Wooden sponge oil-absorbing material and preparation method thereof

An oil-absorbing material and sponge technology, which is applied in wood treatment, wood impregnation, separation methods, etc., can solve the problems of poor mechanical properties of cellulose aerogel, unfavorable oil-absorbing material reuse, complicated raw material preparation process, etc., and achieves the reuse performance. Good, good promotion and application prospect, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

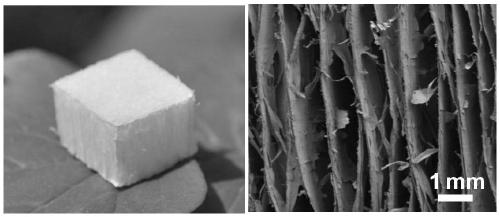

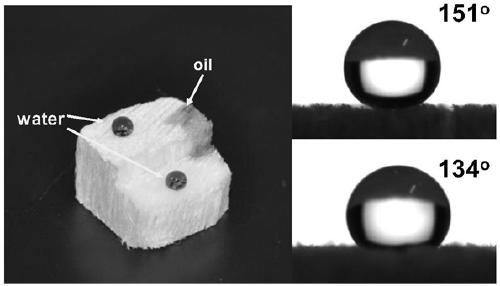

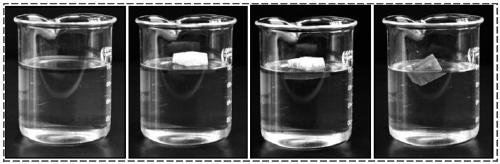

[0028] Embodiment 1: A kind of wooden sponge oil-absorbing material

[0029] Put the block wood with a size of 1.50mm×1.5mm×1.5mm into a hydrogen peroxide solution with a concentration of 30%, and heat it at 60°C for 8 hours to obtain bleached wood;

[0030] Sodium chlorite (NaClO) with a concentration of 2% 2 ) solution, and adjust the pH value to 4.0 with phosphoric acid, immerse the above-mentioned bleached wood in an acidic sodium chlorite solution, and cook at 80°C for 3 hours to remove the lignin component in the wood cell wall; the above-mentioned delignified wood Put it into 8% sodium hydroxide solution, and treat it at 80°C for 8 hours to further remove hemicellulose.

[0031] After the above-mentioned treated wood was washed with distilled water several times, it was frozen in a refrigerator for 8 hours, and then moved to a vacuum freeze dryer for freeze-drying for 30 hours. The temperature of the cold trap was minus 40°C, and the vacuum was 5Pa. The prepared woode...

Embodiment 2

[0036]Embodiment 2: a kind of preparation method of wooden sponge oil-absorbing material, the steps are:

[0037] (1) Wood bleaching: use balsa wood as a raw material, process it into block or flake samples, put it into a hydrogen peroxide solution, and heat it;

[0038] (2) Remove lignin: immerse the above-mentioned bleached wood in acidic sodium chlorite solution and cook for 5 hours;

[0039] (3) Hemicellulose removal: put the above-mentioned delignified wood into sodium hydroxide solution, and treat it at 55°C for 8 hours;

[0040] (4) freeze-drying: the timber after step (3) is processed, puts into freeze-drying 25 hours in the vacuum freeze-drying machine after washing with water;

[0041] (5) Silanization treatment: put the container containing methyltrichlorosilane into the bottom of the airtight container, put the material obtained in step (4) into the airtight container, heat to 80°C for silanization modification, and the treatment time is 3 hours , that is.

Embodiment 3

[0042] Embodiment 3: a kind of preparation method of wooden sponge oil-absorbing material, the steps are:

[0043] (1) Wood bleaching: use balsa wood as a raw material, process it into block or flake samples, put it into a hydrogen peroxide solution, and heat it;

[0044] (2) Removal of lignin: immerse the above-mentioned bleached wood in an acidic sodium chlorite solution and cook for 4 hours;

[0045] (3) Hemicellulose removal: put the above-mentioned delignified wood into sodium hydroxide solution, and treat it at 50-85° C. for 7 hours;

[0046] (4) freeze-drying: the wood after step (3) is processed, puts into vacuum freeze-drying machine freeze-drying 24 hours after water washing;

[0047] (5) Silanization treatment: put the container containing methyltrichlorosilane into the bottom of the airtight container, put the material obtained in step (4) into the airtight container, heat to 90°C for silanization modification, and the treatment time is 1 hour , that is;

[0048...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com