Novel degradable plastic bag and preparation method thereof

A plastic bag and a new type of technology are applied in the field of new degradable plastic bags and their preparation, which can solve the problems of poor environmental resistance, human body influence, inability to be used and carried repeatedly, etc., and achieve the effects of improving comprehensive performance and strengthening extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

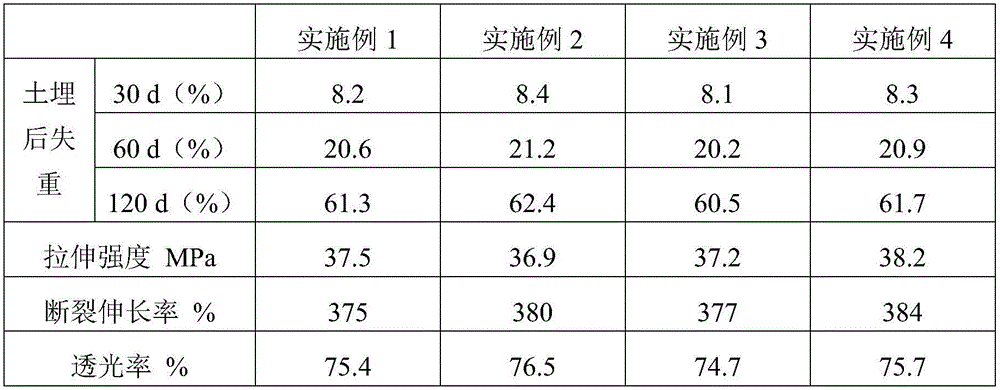

Examples

Embodiment 1

[0037]The invention provides a novel degradable plastic bag, which comprises the following raw materials in parts by weight: 70 parts of tapioca starch, 30 parts of polyvinyl alcohol, 20 parts of sisal fiber, 10 parts of ramie fiber, 15 parts of banana fiber, and 30 parts of clouding agent 0.5 part of 4% aqueous solution of calcium lactate, 0.1 part of cactus, 0.4 part of rosemary, 0.2 part of ginkgo, 0.2 part of cardamom and 0.3 part of bamboo leaf;

[0038] Wherein, the clouding agent is a commercially available oil-in-water clouding agent.

[0039] Biodegradable tapioca starch materials and sisal fibers, ramie fibers, and banana fibers are used to prepare degradable plastic bags, and comprehensive utilization of the wear resistance and corrosion resistance of sisal fibers, the elasticity of ramie fibers, and the light weight and durability of banana fibers Gloss, adding polyvinyl alcohol, can effectively increase the load-bearing pressure of plastic bags, so that it can be ...

Embodiment 2

[0055] The invention provides a novel degradable plastic bag, which comprises the following raw materials in parts by weight: 60 parts of tapioca starch, 40 parts of polyvinyl alcohol, 15 parts of sisal fiber, 15 parts of ramie fiber, 7 parts of banana fiber, and 40 parts of clouding agent 0.2 part of 4% aqueous solution of calcium lactate, 0.2 part of cactus, 0.2 part of rosemary, 0.3 part of ginkgo, 0.1 part of cardamom and 0.4 part of bamboo leaf;

[0056] Wherein, the clouding agent is a commercially available oil-in-water clouding agent.

[0057] Biodegradable tapioca starch materials and sisal fibers, ramie fibers, and banana fibers are used to prepare degradable plastic bags, and comprehensive utilization of the wear resistance and corrosion resistance of sisal fibers, the elasticity of ramie fibers, and the light weight and durability of banana fibers Gloss, adding polyvinyl alcohol, can effectively increase the load-bearing pressure of plastic bags, so that it can be ...

Embodiment 3

[0073] The invention provides a novel degradable plastic bag, which comprises the following raw materials in parts by weight: 70 parts of tapioca starch, 30 parts of polyvinyl alcohol, 20 parts of sisal fiber, 10 parts of ramie fiber, 15 parts of banana fiber, and 30 parts of clouding agent 0.2 part of 2% calcium phosphate aqueous solution, 0.2 part of cactus, 0.2 part of rosemary, 0.3 part of ginkgo, 0.1 part of cardamom and 0.4 part of bamboo leaf;

[0074] Wherein, the clouding agent is a commercially available oil-in-water clouding agent.

[0075] Biodegradable tapioca starch materials and sisal fibers, ramie fibers, and banana fibers are used to prepare degradable plastic bags, and comprehensive utilization of the wear resistance and corrosion resistance of sisal fibers, the elasticity of ramie fibers, and the light weight and durability of banana fibers Gloss, adding polyvinyl alcohol, can effectively increase the load-bearing pressure of plastic bags, so that it can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com