Self diffusion spreading oil on water surfaces and preparation method thereof

A film-spreading oil and self-diffusion technology, applied in the fields of botanical equipment and methods, insecticides, biocides, etc., can solve the problems of surrounding environment pollution, environmental pollution, residues, etc., and reduce labor intensity and preparation cost. , the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of 6% penoxsulam·cyhalofop-ester spreading oil:

[0023] Step (1) is equipped with the following raw materials in weight percentage: penoxsulam 1%, cyhalofop-methyl 5%, fatty alcohol succinate sulfonate 20%, polycarboxylate 1%, block polyether 2 %, organic bentonite 2%, and ethyl oleate make up to 100%.

[0024] Step (2) Add penoxsulam, cyhalofop-methyl, fatty alcohol succinate sulfonate, polycarboxylate, epoxy polyether, organic bentonite and ethyl oleate into the high shear emulsifier , mixed by a high-shear emulsifier, and then sanded in a sand mill to obtain 6% penoxsulam·cyhalofop-ester spreading oil.

[0025] According to the same preparation process steps as in Example 1, the following examples can be prepared.

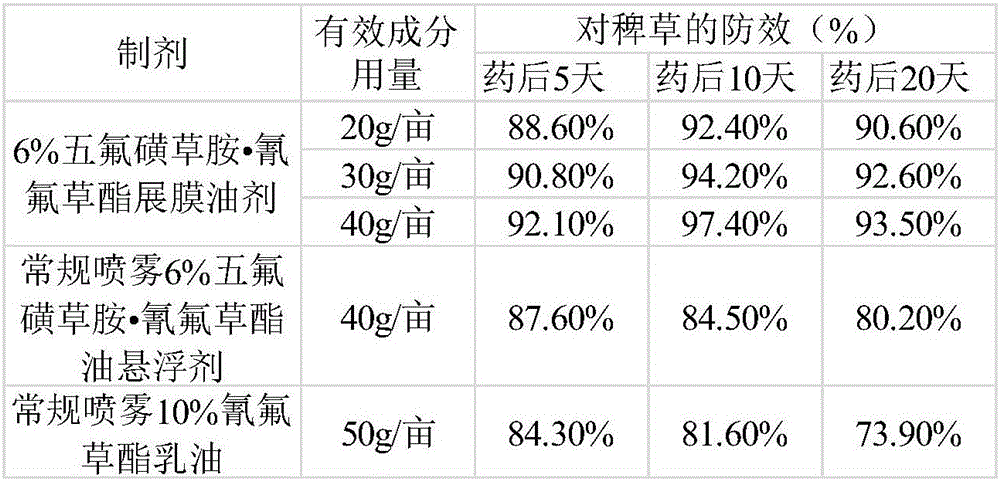

[0026] The control effects of 6% penoxsulam·cyhalofop-ester spreading film oil and conventional spraying on barnyardgrass in the present invention are shown in Table 1:

[0027] Table 1

[0028]

[0029] It can be seen from Table 1 tha...

Embodiment 2

[0031] Preparation of 5% Etofenprox Film Spreading Oil Process Reference Example 1:

[0032] Step (1) is equipped with the following raw materials in weight percentage: 5% of etofenprox, 20% of fatty alcohol polyether, 0.5% of lignosulfonate, 2% of organobentonite, and 100% of methyl oleate.

[0033] Step (2) Add etofenproxil, fatty alcohol polyether, lignosulfonate, organic bentonite, and methyl oleate into a high-shear emulsifier, and mix them in a sand mill After sanding, 5% etofenprox spreading oil can be obtained.

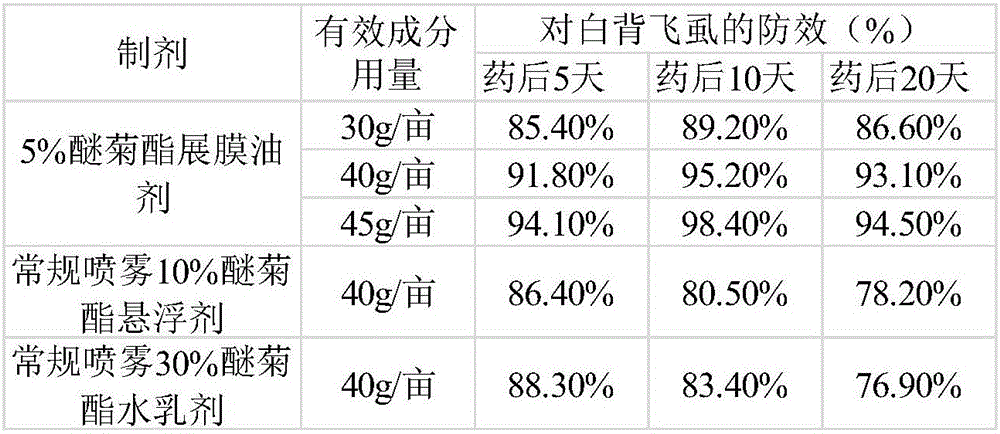

[0034] In the present invention, the control effects of 5% etofenprox film spreading oil and conventional spraying on white-backed planthopper are as shown in table 2:

[0035] Table 2

[0036]

[0037] It can be seen from Table 2 that the control effect on white-backed planthopper after application of 5% etofenprox film spreading oil is better than that of conventional spray with the same active ingredient, and the synergistic control effect on white-bac...

Embodiment 3

[0039] Preparation of 12.6% Buprofezin · Emamectin Salt Film Spreading Oil:

[0040] Step (1) is equipped with the raw material of following percentage by weight: Buprofezin 12%, emamectin 0.6%, fatty alcohol succinate sulfonate 20%, polycarboxylate 2%, fatty alcohol 2%, magnesium silicate 0.5% of aluminum and 100% of methyl oleate.

[0041] Step (2) Add buprofezin, emamectin benzoate, fatty alcohol succinate sulfonate, polycarboxylate, fatty alcohol, magnesium aluminum silicate, and methyl oleate into a high-shear emulsifier, and After mixing in a shearing emulsifier, the 12.6% buprofezin·amamectin salt film-developing oil can be obtained after sanding in a sand mill.

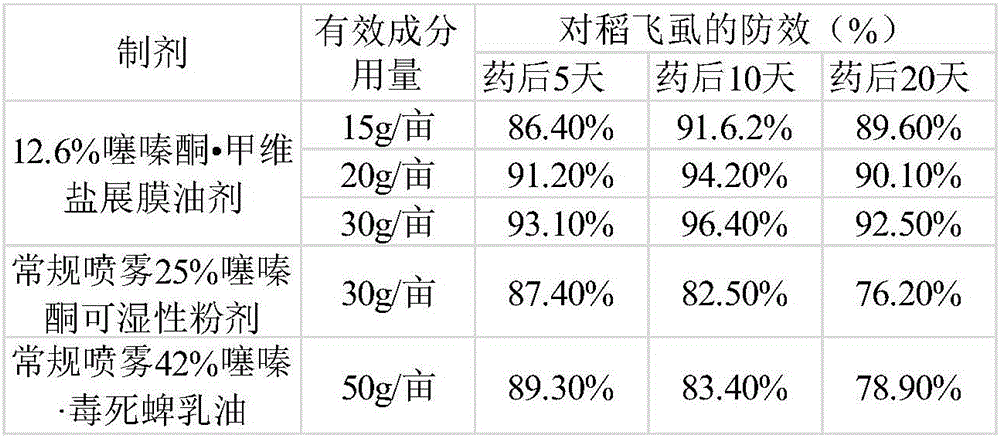

[0042] Among the present invention, 12.6% buprofezin emamectin film spreading oil agent and conventional spraying are as shown in table 3 to the control effect of rice planthopper:

[0043] table 3

[0044]

[0045] It can be seen from Table 3 that the control effect on rice planthopper after application o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com