Method for preparing Si3N4 gradient material through self-diffusion

A gradient material and self-diffusion technology, which is applied in the field of non-oxide ceramic matrix composite materials, can solve the problems of insufficient bonding force between the matrix and the conductive layer, detachment of the surface layer from the core, and weak bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

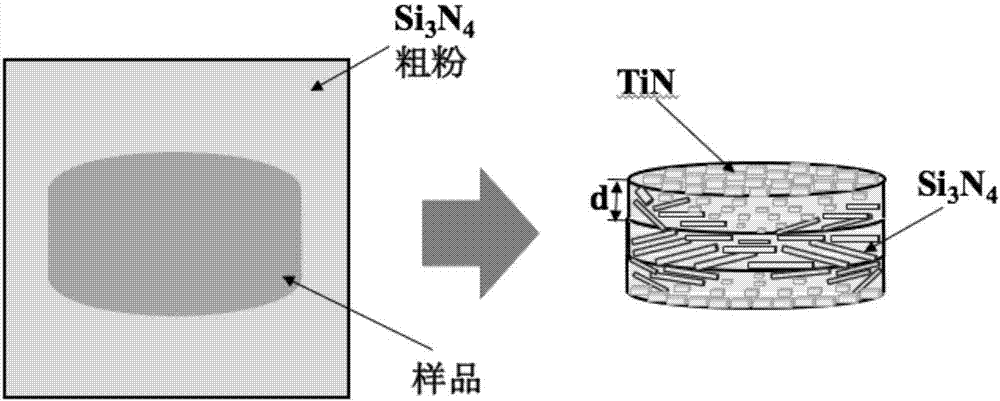

[0028] A preparation of Si by self-diffusion 3 N 4 The specific method of gradient material is as follows:

[0029] (1) with Si 3 N 4 and ZrO 2 Powder as raw material, with MgO and Y 2 o 3 As a sintering aid, according to Si 3 N 4 : ZrO 2 : MgO-Re 2 o 3 The mass fraction ratio is 70%:20%:10%, the MgO-Re 2 o 3 MgO in: Re 2 o 3 The mass fraction ratio is 55%: 45%; with ethanol as solvent and Si 3 N 4 The ball is the ball milling medium, mixed on a roller ball mill for 24 hours, after mixing and drying, a uniformly mixed Si-ZrO 2 -MgO-Y 2 o 3 Mix powder.

[0030] (2) Si-ZrO 2 -MgO-Y 2 o 3 The mixed powder is put into a mold for cold isostatic pressing molding, the cold isostatic pressing molding pressure is 200MPa, and the holding time is 5min.

[0031] (3) Si-ZrO 2 -MgO-Y 2O 3 The green body is embedded in Si 3 N 4 The powder is put into a boron nitride crucible, the temperature is raised to 1400°C for 2 hours at a heating rate of 20°C / min, and then t...

Embodiment 2

[0034] According to Si 3 N 4 : ZrO 2 : MgO-Re 2 O 3 The mass fraction ratio is 50%: 40%: 10% for batching, in which MgO: Yb 2 O 3 The mass fraction ratio is 60%: 40%, and Si is prepared according to the method of Example 1 3 N 4 Ceramics, in which the temperature is first heated to 1375 °C for 24 hours, then heated to 1900 °C for 12 hours, and sintered at a pressure of 10 MPa, and the sintering atmosphere is nitrogen. The relative density of the prepared ceramic material is 99%, the hardness of the material is 25GPa, and the fracture toughness is 14MPa m 1 / 2 , the flexural strength is 1500Mpa, and the gradient layer thickness is 100μm.

Embodiment 3

[0036] According to Si 3 N 4 : TiO 2 : MgO-Gd 2 O 3 The mass fraction ratio is 72%: 20%: 8% for batching, in which MgO: Gd 2 O 3 The mass fraction ratio is 60%: 40%, and Si is prepared according to the method of Example 1 3 N 4 Ceramics, in which the temperature is first heated to 1375 °C for 4 hours, and then heated to 1900 °C for 4 hours, and sintered at a pressure of 10 MPa, and the sintering atmosphere is nitrogen. The relative density of the prepared ceramic material is 99%, the hardness of the material is 20GPa, and the fracture toughness is 14MPa m 1 / 2 , the flexural strength is 1200Mpa, and the gradient layer thickness is 80μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com