Method for preparing anti-flaming banana fiber epoxy resin composite material

A technology of banana fiber and epoxy resin, which is applied in the field of preparation of flame-retardant banana fiber epoxy resin composite materials, can solve problems such as black smoke, high temperature, and high heat, and achieve low product cost, light weight, and machinability good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

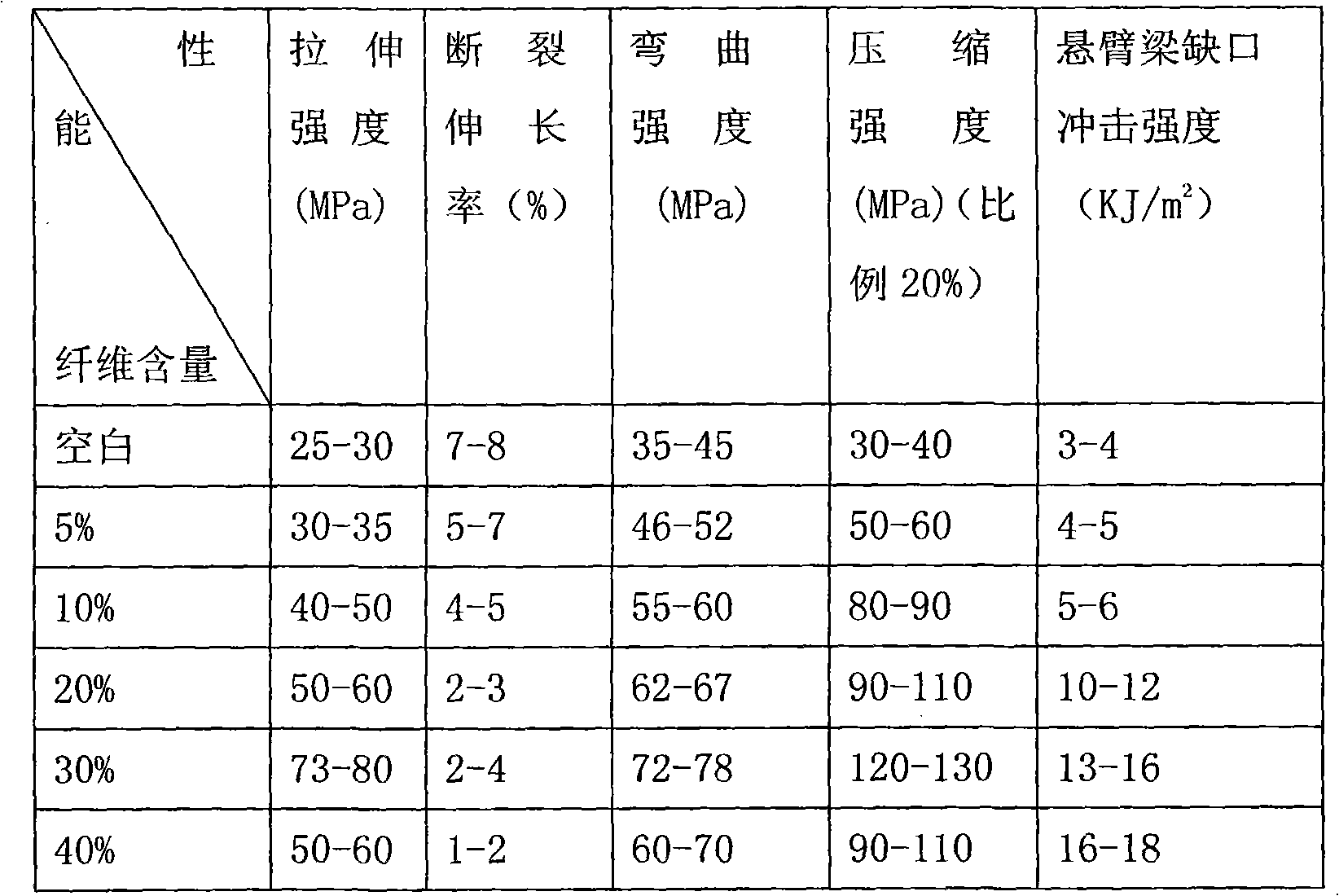

Embodiment 1

[0042]Cut the banana fiber treated with coupling agent A-174 to a length of 5mm, and put it in a vacuum drying oven at 70°C for 1 hour; the test was divided into six groups, each group containing 100g of epoxy resin E-44 , low molecular weight polyamide resin 650 (100g), acetone 12.5g, dibutyl phthalate 5g, curing accelerator 1,2-dimethylimidazole 0.5g, mix uniformly; Divided into six groups, the banana fiber content of each group is respectively 0% of the mass sum of the banana fiber, epoxy resin, low molecular weight polyamide resin, acetone, dibutyl phthalate, and 1,2-dimethylimidazole . The banana fiber is mixed evenly with an electric strong mixer, and each group of mixtures is injected into the mold separately, and hot-pressed and solidified on a flat vulcanizing machine. The hot-pressing temperature is 120°C, the hot-pressing time is 5min, and the pressure is 10MPa. . Post-treatment was carried out by heating at a constant temperature of 70° C. in a drying oven for 5 ...

Embodiment 2

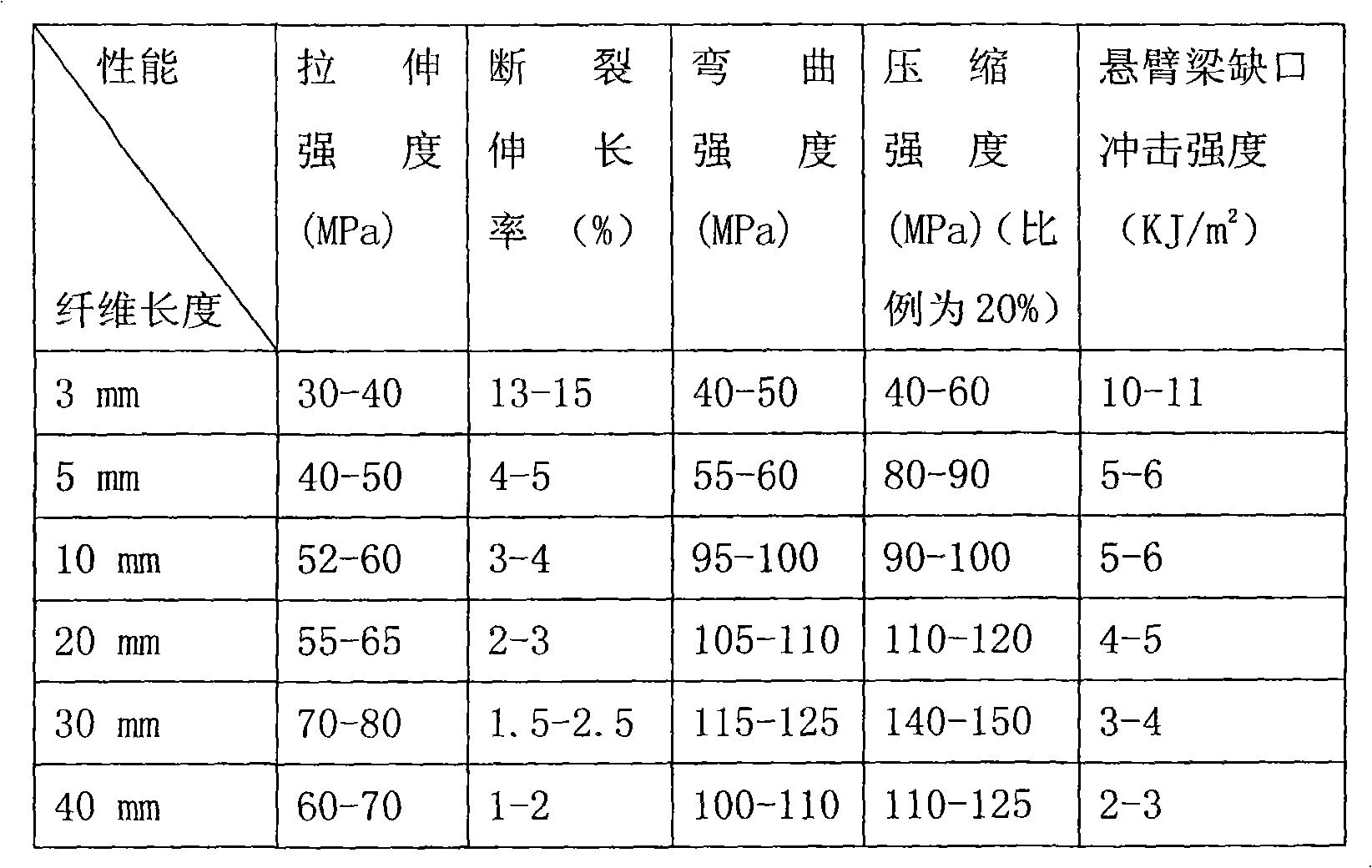

[0047] The method is the same as Example 1, except that the lengths of the added fibers are 3mm, 5mm, 10mm, 20mm, 30mm, 40mm, etc., and the content is 10%, that is, the quality of the added fibers is 24.18g, and they are hot-pressed and solidified on a flat vulcanizing machine. , the hot-pressing temperature is 130°C, the hot-pressing time is 3min, the pressure is 10MPa, and then the sheet is cooled. Post-treatment was carried out by heating at a constant temperature of 70° C. in a drying oven for 5 hours. Each sample was tested 5 times, and the specific mechanical properties are shown in Table 2.

[0048] Table 2 Mechanical properties of banana fiber epoxy resin composites with different fiber lengths (10% content)

[0049]

[0050] It can be seen from Table 2 that the mechanical properties of the composite material are the best when the length of the banana fiber is about 30mm.

Embodiment 3

[0052] Weigh epoxy resin E-44 (100g), low molecular weight polyamide resin 650 (100g), TBA is 30g, Sb 2 o 3 10g, acetone 11g, dibutyl phthalate 6.5g, accelerator 1,2-dimethylimidazole 0.8g, add 30% (110.43g) of the fiber after coupling and flame retardant treatment to the total mass . It is formed by hot-pressing and solidifying on a flat vulcanizing machine. The hot-pressing temperature is 120° C., the hot-pressing time is 6 minutes, and the pressure is 10 MPa, and then the sheet is cooled. Post-treatment was carried out by heating at a constant temperature of 70° C. in a drying oven for 5 hours. All the other steps are the same as in Example 1. The sample was tested 5 times according to the standard, and the specific mechanical properties and flame retardant properties are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com