Determination method of thermal-deformation microstructure evolution mechanisms and thermal machining performance of C-Mn-Al high-strength steel

A determination method, c-mn-al technology, applied in geometric CAD, special data processing applications, instruments, etc., can solve the problems that the accuracy needs to be further improved

Inactive Publication Date: 2018-09-28

ANHUI UNIVERSITY OF TECHNOLOGY

View PDF7 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the application still uses the traditional hyperbolic sine constitutive model, and the accuracy of its prediction results still needs to be further improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0040] A kind of C-Mn-Al high-strength steel hot-deformed microstructure evolution mechanism and the determination method of hot-working performance of the present embodiment, the method comprises the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

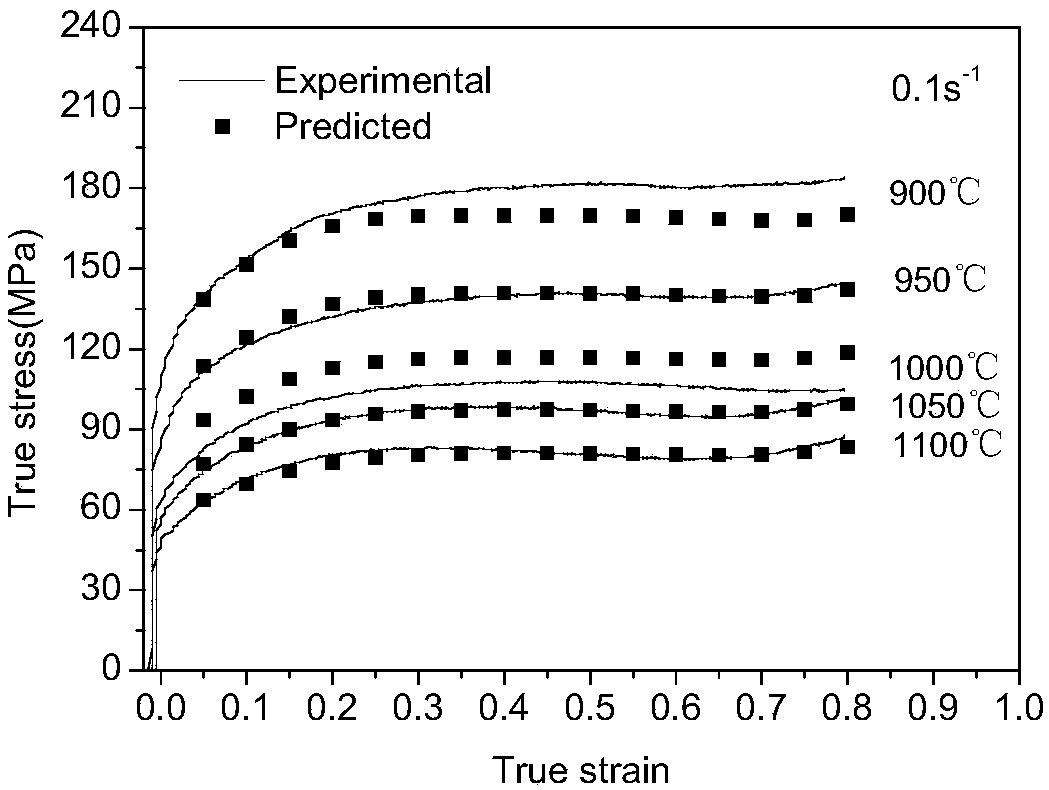

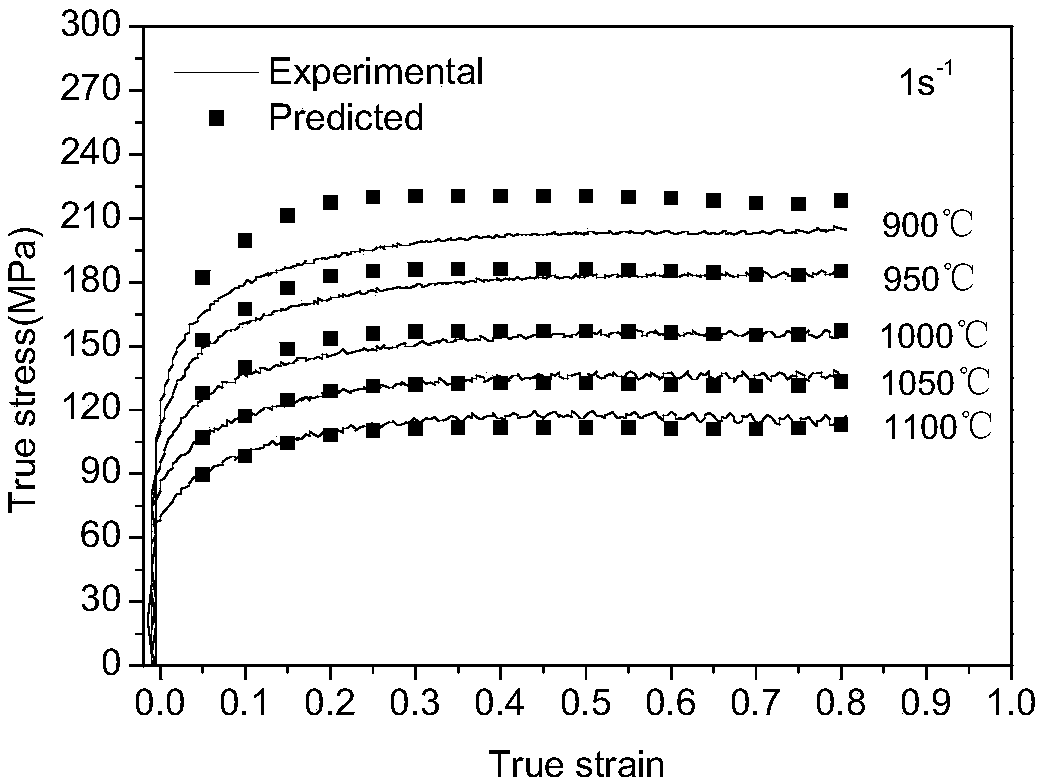

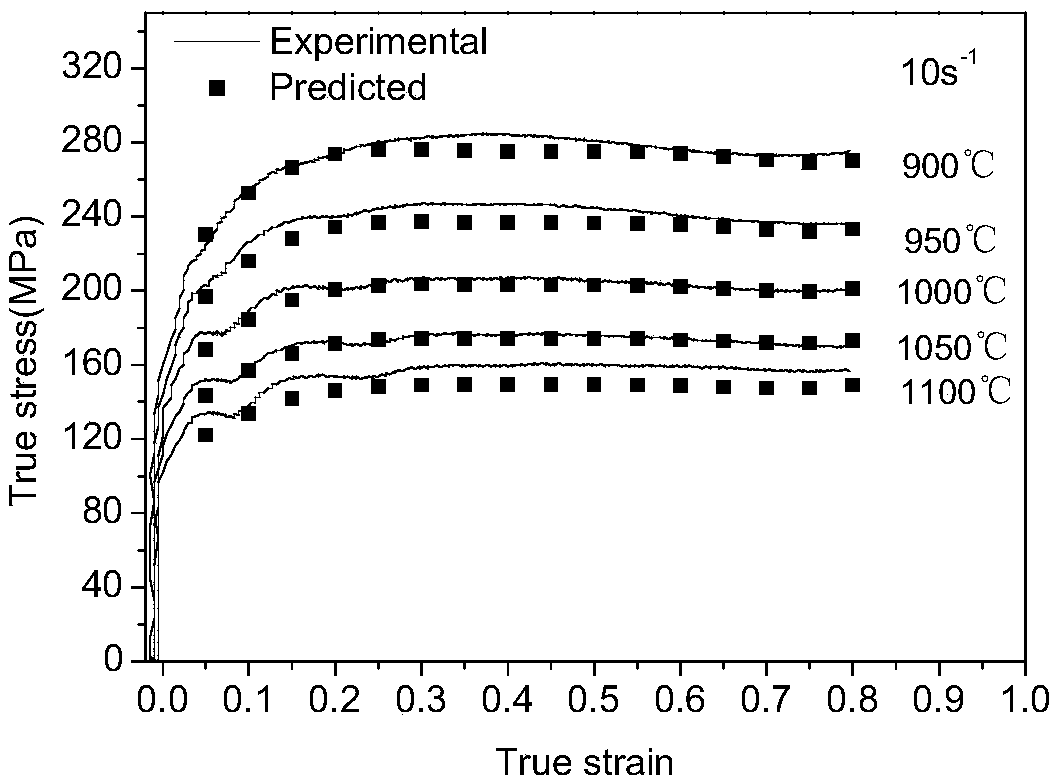

The invention belongs to the technical field of high-strength steel machining engineering, and particularly relates to a determination method of thermal-deformation microstructure evolution mechanismsand thermal machining performance of C-Mn-Al high-strength steel. According to the method, firstly, a high-temperature compression test is carried out on the novel C-Mn-Al high-strength steel, and true stress-true strain curve data of the steel are obtained; then a rheology stress prediction model of the steel is established, model selection is based on creep theory, a class of constitutive models which are of relationships of Young's modulus and a self-diffusion coefficient of austenite and temperature and have physics bases are considered, and the established constitutive model can accurately predict rheology stress of the steel; a thermal-deformation machining graph of the steel is established, and microstructures are combined to determine the microstructure evolution mechanisms of different regions in the machining graph. The constitutive model of thermal deformation and the machining graph are combined, the thermal-deformation rheology stress and thermal-deformation power dissipation efficiency under arbitrary deformation conditions are analyzed, thus the corresponding microstructure evolution mechanisms and thermal machining performance information are obtained, and resultshave great significance for thermal machining process control of the high-strength steel.

Description

technical field [0001] The invention belongs to the technical field of high-strength steel processing engineering, and particularly relates to a method for determining the thermal deformation microstructure evolution mechanism and thermal processing performance of C-Mn-Al high-strength steel. Background technique [0002] In order to save energy and protect the environment, it is urgent to develop high-strength steels with good ductility and toughness, including TRIP steels. Conventional TRIP steels were developed based on the C-Mn-Si alloy system. The purpose of using high silicon content is to suppress the formation of cementite during cooling so as to increase the stability and quantity of retained austenite. However, high silicon content may cause steel defects such as hard oxide layer, poor surface properties and low coating ability. Since the substitution of Al for Si can eliminate these harmful effects of Si, C-Mn-Al-Si or C-Mn-Al-based TRIP steels have attracted mor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F17/50

CPCG06F30/17G06F30/20

Inventor 魏海莲潘红波周红伟邓贤波

Owner ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com