Preparation method of ordered mesoporous carbon material

A mesoporous carbon and reactor technology, which is applied in the field of mesoporous carbon materials, can solve the problems of increased operating costs, difficult separation of paste and mechanical equipment, and increased equipment investment, so as to reduce investment costs and achieve good mesoscopic order. The effect of reducing the cost of post-operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

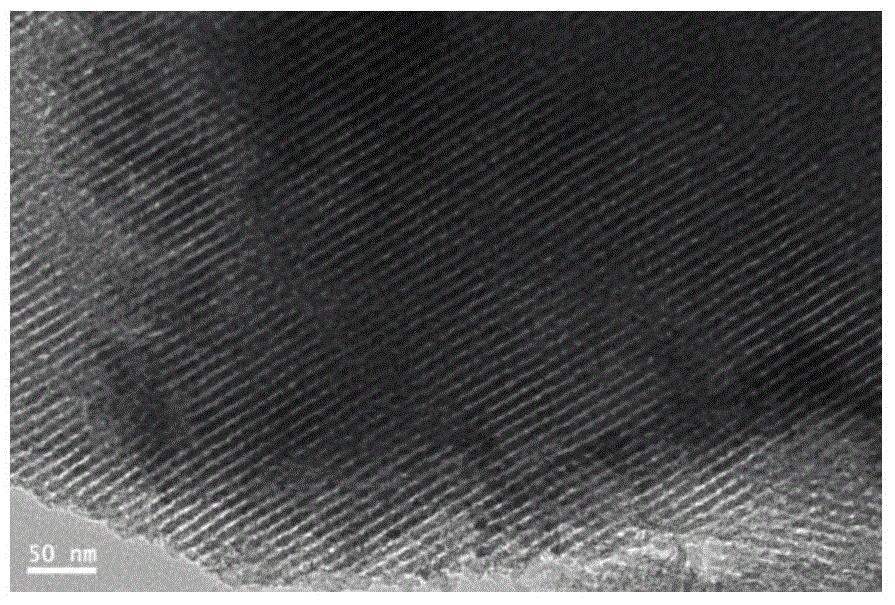

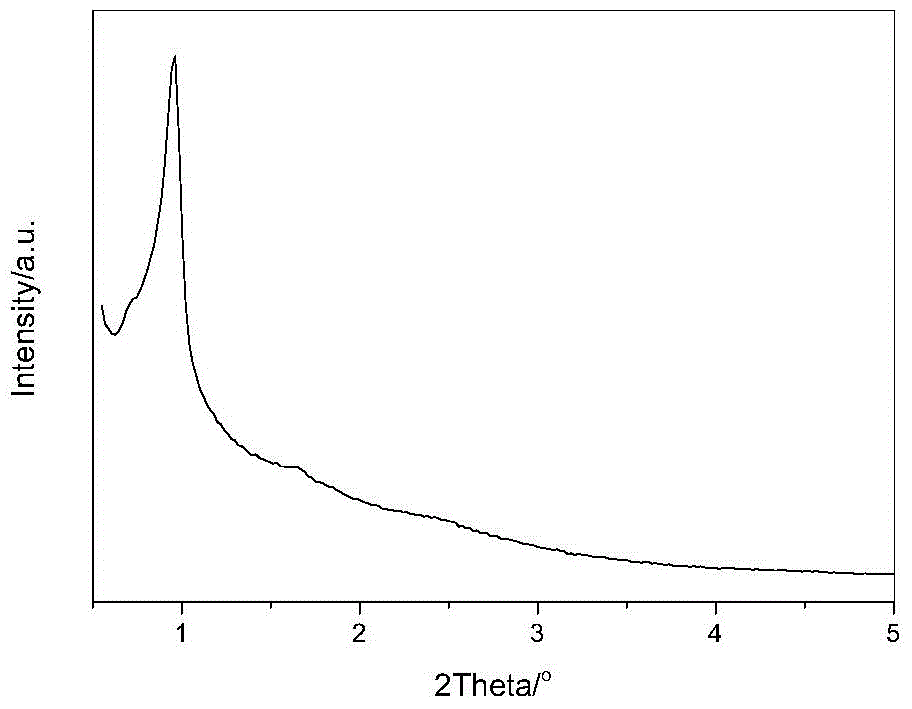

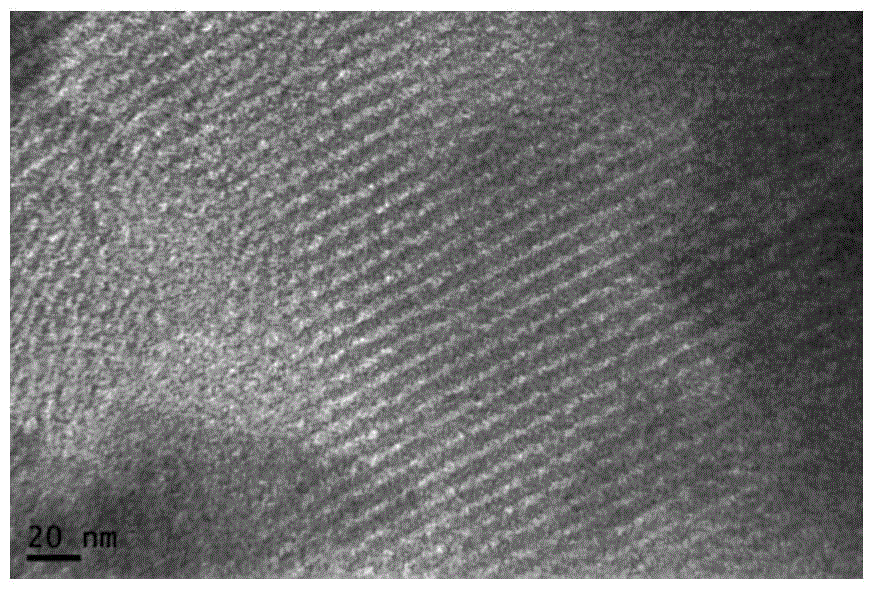

[0024] Simply mix 1.0 gram of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer F127, 0.21 gram of resorcinol and 0.32 gram of terephthalaldehyde in a closed reaction kettle, Then heat-treat in an oven at 80°C for 120 minutes, then place the obtained bulk composite material in a muffle furnace, and bake at 800°C for 120 minutes under an inert atmosphere, and finally obtain an ordered mesoporous carbon material. The TEM and XRD patterns of the mesoporous carbon material are as follows figure 1 , 2 It can be seen from the figure that the mesoporous carbon has very good mesoscopic order, and the order of pores is very high.

Embodiment 2

[0026] 2.0 grams of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer F127, 0.21 grams of resorcinol and 0.32 grams of terephthalaldehyde were simply mixed and placed in a closed reaction kettle. Then heat-treat in an oven at 300°C for 60 minutes, then place the obtained bulk composite material in a muffle furnace, and bake at 500°C for 300 minutes under an inert atmosphere, and finally obtain an ordered mesoporous carbon material.

Embodiment 3

[0028] 3.0 grams of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer F127, 0.21 grams of resorcinol and 1.12 grams of terephthalaldehyde were simply mixed and placed in a closed reaction kettle. Then heat-treat in an oven at 100°C for 240 minutes, then place the obtained bulk composite material in a muffle furnace, and bake at 400°C for 420 minutes under an inert atmosphere, and finally obtain an ordered mesoporous carbon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com