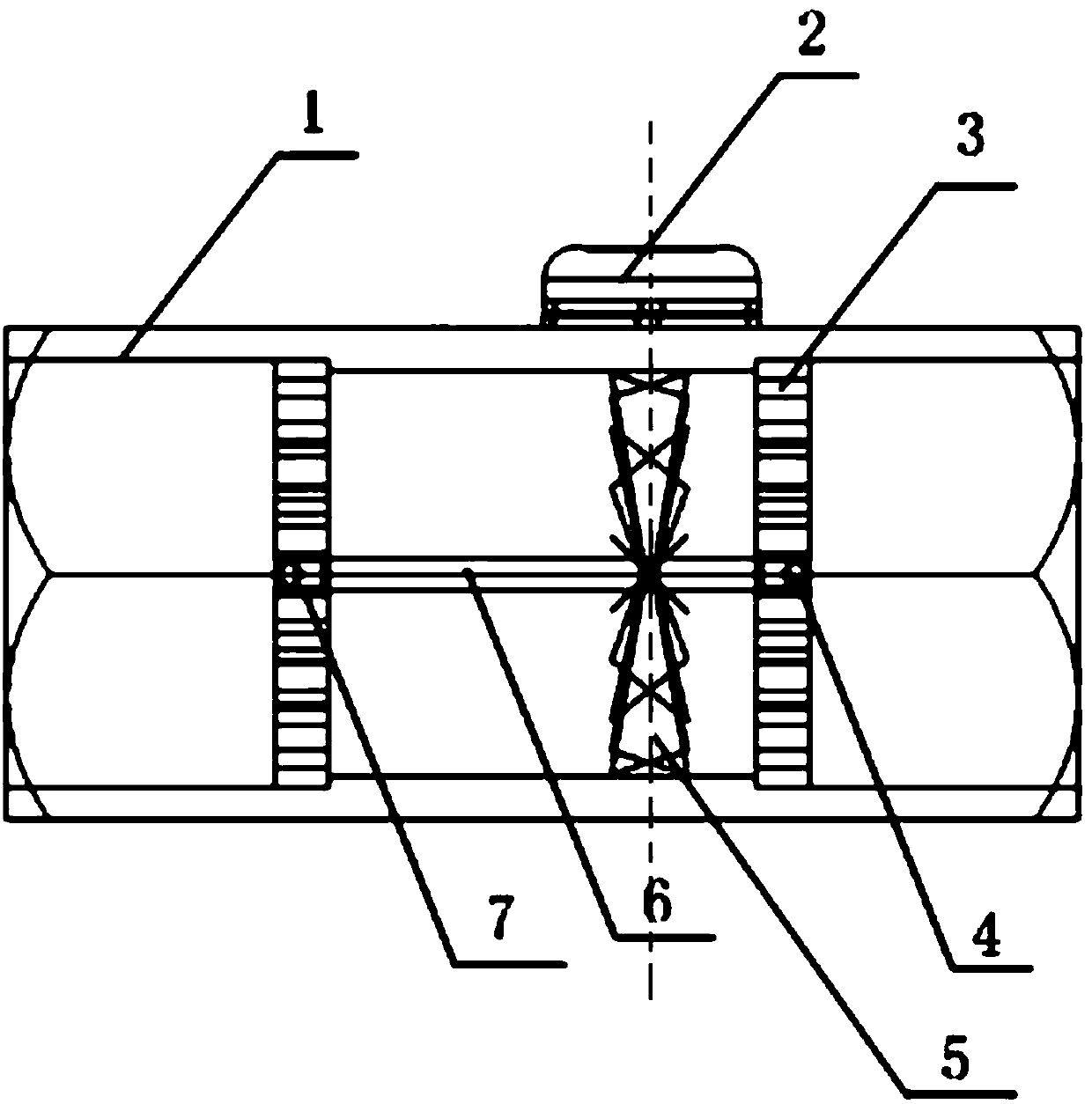

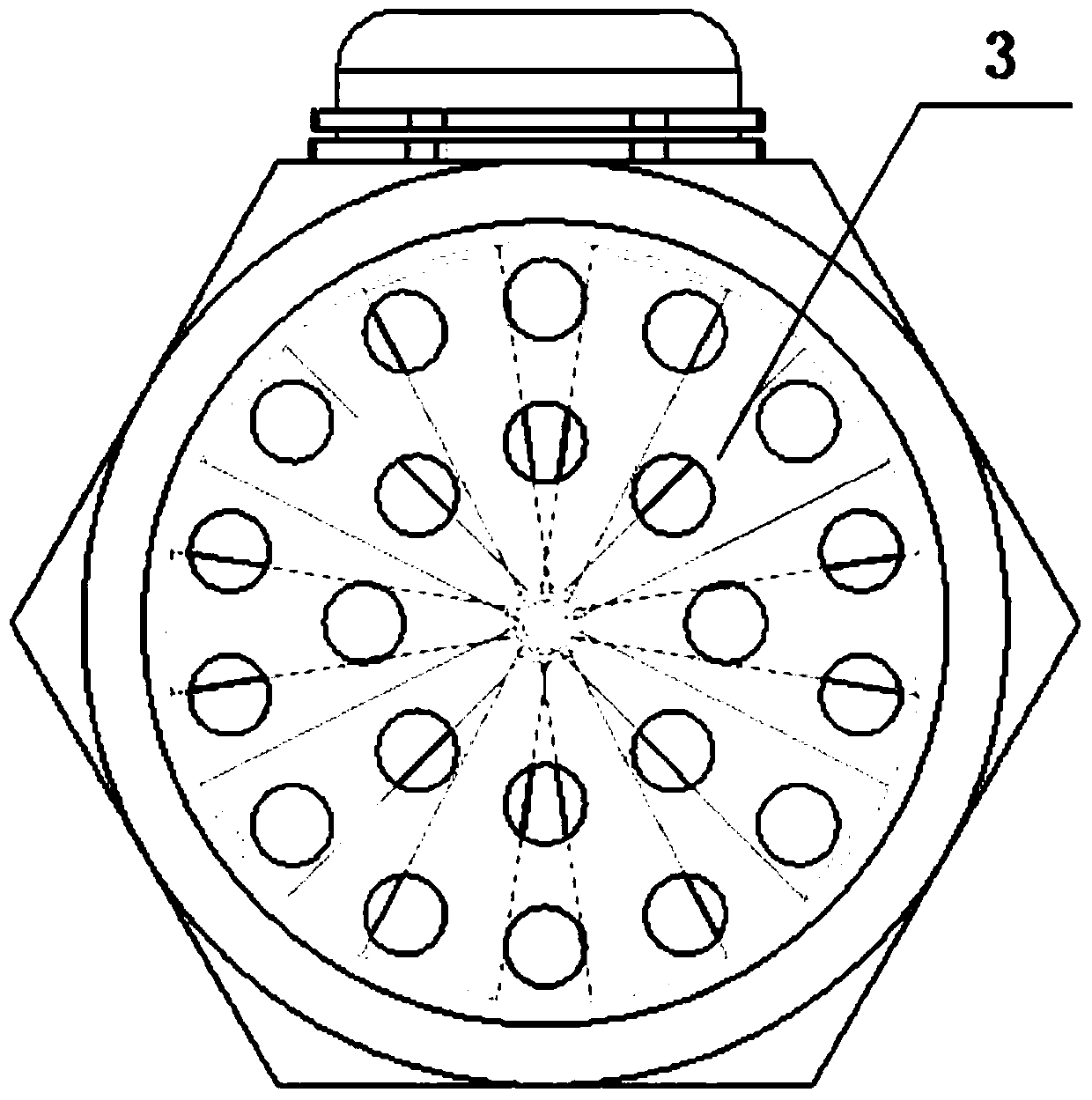

[0015] Such as figure 1 As shown, the present invention provides a turbofan flow sensor, including: a housing 1, a Hall switch 2, a turbofan frame 3, a steel ball 4, a turbofan 5, a shaft 6 and a bearing 7, and the housing 1 is The shape of a cylinder with two ends open, one end is used as a liquid inlet, and the other end is used as a liquid outlet, and the casing 1 is made of metal material, the vortex fan 5 is made of magnetic material, and the vortex fan frame 3 (as a rectifying plate) There are a plurality of through holes distributed on it, the Hall switch 2 is installed on the housing 1, and the Hall switch 2 is located directly above the turbofan 5, the turbofan frame 3, steel ball 4, turbofan 5. The shaft 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com