Oil-absorptive resin and oil-absorptive expanding rubber comprising same

An oil-absorbing resin and oil-absorbing swelling technology, which is applied in the field of oil-absorbing swelling rubber, can solve the problems of low compressive strength and achieve high expansion ratio, easy operation, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides an oil-absorbing resin, which comprises the following components in parts by weight:

[0048] 50 parts of butyl methacrylate, 20 parts of lauryl methacrylate, 1.5 parts of diethanol, 1 part of benzoyl peroxide (BPO), 0.01 part of 1,4-butylene glycol diacrylate, 30 parts of water .

[0049] The above-mentioned oil-absorbing resin is prepared by the following method:

[0050] Step 1, adding butyl methacrylate and lauryl methacrylate into the reaction kettle at a temperature of 25° C., stirring evenly to obtain a mixed solution;

[0051] Step 2, adding diethanol, benzoyl peroxide (BPO), and 1,4-butanediol diacrylate in batches to the mixed liquid, adding water as the dispersed phase for dispersion, and stirring to obtain a reaction liquid;

[0052] Step 3: Stir the reaction solution uniformly for 30 minutes before discharging, polymerize after 3 hours to form fluffy particles with small holes inside, and obtain the oil-absorbing resin.

[0053] Th...

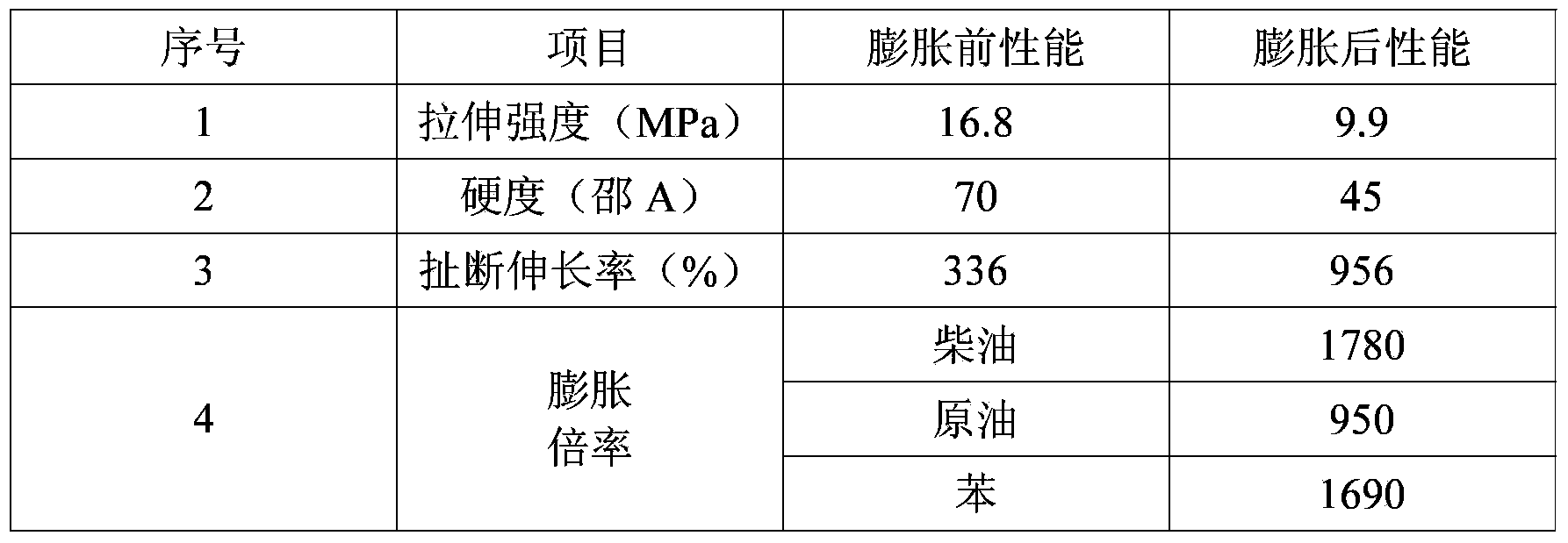

Embodiment 2

[0060] This embodiment provides an oil-absorbing resin, which comprises the following components in parts by weight:

[0061] 60 parts of butyl methacrylate, 10 parts of 2-ethylhexyl acrylate, 15 parts of isobutyl methacrylate, 1.5 parts of diethanol, 1 part of benzoyl peroxide (BPO), 1,4 parts of diacrylic acid - 0.01 part of butanediol ester, 30 parts of water.

[0062] The above-mentioned oil-absorbing resin is prepared by the following method:

[0063] Step 1, adding butyl methacrylate, 2-ethylhexyl acrylate, and isobutyl methacrylate into the reaction kettle at a temperature of 25° C., stirring evenly to obtain a mixed solution;

[0064] Step 2, adding diethanol, benzoyl peroxide (BPO), and 1,4-butanediol diacrylate in batches to the mixed liquid, adding water as the dispersed phase for dispersion, and stirring to obtain a reaction liquid;

[0065] Step 3: Stir the reaction solution uniformly for 20 minutes before discharging, and after 2 hours, polymerize to form fluff...

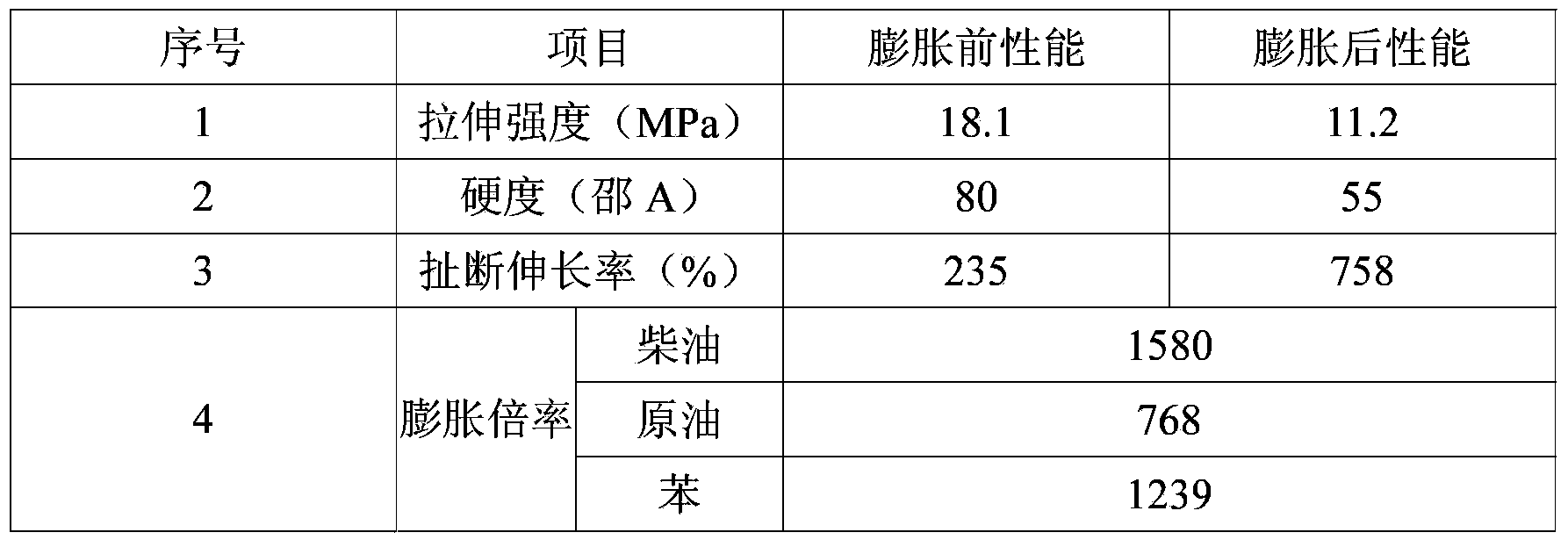

Embodiment 3

[0073] This embodiment provides an oil-absorbing swelling rubber comprising the oil-absorbing resin of Embodiment 1. In parts by weight, the oil-absorbing swelling rubber includes the following components:

[0074] 100 parts of nitrile rubber, 80 parts of oil-absorbing resin, 60 parts of carbon black, 2 parts of stearic acid, 0.5 parts of sulfur, 10 parts of dibutyl phthalate (DBP), tetramethylthiuram disulfide (TMTD) 1 part, 0.5 parts of 2,2'-dithiodibenzothiazole (DM), 1 part of N-isopropyl-N'-phenyl-p-phenylenediamine (4010NA), 8 parts of zinc oxide.

[0075] The above-mentioned oil-absorbing swelling rubber is prepared according to the following steps:

[0076] Step 1: Mix the nitrile rubber and the oil-absorbing resin prepared in Example 1 in an internal mixer, the internal mixer is GK400 type, the internal mixing temperature is controlled at 120-130°C, the rotor speed is controlled at 50r / min, and The top bolt pressure is 0.3MPa, the glue discharge temperature is 90°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com