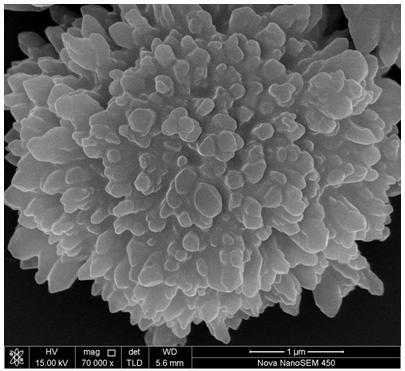

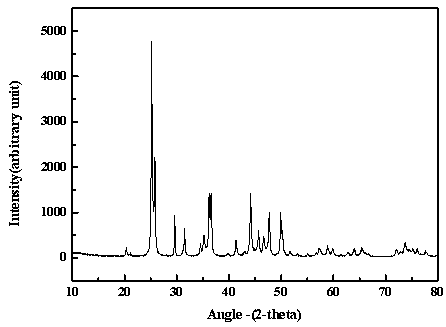

Method and device for preparing strontium carbonate crystals through self-diffusion at room temperature

A strontium carbonate, self-diffusion technology, applied in the direction of strontium carbonate, calcium carbonate/strontium/barium, etc., can solve the problems of uncontrollable reaction, complicated operation, high energy consumption, etc., and achieve low production cost, high preparation efficiency, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

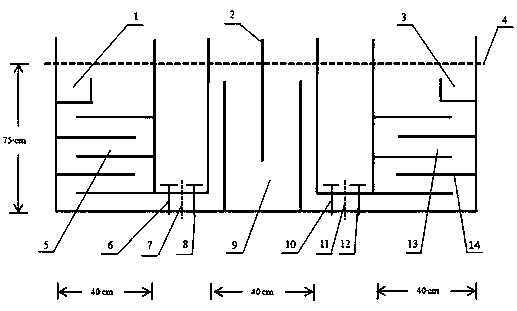

[0016] In the reaction device, 0.60 kg of strontium dichloride hexahydrate was added to the No. 1 material tank (1) of the No. 1 reactor (5), and 0.64 kg of ammonium bicarbonate was added to the No. 2 reactor of the No. 3 reactor (13). In the No. material tank (3), open the No. 1 valve (6), No. 2 valve (8), No. 3 valve (10) and No. 4 valve (12) in the reaction device, and feed from No. 2 reactor (9) 0.020% glycine solution to the water level mark (4), at room temperature, let stand for reaction for 24 hours. Add 0.60 kg of strontium dichloride hexahydrate into No. 1 material tank (1) of No. 1 reactor (5), and 0.64 kg of ammonium bicarbonate into No. 2 material tank (3) of No. 3 reactor (13) , at room temperature for 24 h. Add 0.60 kg of strontium dichloride hexahydrate into No. 1 material tank (1) of No. 1 reactor (5), and 0.64 kg of ammonium bicarbonate into No. 2 material tank (3) of No. 3 reactor (13) , at room temperature, after standing for 48 hours to react, close the ...

Embodiment 2

[0019] In the reaction device, 0.60 kg of strontium dichloride hexahydrate was added to No. 1 material tank (1) of No. 1 reactor (5), and 0.62 kg of ammonium bicarbonate was added to No. 2 of No. 3 reactor (13). In the material tank (3), open the No. 1 valve (6), No. 2 valve (8), No. 3 valve (10) and No. 4 valve (12) in the reaction device, and add 0.020 % glycine solution to the water level mark (4), at room temperature, let stand for reaction for 24 h. Add 0.60 kg of strontium dichloride hexahydrate into No. 1 material tank (1) of No. 1 reactor (5), and 0.62 kg of ammonium bicarbonate into No. 2 material tank (3) of No. 3 reactor (13) , at room temperature for 24 h. Add 0.60 kg of strontium dichloride hexahydrate into No. 1 material tank (1) of No. 1 reactor (5), and 0.62 kg of ammonium bicarbonate into No. 2 material tank (3) of No. 3 reactor (13) , at room temperature, after standing for 48 hours to react, close the four valves, disassemble the No. 1 disassembly station ...

Embodiment 3

[0022] In the reaction device, 0.60 kg of strontium dichloride hexahydrate was added to No. 1 material tank (1) of No. 1 reactor (5), and 0.66 kg of ammonium bicarbonate was added to No. 2 of No. 3 reactor (13). In the material tank (3), open the No. 1 valve (6), No. 2 valve (8), No. 3 valve (10) and No. 4 valve (12) in the reaction device, and add 0.020 % glycine solution to the water level mark (4), at room temperature, let stand for reaction for 24 h. Add 0.60 kg of strontium dichloride hexahydrate into No. 1 material tank (1) of No. 1 reactor (5), and 0.66 kg of ammonium bicarbonate into No. 2 material tank (3) of No. 3 reactor (13) , at room temperature for 24 h. Add 0.60 kg of strontium dichloride hexahydrate into No. 1 material tank (1) of No. 1 reactor (5), and 0.66 kg of ammonium bicarbonate into No. 2 material tank (3) of No. 3 reactor (13) , at room temperature, after standing for 48 hours to react, close the four valves, disassemble the No. 1 disassembly station ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com