Preparation method of ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption

A technology of cellulose airgel and nanofibrillation, which is applied in the direction of coating, etc., can solve the problems of low oil absorption rate and strong hydrophilicity, and achieve the effects of high oil absorption rate, high safety and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

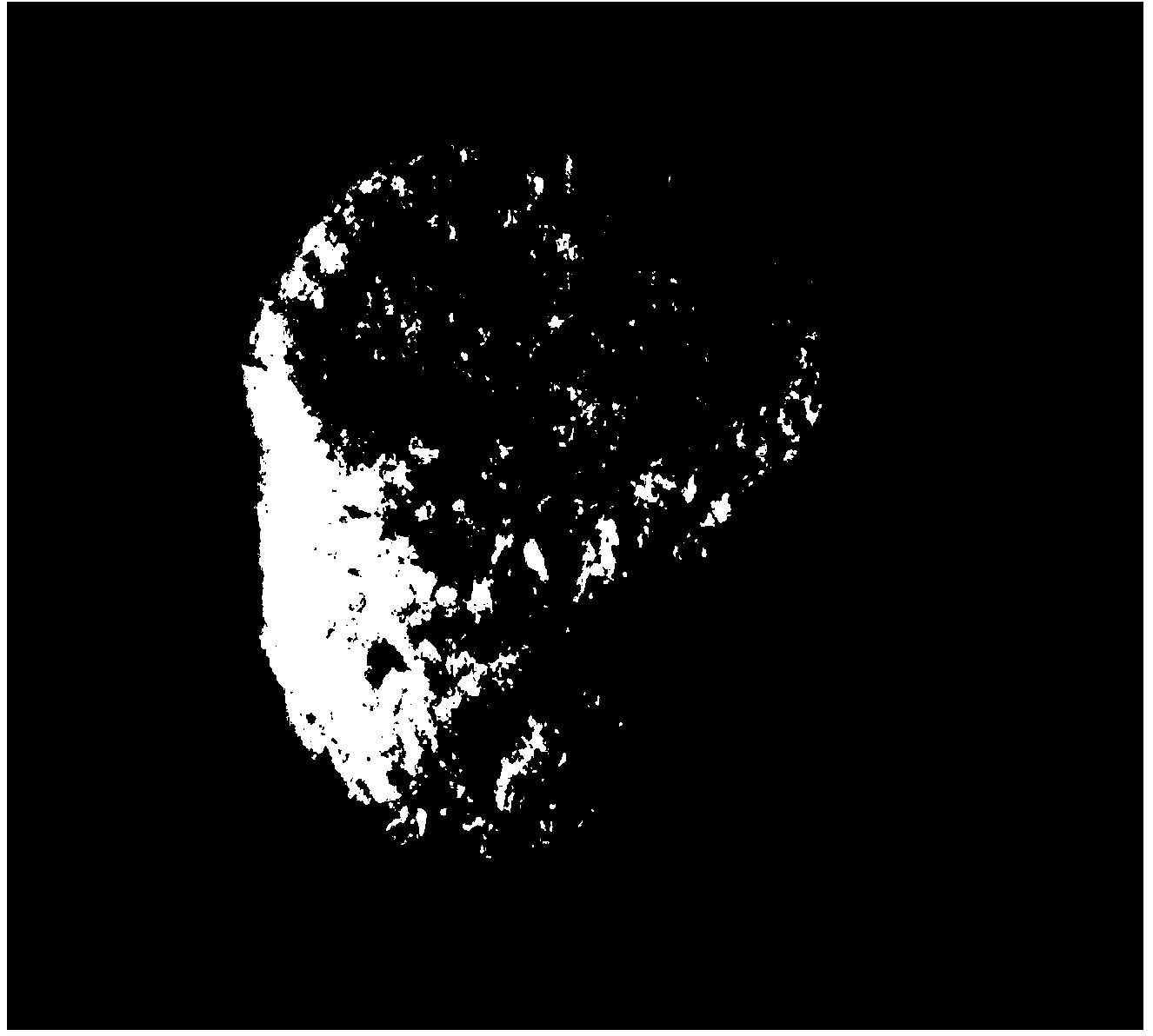

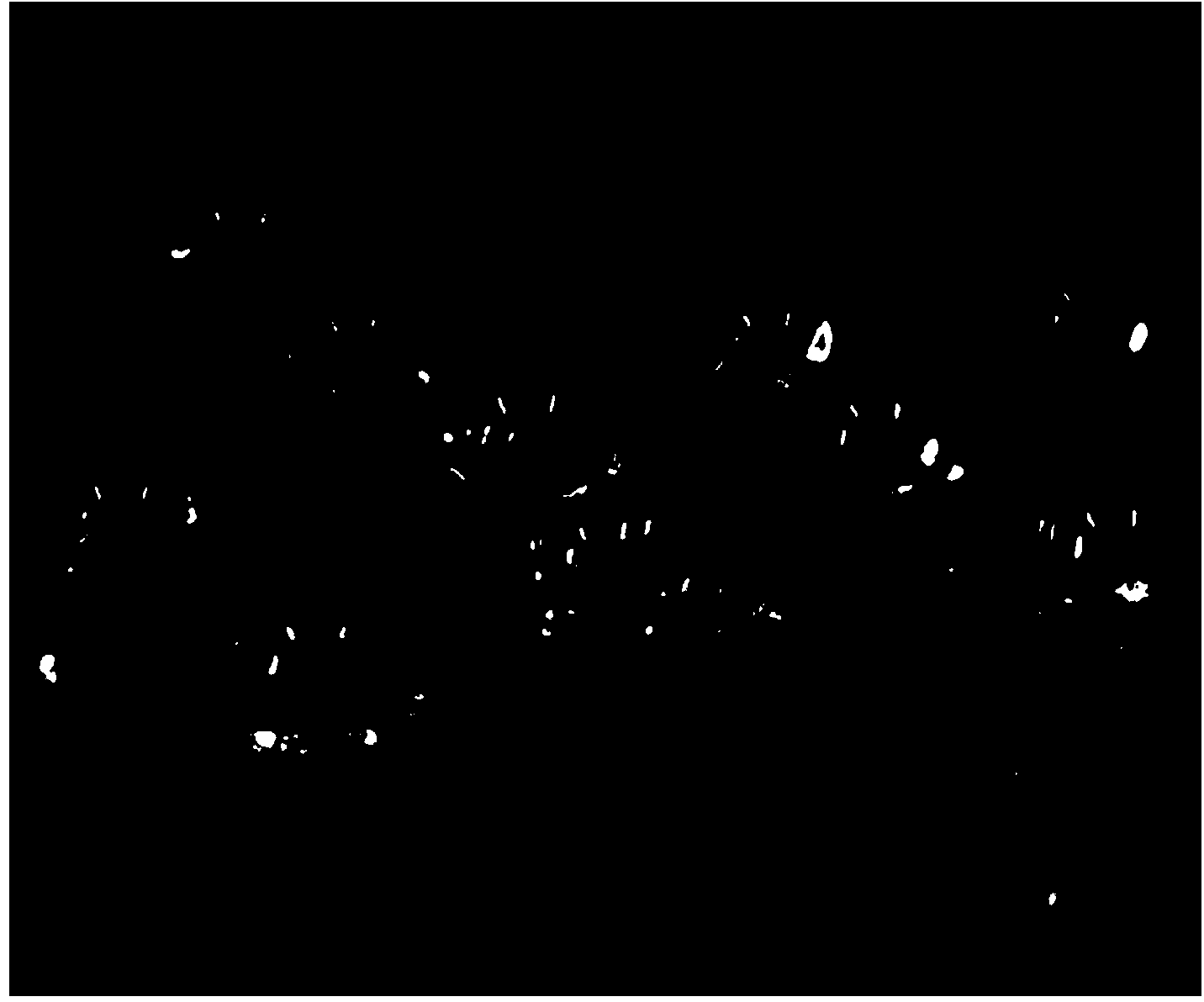

Image

Examples

specific Embodiment approach 1

[0022] Embodiment 1: The preparation method of a nano-fibrillated cellulose airgel described in this embodiment is ultra-light, hydrophobic, and high oil absorption, specifically according to the following steps:

[0023] 1. Preparation of cellulose aqueous solution: weigh 1 to 100 parts of cellulose and 100 to 10,000 parts of water in parts by mass; add 1 to 100 parts of cellulose to 100 to 10,000 parts of water, and stir Uniformly, obtain cellulose aqueous solution;

[0024] 2. Preparation of nanofibrillated cellulose aqueous dispersion: ①. Put the cellulose aqueous solution into an ultrasonic cell crusher with a temperature of -100°C to 100°C and an output power of 10W to 1000W; ②. ℃~100℃ and an ultrasonic cell disruptor with an output power of 10W~1000W, after ultrasonic treatment for 0.01s~60s, suspend the ultrasonic treatment for 0.01s~60s; The ultrasonic treatment time is the total working time, and step 2② is carried out in a cycle until the total working time is 1 mi...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that the cellulose described in step 1 is obtained by chemical purification using coconut shell, cotton, filter paper, bamboo fiber, pulp, wood or straw as raw materials. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the water described in step 1 is distilled water, deionized water or ultrapure water. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com