Surface acoustic wave device and production method thereof and mobile communication equipment using it

A surface acoustic wave and device technology, which is applied to machines/engines, electrical components, engine components, etc., can solve problems such as the increase in electrode specific resistance, the rise in chip temperature, and the stability of the electrical characteristics of SAW devices. The effect of higher electrical power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

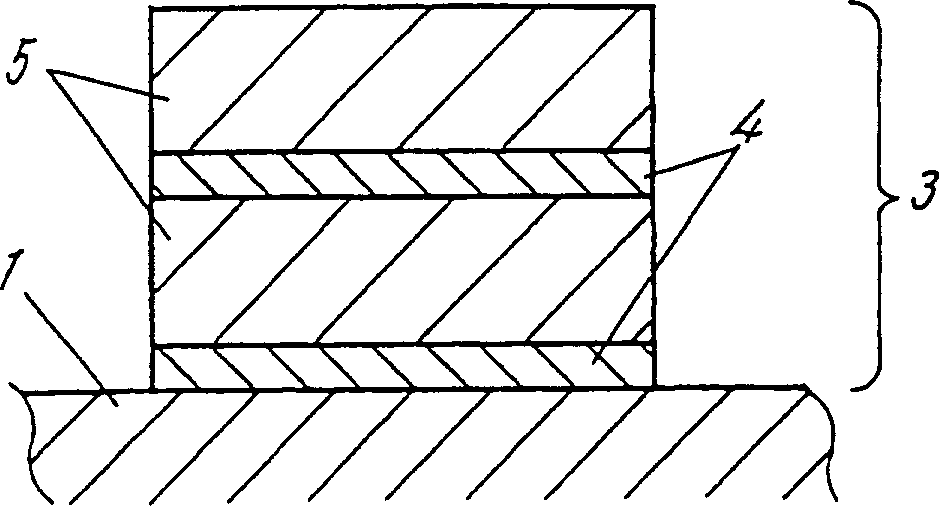

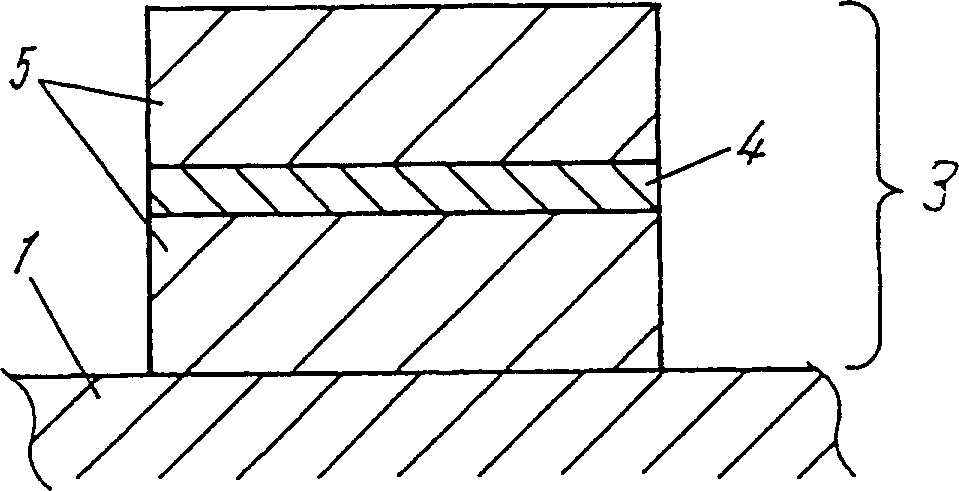

[0047] (Example 1) Titanium was used for the first metal layer, and an alloy of Al-0.15% by weight Sc-1.0% by weight of Cu was used for the second metal layer.

Embodiment 2

[0048] (Example 2) An alloy in which titanium was added with 0.5% by weight of Al was used for the first metal layer, and an alloy of Al-0.15% by weight of Sc-1.0% by weight of Cu was used for the second metal layer.

[0049] Here, Sc contained in the second metal layer is a metal that dissolves in aluminum at room temperature, and Cu is used as a metal that segregates at grain boundaries of aluminum or forms an intermetallic compound with aluminum at room temperature.

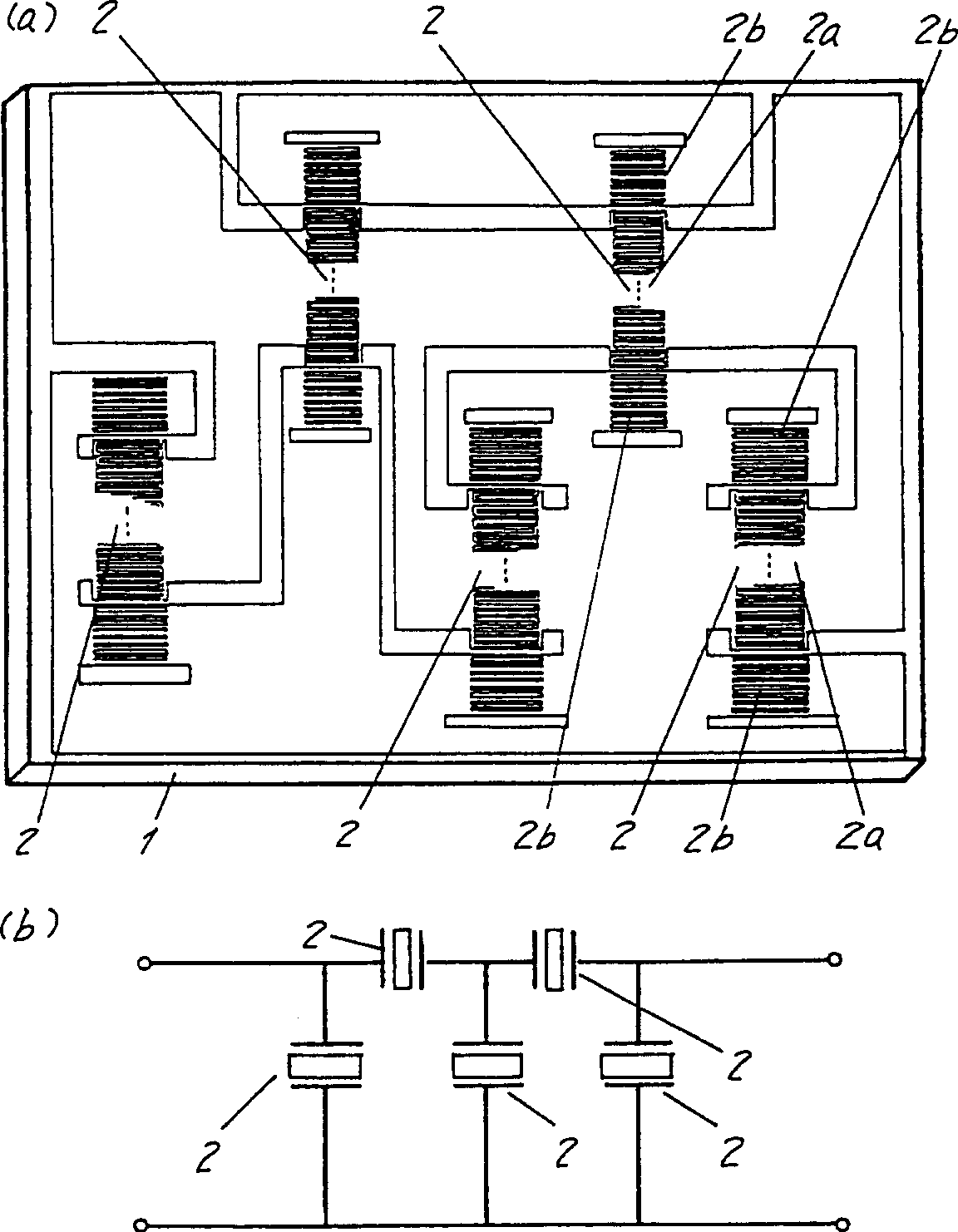

[0050] Also, for comparison at the same time, the following SAW filter was fabricated according to the electrode structure of FIG. 2 .

Embodiment 3

[0072] (Example 3) Titanium was used for the first metal layer, and an alloy of Al-0.15% by weight Sc-1.0% by weight of Cu was used for the second metal layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com