Method for preparing porous starch with high oil absorption rate through preprocessing starch

A porous starch and pretreatment technology, which is applied in the field of starch industry, can solve the problems of complex preparation process and affecting the overall structure of starch granules, and achieve the effect of simple pretreatment process, reducing irritation and dry feeling, and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

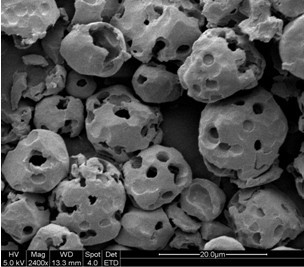

Image

Examples

Embodiment 1

[0022] Add 0.2 mol / L Na with a pH value of 5.4 to 15 g of corn starch 2 HPO 4 -0.1mol / L citric acid buffer 50mL, add two drops of toluene (to prevent starch from sticking to the wall), keep warm and stir at 65°C, preheat for 8 minutes, adjust the temperature to 45°C, add 1.0%-1.2% enzyme solution (α -Amylase:glucoamylase=1:3), the reaction system was reacted at pH 5.4 for 16h, the reaction solution was centrifuged at 4000r / min for 15min, and washed 3 times, the supernatant was discarded, and the precipitate was dried at 40°C , crushed and sieved to obtain the corn porous starch product.

Embodiment 2

[0024] Add 0.2mol / L Na with a pH value of 5.4 to 15g cornstarch 2 HPO 4 -0.1mol / L citric acid buffer 50mL, add two drops of toluene (to prevent starch from sticking to the wall), keep warm and stir at 66°C for 5 minutes, adjust the temperature to 45°C, add 1.0%-1.2% enzyme solution (α -Amylase:glucoamylase=1:3), the reaction system was reacted at pH 5.4 for 16h, the reaction solution was centrifuged at 4000r / min for 15min, and washed 3 times, the supernatant was discarded, and the precipitate was dried at 40°C , crushed and sieved to obtain the corn porous starch product.

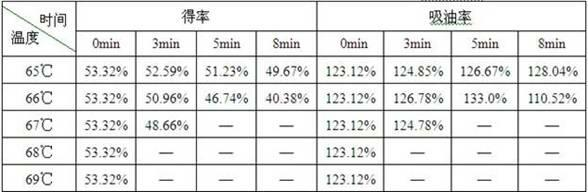

[0025] Table 1 Effects of porous starch pretreatment temperature and time on yield and oil absorption of porous starch

[0026]

[0027] The gelatinization temperature of the corn starch is 70.5°C.

[0028] "—" in the table indicates that the degree of pretreatment is too large, the starch has begun to gelatinize, and the granules are damaged.

Embodiment 3

[0030] Weigh the corn porous starch whose mass is 1 / 5 of the volume of clove oil, slowly add it into the clove oil, stir and adsorb for 1 hour, filter with suction, and vacuum dry at 40°C for 24 hours to obtain powdered clove oil. The powdered clove oil is added to the tobacco sheet raw material in an amount of 2.0 mg clove oil porous starch powder / g tobacco sheet to make slow-release cigarettes. During the transfer of clove oil during cigarette smoking, the toxicological test and sensory evaluation test were carried out according to the medical science. The results showed that there was no toxicological reaction and it had a slow-release effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com