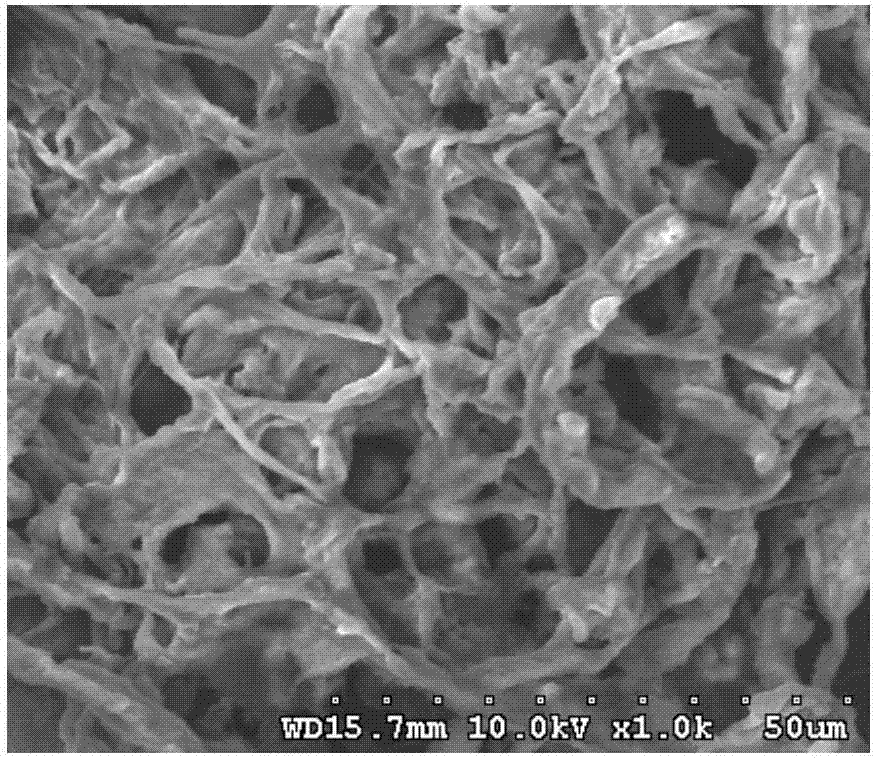

Preparation method and application of banana fiber chitosancomplex hydrogel

A composite hydrogel and banana fiber technology, applied in gel preparation, chemical instruments and methods, water pollutants, etc., can solve problems such as low solubility of cellulose, and achieve fast adsorption speed, strong adsorption capacity, and good biocompatibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

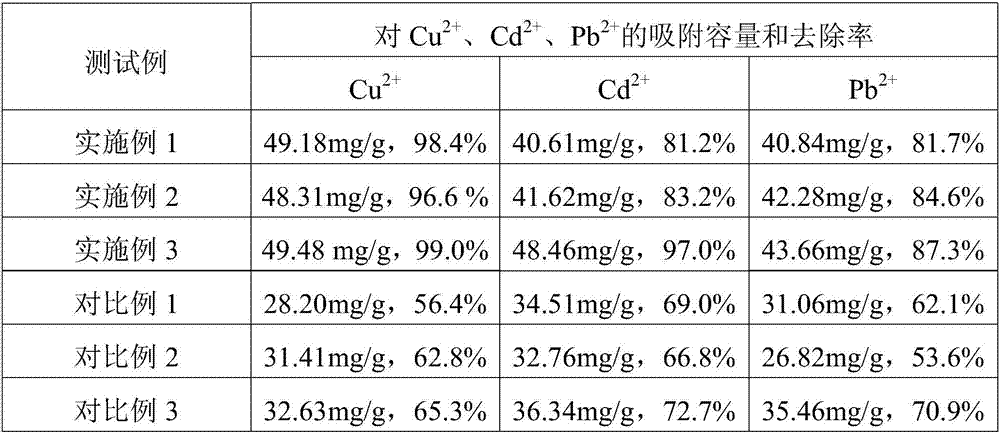

Examples

Embodiment 1

[0025] A preparation method of banana fiber chitosan composite hydrogel, comprising the following steps:

[0026] S1. Purification of banana fiber: after cutting the banana fiber, pickling, secondary alkali boiling, and water washing are carried out to obtain banana cellulose;

[0027] Described pickling is by the sulfuric acid of 1.5g / L, soaks the cut banana fiber at 20 ℃ for 60min, and adds a small amount of penetrating agent JFC (fatty alcohol polyoxyethylene ether), and the banana fiber after pickling is rinsed with deionized water To neutrality; the first time alkali boiling condition of described secondary alkali boiling: in 8%NaOH, 2%Na 2 SiO 3 and 2% Na 2 SO 3 Scouring in the mixed solution for 180min; the second alkali boiling condition: in 2% NaOH, 2% Na 2 CO 3 and 2%H 2 o 2 Scouring in the mixed solution for 120 minutes; the specific operation of the water washing: first wash with distilled water, then wash with 1% dilute sulfuric acid, and finally wash with ...

Embodiment 2

[0034] A preparation method of banana fiber chitosan composite hydrogel, comprising the following steps:

[0035] S1. Purification of banana fiber: after cutting the banana fiber, pickling, secondary alkali boiling, and water washing are carried out to obtain banana cellulose;

[0036]The pickling is 5.0g / L acetic acid, soaking the cut banana fiber at 60°C for 20min, and adding a small amount of penetrant JFC, and washing the pickled banana fiber with deionized water to neutrality; The first alkali boiling condition of soda cooking: in 18% NaOH, 5% Na 2 SiO 3 and 3% Na 2 SO 3 Scouring in the mixed solution for 90 minutes; in the second alkali boiling conditions: 8% NaOH, 5% Na 2 CO 3 and 8%H 2 o 2 Scouring in the mixed solution for 60 minutes; the specific operation of the water washing: first wash with distilled water, then wash with 1% dilute sulfuric acid, and finally wash with distilled water until neutral;

[0037] S2. Banana cellulose dissolution: dissolve the ba...

Embodiment 3

[0043] A preparation method of banana fiber chitosan composite hydrogel, comprising the following steps:

[0044] S1. Purification of banana fiber: after cutting the banana fiber, pickling, secondary alkali boiling, and water washing are carried out to obtain banana cellulose;

[0045] The pickling is 3.0g / L acetic acid, soaking the cut banana fiber for 40min at 40°C, and adding a small amount of penetrant JFC, and washing the pickled banana fiber with deionized water to neutrality; Soda cooking conditions for the first time: in 13% NaOH, 4% Na 2 SiO 3 and 2% Na 2 SO 3 Scouring in the mixed solution for 135min; the second alkali boiling condition: in 5% NaOH, 4% Na 2 CO 3 and 6%H 2 o 2 Scouring in the mixed solution for 90 minutes; the specific operation of the water washing: first wash with distilled water, then wash with 1% dilute sulfuric acid, and finally wash with distilled water until neutral;

[0046] S2. Banana cellulose dissolution: dissolve the banana cellulo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com