Semiconductor laser device and optical pick-up apparatus using semiconductor laser device

A technology of lasers and semiconductors, which is applied to semiconductor lasers, structural details of semiconductor lasers, semiconductor devices, etc., can solve problems such as difficulty in maintaining bonding strength, difficulty in ensuring positional accuracy, and complicated processes, and achieve good heat dissipation, low performance, and The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

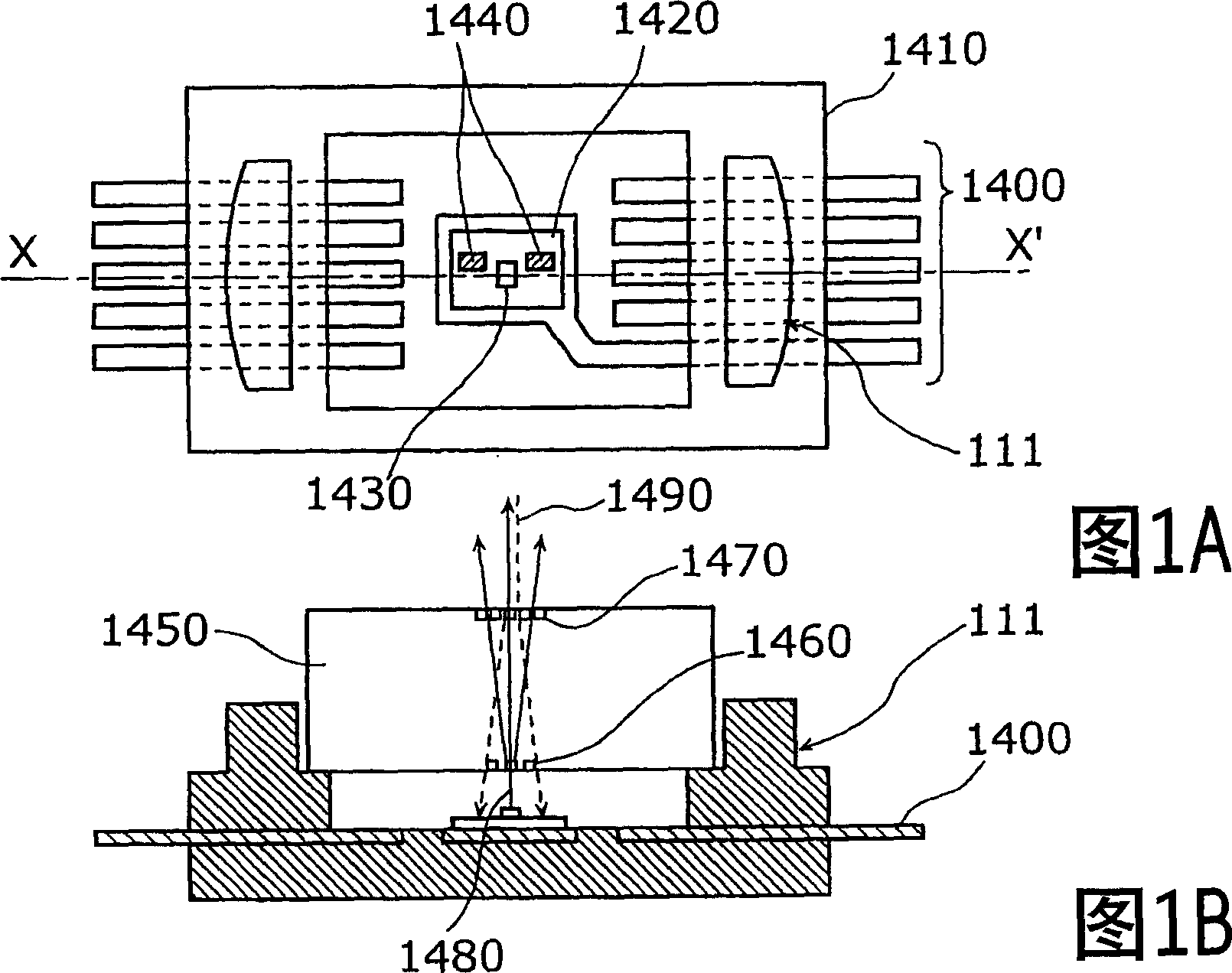

[0103] 4A is a plan view of the semiconductor laser module of the first embodiment, and FIG. 4B is a cross-sectional view of the semiconductor laser module (cross-sectional view taken along line X-X' in FIG. 4A ).

[0104] The object of the semiconductor laser module of the present embodiment is to realize a semiconductor laser module that is easy to dissipate heat, and can have both high functionality and miniaturization. It has: metal plate 100, made of copper, nickel and gold are electroplated on the surface; semiconductor laser 110; photosensitive element and signal processing circuit; the flexible thin plate 130 is wired with metal such as copper and clamped with resin such as polyimide; the metal wire 140 is formed by gold wire, and the semiconductor laser 110, the silicon substrate 120 and the flexible The thin plates 130 are electrically connected to each other; the optical element 150 such as a glass substrate transmits the light emitted from the semiconductor laser 1...

no. 2 approach

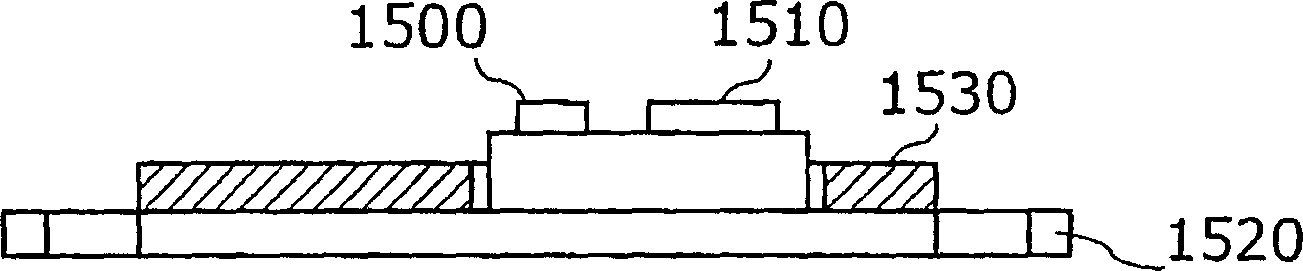

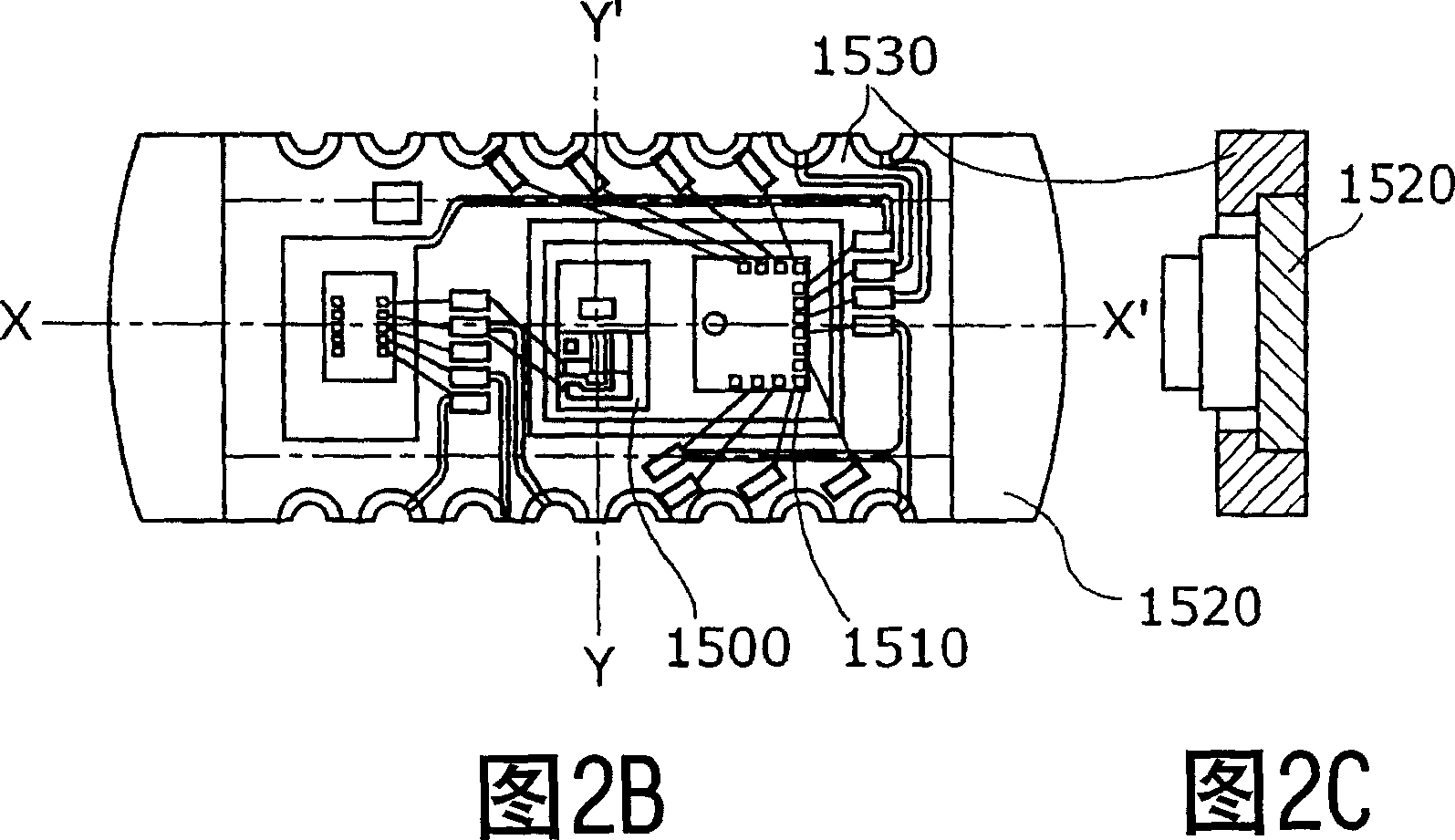

[0118]5A is a plan view of the semiconductor laser module of the second embodiment, and FIG. 5B is a cross-sectional view of the semiconductor laser module (cross-sectional view taken along line X-X' in FIG. 5A ). In addition, the same reference numerals are assigned to the same components as those in FIGS. 4A and 4B , and detailed description thereof will be omitted.

[0119] The difference between the semiconductor laser module of this embodiment and the semiconductor laser module of the above-mentioned first embodiment is that the reinforcing member provided with the optical element is provided on a flexible thin plate, and the semiconductor laser module has a metal plate 100, Semiconductor laser 110 , silicon substrate 120 , flexible thin plate 130 , metal wire 140 , optical element 200 such as a glass substrate that transmits light emitted from semiconductor laser 110 and light incident on a photosensitive element, and reinforcing member 210 .

[0120] The optical element...

no. 3 approach

[0125] Figure 6 It is a plan view of the semiconductor laser module of the third embodiment. In addition, the same reference numerals are assigned to the same components as those in FIGS. 5A and 5B , and detailed description thereof will be omitted.

[0126] The difference between the semiconductor laser module of this embodiment and the semiconductor laser module of the above-mentioned second embodiment is that the flexible thin plate is subjected to easy bending processing, and the semiconductor laser module has a metal plate 100, a semiconductor laser 110, a silicon substrate, and a metal plate 100. 120 , a flexible thin plate 130 , an optical element 200 , and a semicircular bending guide groove 300 formed on the bending portion of the flexible thin plate 130 outside the metal plate 100 as a bending point.

[0127] As described above, according to the semiconductor laser module of the present embodiment, the guide groove 300 serving as the starting point of bending is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com