Open-cell polymer foam material and preparation method therefor

A foam material and open-cell foam technology, which is applied in the field of open-cell polymer foam material and its preparation, can solve the problems of difficult to achieve high oil absorption ratio, complex preparation process, and low open cell ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of open cell polymer foam material, it comprises the steps:

[0028] a Weigh 100 parts by weight of polypropylene, 0.5 to 5 parts by weight of nucleating agent, 10 to 100 parts by weight of polyolefin containing ethylene, and 1 to 30 parts by weight of open-cell filler;

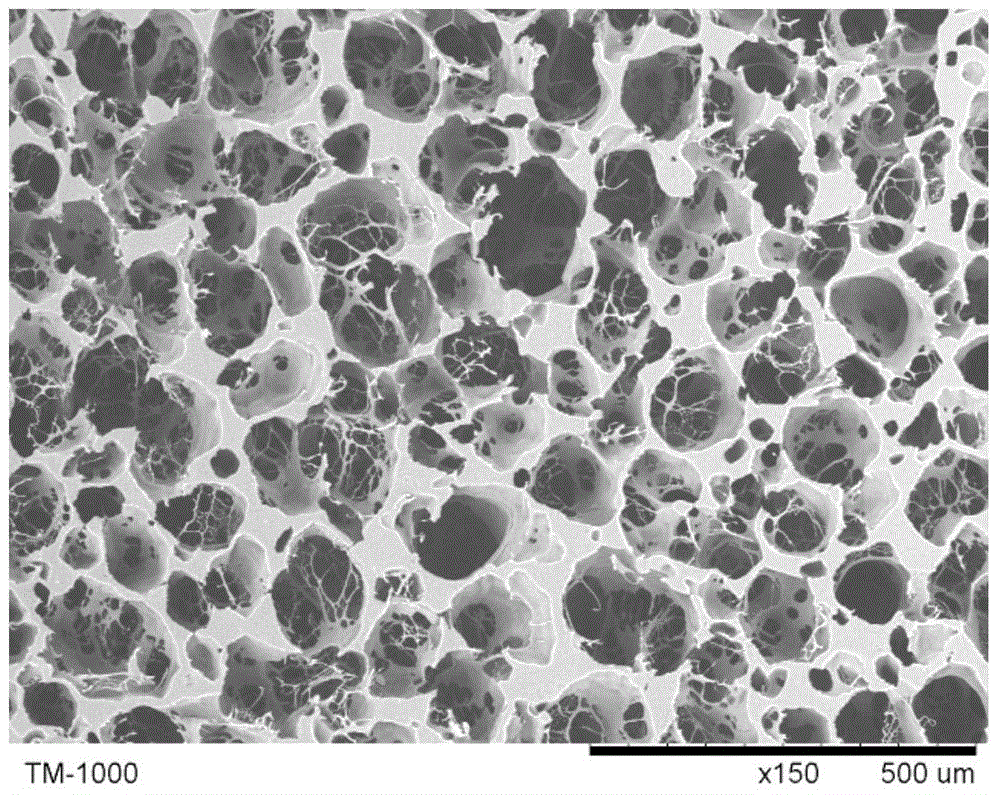

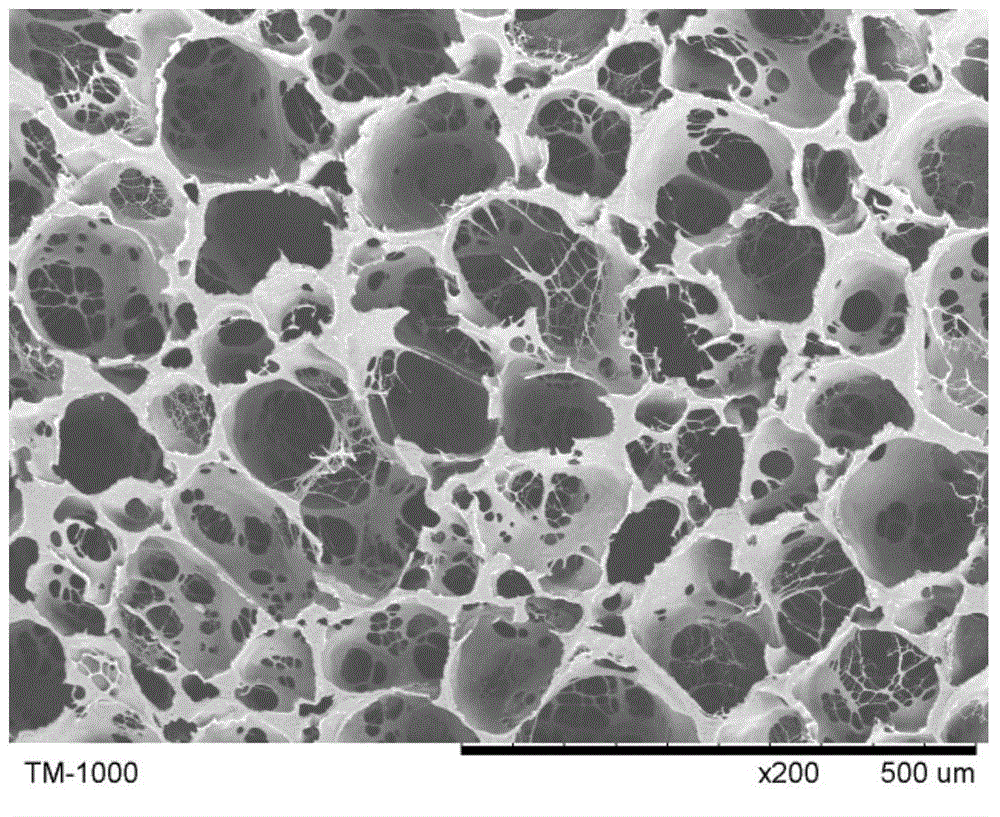

[0029] b Uniformly mix the polypropylene, nucleating agent, ethylene-containing polyolefin and open-cell filler to obtain a mixture, then add the mixture into an extruder, and place the mixture in 1 / 5 to 1 / 3 is passed into supercritical carbon dioxide, extruded and foamed to obtain an open-cell polymer foam material containing open-cell filler, and the open-cell polymer foam material containing open-cell filler includes a plurality of first open cells ;

[0030] c. Immersing the open-cell foam material containing the open-cell filler in an etching solution, so that the open-cell filler in the open-cell foam material containing the open-cell filler i...

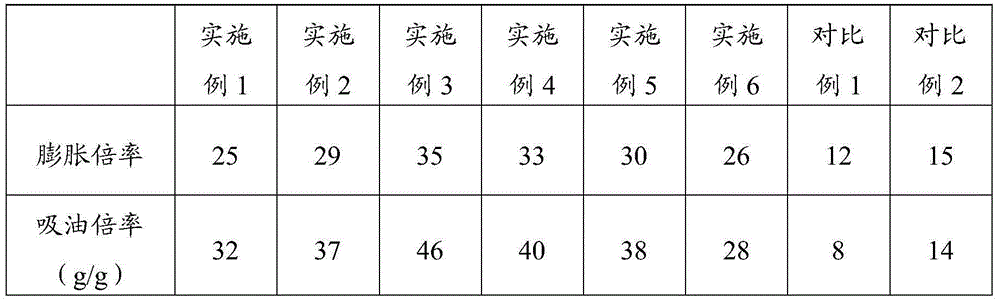

Embodiment 1

[0045] Weigh 100 parts by weight of polypropylene, 0.5 parts by weight of talcum powder, 30 parts by weight of linear low density polyethylene and 5 parts by weight of calcium carbonate.

[0046] The above-mentioned raw materials are dry mixed and added to the extruder; wherein, the screw speed is set to 30rad / min, the temperature in the first half of the screw is set to 190°C, and the temperature in the second half of the screw is set to 165°C; 10 parts by weight of supercritical carbon dioxide was injected into 4 places, the injection pressure was set at 15 MPa, and an open-cell polymer foam material containing open-cell filler was obtained by extrusion and foaming.

[0047] Then soak the open-cell polymer foam material containing the open-cell filler in dilute sulfuric acid solution with a molar concentration of 1.5 mol / L and etch for 16 hours to obtain the open-cell polymer foam material.

Embodiment 2

[0049] 100 parts by weight of polypropylene, 0.7 parts by weight of nanoclay, 80 parts by weight of linear low density polyethylene and 10 parts by weight of magnesium carbonate were weighed.

[0050] Dry mix the above raw materials and add them into the extruder; wherein, the screw speed is set to 50rad / min, the temperature in the first half of the screw is set to 210°C, and the temperature in the second half of the screw is set to 155°C; 12 parts by weight of supercritical carbon dioxide were injected into 4 places, the injection pressure was set at 18 MPa, and an open-cell polymer foam material containing open-cell filler was obtained by extrusion and foaming.

[0051] Then soak the open-cell polymer foam material containing the open-cell filler in a nitric acid solution with a molar concentration of 3.5 mol / L and etch for 20 hours to obtain the open-cell polymer foam material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com