Preparation method of oil absorbing material by taking palm fiber as basic material

A technology for oil-absorbing material and palm fiber, which is applied in the field of preparing oil-absorbing material modified with palm fiber as a matrix, can solve the problems of low saturated oil absorption capacity and poor oil-water selectivity, etc., and achieves the effects of high oil absorption performance, low cost and rich pore structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

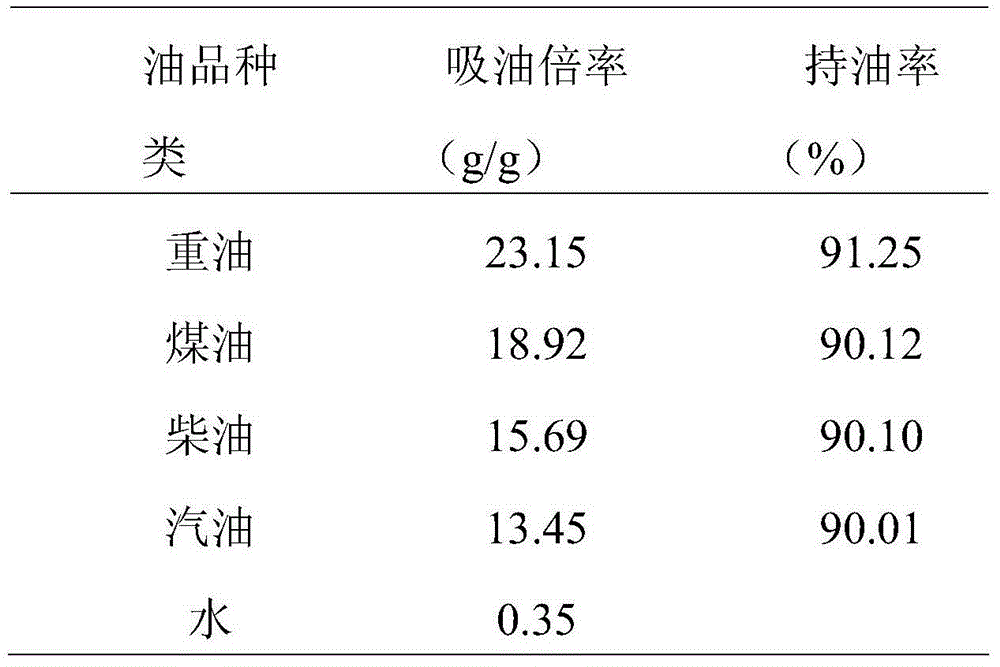

[0038] Use ethyl acetate as the solvent and palm wax as the hydrophobic agent to modify the palm fiber hydrophobic agent to prepare an oil-absorbing material, and test its oil absorption, water absorption and oil retention performance

[0039] (1) Preparation of hydrophobizing agent solution: Take 0.5 g of palm wax into a 500 ml beaker, add 400 ml of ethyl acetate, and heat and dissolve in a constant temperature water bath at 80°C for 30 minutes to obtain a hydrophobizing agent solution.

[0040] (2) Take 10g of the cleaned and dried palm fiber (0.5-5cm) and put it in a hydrophobizing agent at 80℃ for 10 minutes, then take out the palm fiber containing the hydrophobizing agent for rapid drying treatment, and dry it in a microwave oven for 2 minutes to obtain oil absorption material.

[0041] The absorption rate of the product in diesel and water is as follows:

[0042]

Embodiment 2

[0044] Use ethyl acetate as the solvent and paraffin wax as the hydrophobic agent to modify the palm fiber to prepare oil-absorbing material, and test its oil absorption, water absorption and oil retention performance

[0045] (1) Preparation of hydrophobizing agent solution: Take 1g of paraffin wax into a 500ml beaker, add 40ml ethyl acetate, and heat and dissolve in a constant temperature water bath at 80°C for 30 minutes to obtain hydrophobizing agent.

[0046] (2) Take 10g of the cleaned and dried palm fiber (0.5-5cm) and put it in the hydrophobizing agent solution at 20℃ for 120 minutes, then take out the palm fiber containing the hydrophobizing agent and dry it in the microwave oven for 4 minutes to obtain the oil-absorbing material.

[0047] The absorption rate of the product in diesel and water is as follows:

[0048]

Embodiment 3

[0050] Use carbon tetrachloride as solvent and palm wax as hydrophobic agent to modify palm fiber to prepare oil-absorbing material, and test its oil absorption, water absorption and oil retention performance

[0051] (1) Preparation of hydrophobizing agent solution: Take 0.5 g of palm wax into a 500 ml beaker, add 60 ml of carbon tetrachloride, and heat and dissolve in a constant temperature water bath at 70°C for 20 minutes to obtain a hydrophobizing agent solution.

[0052] (2) Take 10g of cleaned and dried palm fiber (0.5-5cm) and immerse it in a hydrophobizing agent solution at 100°C for 30 minutes, then take out the palm fiber containing hydrophobizing agent and perform rapid drying treatment in a microwave oven for 3 minutes to obtain an oil-absorbing material.

[0053] The absorption rate of the product in diesel and water is as follows:

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com