High-ratio methanol fuel composite additive for vehicles

A compound additive and high-proportion technology, applied in fuel additives, fuel, liquid carbon-containing fuel, etc., can solve the problems of reduced fuel pump life, increased fuel consumption, and wear, and achieve the effect of improving poor lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Get 60 Kg of fatty acid methyl ester, 20 Kg of amyl nitrate, 5 Kg of glycerol, 10 Kg of benzotriazole, and 5 Kg of ethanol.

[0071] In a constant temperature water bath at 60°C, use 5 Kg of ethanol as a solvent, add 5 Kg of glycerin and 10Kg of benzotriazole to the above solvent in sequence and stir until completely dissolved, then add 20 Kg of amyl nitrate to the dissolved solution and stir to make uniform mixing, and finally mix the mixed solution with 60Kg fatty acid methyl ester and reconcile evenly to obtain 100 Kg of the high-proportion vehicle methanol fuel composite additive of the present invention.

[0072] Add 3Kg of the above-mentioned additives into 97 Kg of M100 methanol fuel, and stir evenly to obtain M100 vehicle methanol fuel.

Embodiment 2

[0074] Get fatty acid isopropyl ester 50Kg, isooctyl nitrate 30 Kg, glycerol 7Kg, benzotriazole 5 Kg, propanol 8Kg.

[0075] In a constant temperature water bath at 60°C, use 8Kg of propanol as a solvent, add 7 Kg of glycerol and 5Kg of benzotriazole into the above solvent in sequence and stir until completely dissolved, then add 30 Kg of isooctyl nitrate into the dissolved solution Esters are stirred and evenly mixed, and finally the mixed solution is mixed with 50Kg fatty acid isopropyl ester and blended uniformly to obtain 100 Kg of the high-ratio vehicle methanol fuel composite additive of the present invention.

[0076] Take 1 Kg of the above-mentioned additive and add it into 99 Kg of M85 methanol fuel, and stir evenly to obtain M85 vehicle methanol gasoline fuel.

Embodiment 3

[0078] Get fatty acid ethyl ester 70Kg, cyclohexyl nitrate 10Kg, glycerol 10Kg, benzotriazole 5Kg, isobutanol 5Kg.

[0079] In a constant temperature water bath at 60°C, use 5Kg of isobutanol as a solvent, add 10Kg of glycerol and 5Kg of benzotriazole into the above solvent and stir until completely dissolved, and add 10 Kg of cyclohexyl nitrate into the dissolved solution and stir to make uniform mixing, and finally mix the mixed solution with 70Kg fatty acid ethyl ester and blend evenly to obtain 100 Kg of the high-proportion vehicle methanol fuel composite additive of the present invention.

[0080] Get above-mentioned additive 0.1Kg and add in 99.9Kg M15 methanol fuel, stir evenly and promptly obtain 100Kg M15 methanol gasoline fuel for vehicles.

PUM

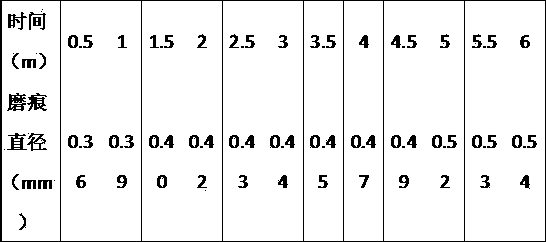

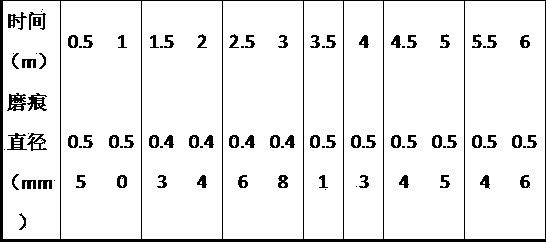

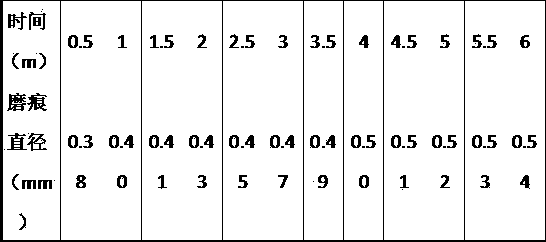

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com