Method for preparing silicon epitaxial wafer for step recovery diode

A technology for recovering diodes and silicon epitaxial wafers, used in chemical instruments and methods, semiconductor/solid-state device manufacturing, crystal growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

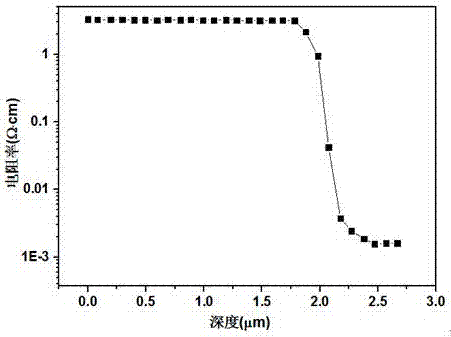

Embodiment 1

[0023] (1) First use hydrogen chloride (HCl) gas with a purity ≥ 99.99% to etch the graphite base of the epitaxial furnace to completely remove the residual deposited substances on the base, set the etching temperature to 1130°C, and set the HCl gas flow rate to was 3 L / min, and the HCl etching time was set to 3 min. Immediately after the etching is completed, a layer of undoped polysilicon is re-grown on the surface of the base, and the growth material is SiHCl 3 , the flow rate is set to 15 L / min, and the time is set to 10 min.

[0024] (2) Load the silicon single crystal substrate into the pit of the base of the epitaxial furnace, and use nitrogen and hydrogen with a purity of ≥99.999% to purge the reaction chamber of the epitaxial furnace in sequence. The gas flow rate is set to 300 L / min, and the purge time is for 10 min.

[0025] (3) The surface of the silicon single crystal substrate was polished with HCl, the HCl flow rate was set to 1 L / min, the polishing temperatur...

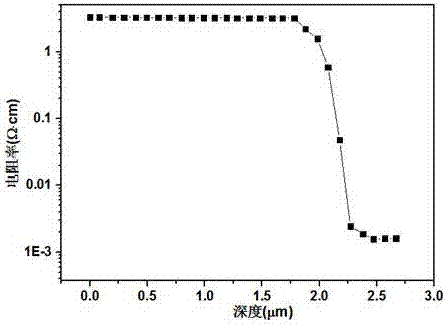

Embodiment 2

[0034] (1) First use hydrogen chloride (HCl) gas with a purity ≥ 99.99% to etch the graphite base of the epitaxial furnace to completely remove the residual deposited substances on the base, set the etching temperature to 1130°C, and set the HCl gas flow rate to was 1 L / min, and the HCl etching time was set to 3 min. Immediately after the etching is completed, a layer of undoped polysilicon is re-grown on the surface of the base, and the growth material is SiHCl 3 , the flow rate is set to 14 L / min, and the time is set to 12 min.

[0035] (2) Load the silicon single crystal substrate into the pit of the base of the epitaxial furnace, and use nitrogen and hydrogen with a purity of ≥99.999% to purge the reaction chamber of the epitaxial furnace in sequence. The gas flow rate is set to 300 L / min, and the purge time is for 12 min.

[0036] (3) The surface of the silicon single crystal substrate was polished with HCl, the HCl flow rate was set to 1 L / min, the polishing temperatur...

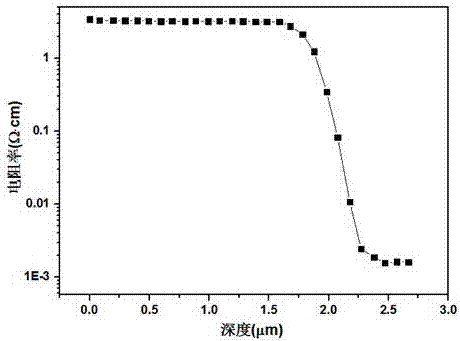

Embodiment 3

[0045] (1) First use hydrogen chloride (HCl) gas with a purity of ≥99.99% to etch the base of the epitaxial furnace to completely remove the residual deposits on the base, set the etching temperature to 1130°C, and set the HCl gas flow rate to 3 L / min, HCl etching time is set to 3 min. Immediately after the etching is completed, a layer of undoped polysilicon is re-grown on the surface of the base, and the growth material is SiHCl 3 , the flow rate was set at 15 L / min, and the growth time was set at 10 min.

[0046] (2) Load the silicon single crystal substrate into the pit of the base of the epitaxial furnace, and use nitrogen and hydrogen with a purity of ≥99.999% to purge the chamber in sequence. The gas flow rate is set to 300 L / min, and the purge time is 10 min. .

[0047] (3) The surface of the silicon single crystal substrate was polished with HCl, the HCl flow rate was set to 1 L / min, the polishing temperature was set to 1130 °C, and the polishing time was set to 3 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com