Magnesium-base composite refractory raw material and preparation method thereof

A refractory raw material and raw material technology, applied in the field of magnesium-based composite refractory raw materials and its preparation, can solve the problems of reducing the high-temperature performance and slag erosion resistance of magnesia materials, limiting the application of magnesia materials, etc., so as to improve the comprehensive utilization rate, Improved thermal shock resistance and improved thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

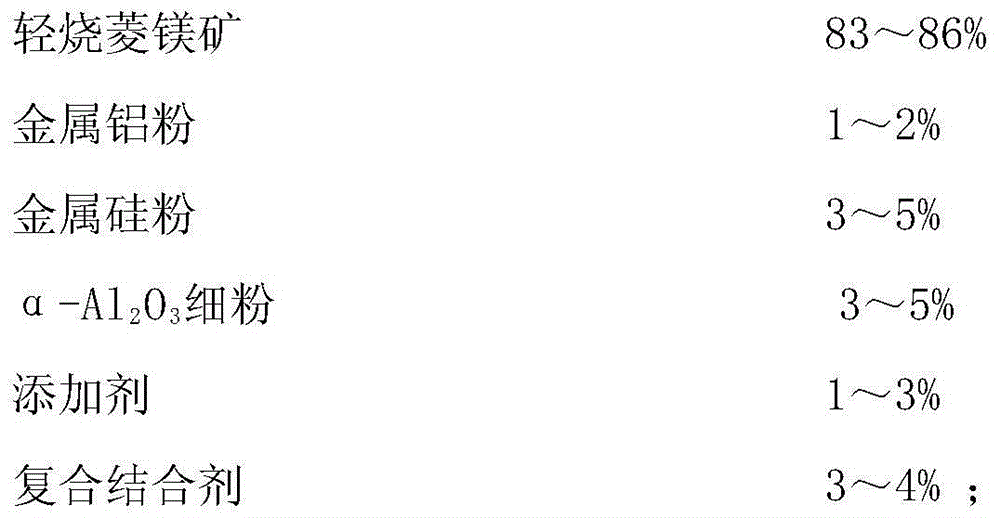

Method used

Image

Examples

Embodiment 1

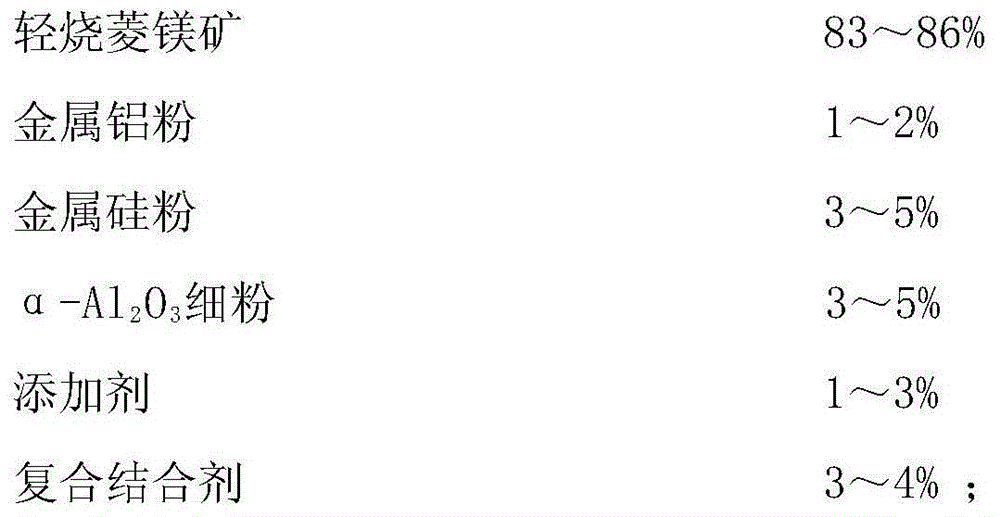

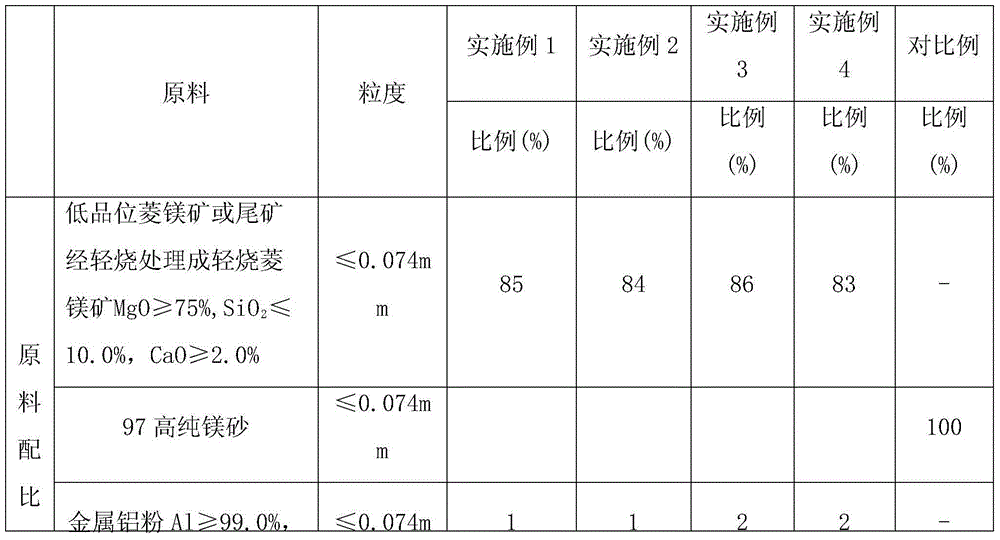

[0034] A magnesium-based composite refractory raw material, the chemical composition of the raw material and the weight percentage content of each component are shown in Example 1 in Table 1, wherein the composite binder consists of 30% ethylene glycol and 70% phenolic formaldehyde by weight percentage Made of resin.

[0035] A preparation method of magnesium-based composite refractory material, the steps of the method are as follows:

[0036] A. by the chemical composition and weight percent of Table 1 embodiment 1, take by weighing various materials;

[0037] b. Put low-grade magnesite or tailings in a muffle furnace and lightly burn at 900°C to obtain lightly burned magnesite;

[0038] c. Co-grind light-burned magnesite and compound additives in a ball mill, and the powder output rate is ≤10t / h;

[0039] d. Lightly burnt magnesite, metal aluminum powder, α-Al 2 o 3 Fine powder and additives are mixed, and the mixed material is added to a composite binder, and pressed in...

Embodiment 2

[0043] A magnesium-based composite refractory raw material, the chemical composition of the raw material and the weight percentage content of each component are shown in Example 2 in Table 1, wherein the composite binder consists of 50% ethylene glycol and 50% phenolic formaldehyde by weight percentage Made of resin.

[0044] A preparation method of magnesium-based composite refractory material, the steps of the method are as follows:

[0045] A. by the chemical composition and weight percent of Table 1 embodiment 2, take by weighing various materials;

[0046] b. Put low-grade magnesite or tailings in a muffle furnace and lightly burn at 900°C to obtain lightly burned magnesite;

[0047] c. Co-grind light-burned magnesite and compound additives in a ball mill, and the powder output rate is ≤10t / h;

[0048] d. Lightly burnt magnesite, metal aluminum powder, α-Al 2 o 3 Fine powder and additives are mixed, and the mixed material is added to a composite binder, and pressed in...

Embodiment 3

[0052] A magnesium-based composite refractory raw material, the chemical components of the raw material and the weight percentage content of each component are shown in Example 3 in Table 1, wherein the composite binder consists of 40% ethylene glycol and 60% phenolic formaldehyde by weight percentage Made of resin.

[0053] A preparation method of magnesium-based composite refractory material, the steps of the method are as follows:

[0054] A. by the chemical composition and weight percent of table 1 embodiment 3, take by weighing various materials;

[0055] b. Put low-grade magnesite or tailings in a muffle furnace and lightly burn at 900°C to obtain lightly burned magnesite;

[0056] c. Co-grind light-burned magnesite and compound additives in a ball mill, and the powder output rate is ≤10t / h;

[0057] d. Lightly burnt magnesite, metal aluminum powder, α-Al 2 o 3 Fine powder and additives are mixed, and the mixed material is added to a composite binder, and pressed int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com