Method for preparing wear-resistant material from tungsten tailings

A technology of wear-resistant materials and tungsten tailings, applied in the direction of coating, etc., can solve the problems of limited number of applications, low-end products, complex processes, etc., and achieve the effects of simple process, improved wear resistance, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing wear-resistant materials from tungsten tailings, the operation steps comprising: drying the tungsten tailings to a moisture content of less than 5%, sieving with a 200-mesh standard sieve, performing combined gravity-magnetic separation on the products under the sieve, and selecting The final product is jet milled, and the ultrafine tungsten tailings powder is classified, and the wear-resistant material is obtained by taking the product with a mesh size of 600 or more. The yield and garnet content of each intermediate product and wear-resistant material are shown in Table 1.

[0020] Table 1 Intermediate product and wear-resistant material yield and garnet content

[0021] product

Embodiment 2

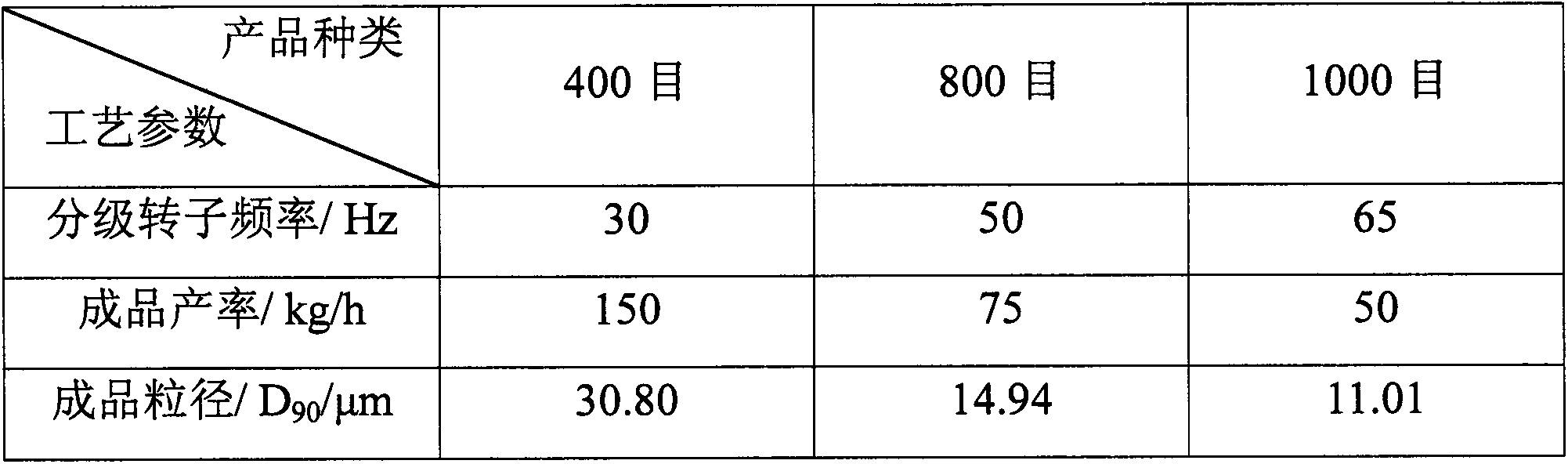

[0023] An ultra-fine processing method for preparing wear-resistant materials from tungsten tailings. The operation steps include: drying the tungsten tailings to a moisture content below 5%, and after screening, use a jet mill to achieve ultra-fine processing of the tungsten tailings through high-speed airflow. Fine processing, the pulverized tungsten tailings powder is classified by air to obtain tungsten tailings fine powder that meets the particle size requirements.

[0024] Table 2 Jet Milling Process Parameters

[0025]

Embodiment 3

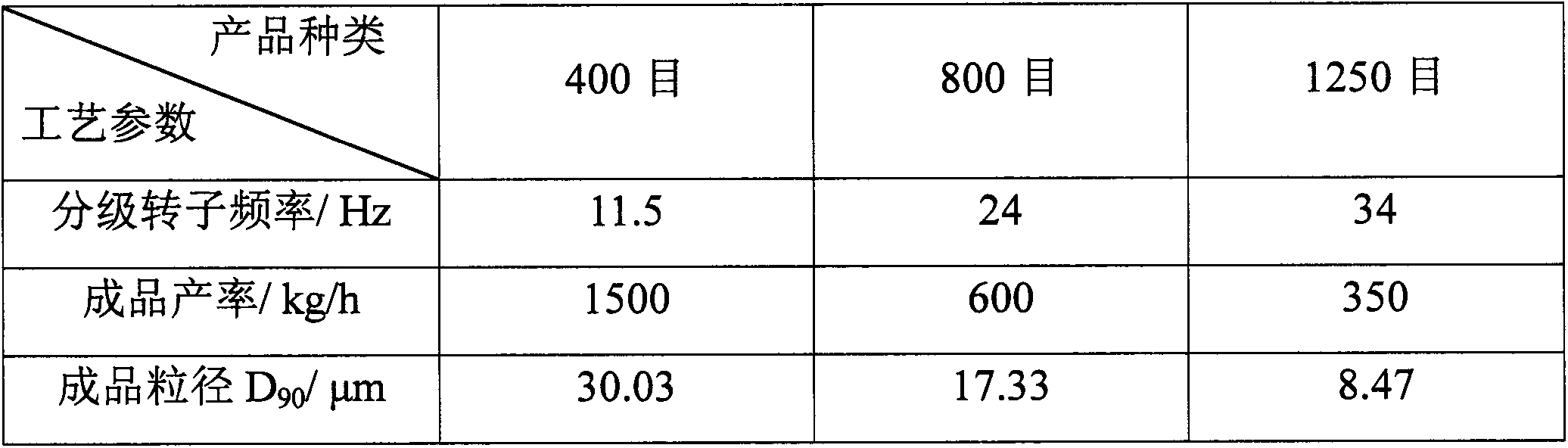

[0027] An ultra-fine processing method for preparing wear-resistant materials from tungsten tailings. The operation steps include: drying the tungsten tailings to a moisture content below 5%, sieving, classifying by ball mills, and realizing ultra-fine grinding of the tungsten tailings by means of closed-circuit grinding. Fine processing to obtain tungsten tailings fine powder that meets the particle size requirements.

[0028] Table 3 Ball mill classification process parameters

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com