Dual-roller type banana stalk crushing and returning machine

A banana straw and straw crushing technology, which is applied to harvesters, agricultural machinery and tools, agriculture, etc., can solve the problems of waste of resources, time-consuming, environmental pollution, etc., to improve crushing efficiency, save use costs, facilitate maintenance and The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

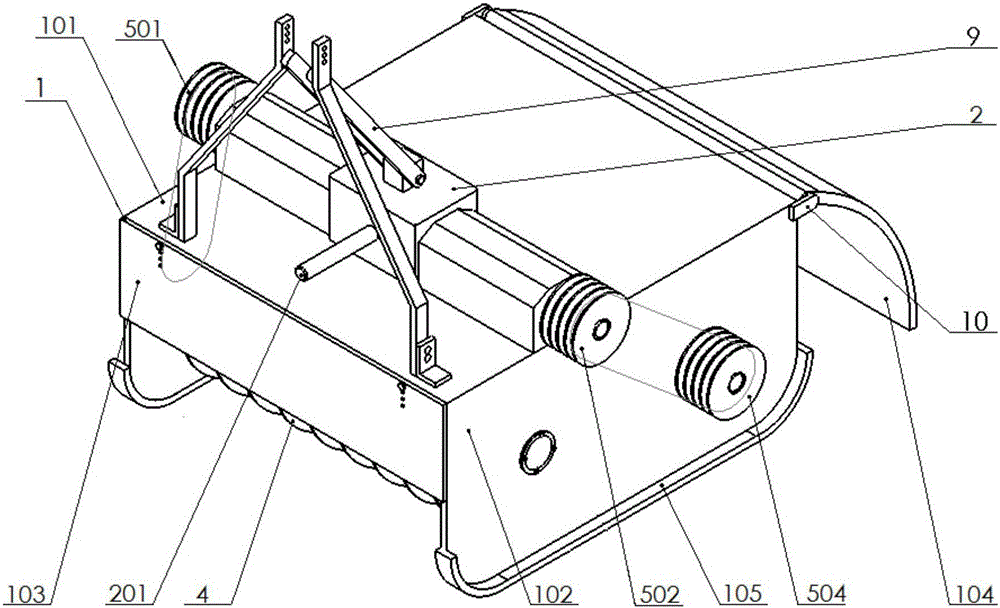

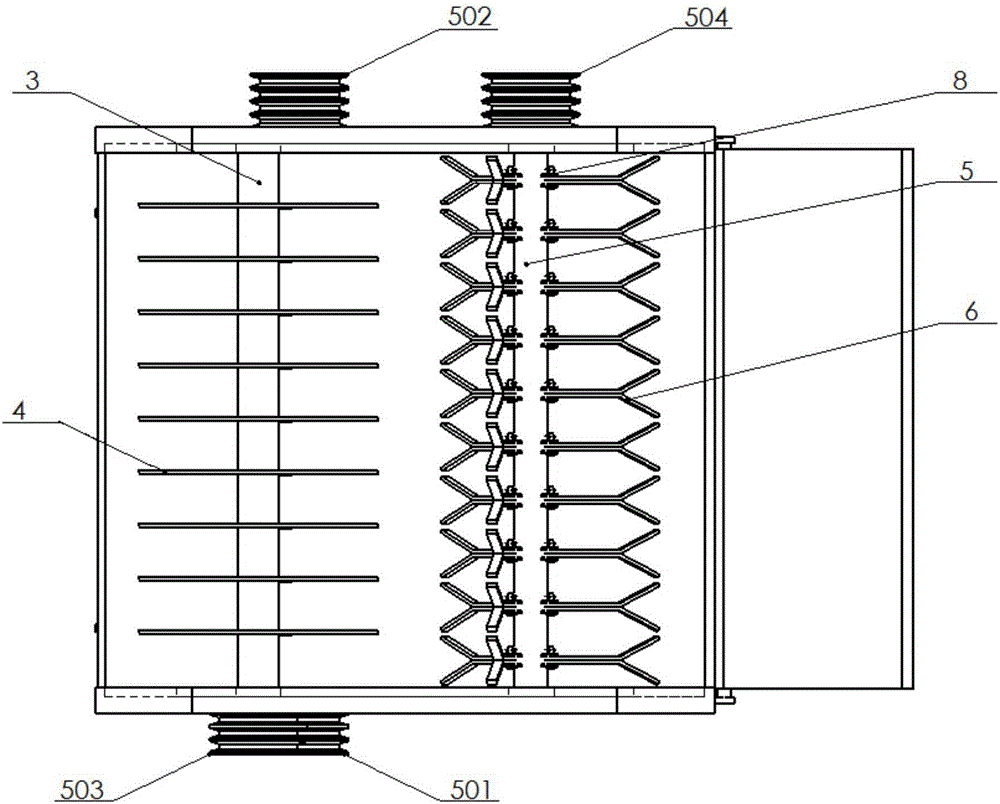

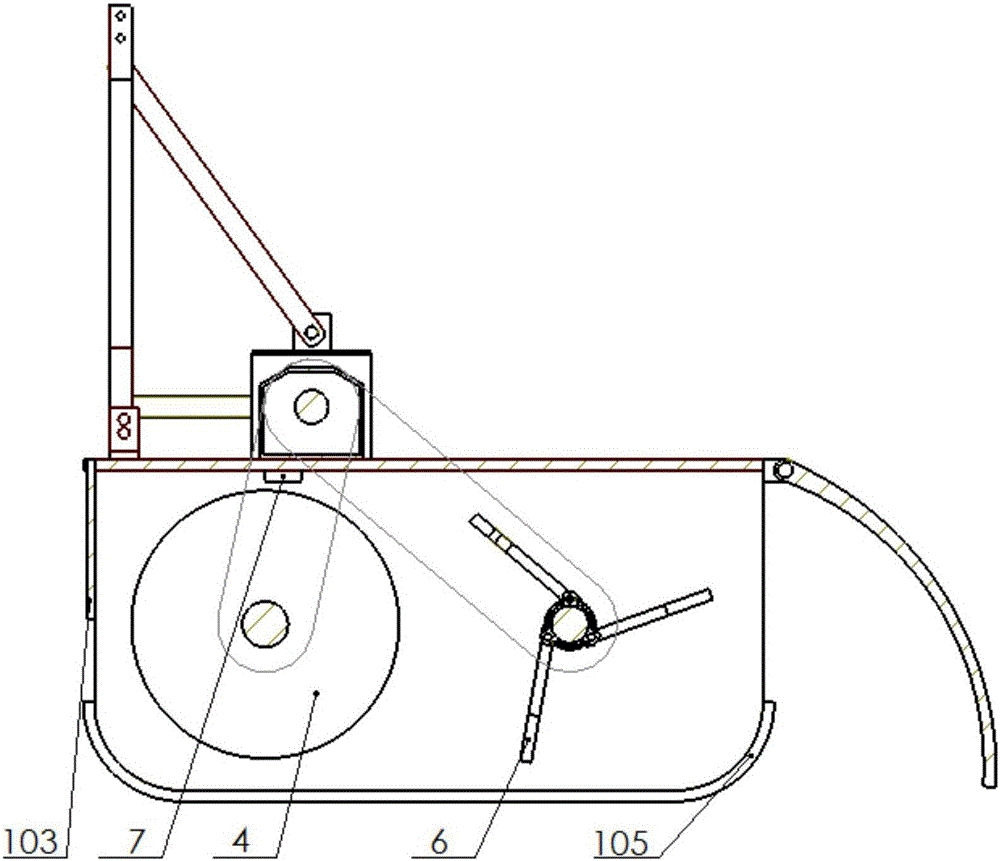

[0029] Such as Figure 1-Figure 4 The shown two-roller banana straw crushing and returning machine includes a frame 1, a three-point suspension device 9, a transmission device and a straw crushing and returning device.

[0030] Described frame 1, the left and right sides of its top plate 101 are respectively connected with the upper edge of left and right side plates 102, the front side is connected with the upper edge of rectangular baffle plate 103, and the rear side is connected with the cover plate 104 through lifting lug 10. connection on the upper edge. Below the rectangular baffle 103 is a feeding inlet, and the rectangular baffle 103 is provided with two vertical rows of mounting holes on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com