Hydrophilic oil absorption cotton

An oil-absorbing cotton, hydrophilic and lipophilic technology, applied in the field of materials, can solve problems such as the inability to filter oil stains and other impurities in water at the same time, the oil absorption cannot satisfy users to filter oil stains and impurities at the same time, and the use of oil-absorbing materials to achieve high oil absorption rate. , The effect of improving oil absorption rate and improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

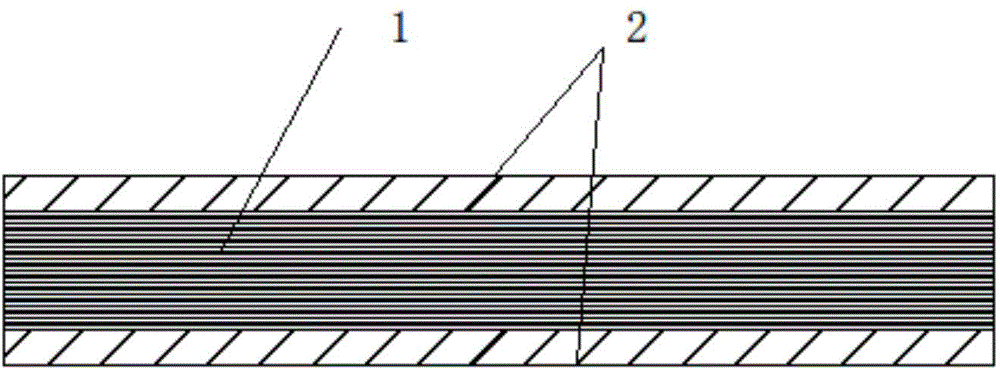

[0019] In one embodiment, a kind of hydrophilic oil-absorbing cotton, such as figure 1 As shown, it is composed of a hydrophilic and lipophilic auxiliary agent layer 1 and a filter layer 2 wrapping the auxiliary agent layer;

[0020] The hydrophilic and lipophilic additive layer 1 is made of super amphiphilic material, and the filter layer 2 is made of composite filter cotton.

[0021] Preferably, the super-amphiphilic material is a nano-scale composite material, which contains a nano-scale space composed of regularly arranged hydrophilic polymer segments and lipophilic polymer segments, and can incorporate tiny particles wrapped in it.

[0022] Preferably, the composite material is a sparse porous structure with a pore size of 50 nm.

[0023] Preferably, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com