Method for preparing electronic high temperature superconductor lanthanum-cerium-copper oxide films

A superconductor and electronic technology, applied in the manufacture/processing of superconductor devices, ion implantation plating, coating, etc., can solve the problems of slow film deposition rate and expensive equipment, achieve a large practical range and value, and grow at a low temperature , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The specific preparation steps of this embodiment are as follows:

[0039] 1. According to La 2-x Ce x CuO 4 Proportional weighing, wherein x=0.10, the LCCO ceramic target is made by the solid phase reaction method, and installed on the target base of the reaction chamber; this embodiment adopts the solid phase reaction method

[0040] The specific steps of preparing LCCO ceramic targets by traditional solid state reaction sintering method are as follows:

[0041] a. Ingredients: Calculate the chemical ratio of the target material according to x=0.10, weigh a certain amount of high-purity (>99.9%) La2O3, CeO2 and CuO powders, put them in an agate mortar and grind them evenly;

[0042] b. Pre-calcination: first pre-calcine the mixture at 800-900°C for 12-24 hours, so that various raw materials can undergo preliminary synthesis reactions. Then cool down and take out to grind evenly. Sinter the pre-fired powder at a high temperature of 950°C for more than 48 hours to ...

Embodiment 2

[0055] In this embodiment, the substrate is selected from MgO, and over-doped La 2-x Ce x CuO 4 The target, where x=0.08, the growth temperature is 675°C, the gas in the reaction chamber is oxygen, the pressure in the reaction chamber is 10Pa, the distance between the target and the base is adjusted to 3cm, the laser pulse frequency is 3Hz during growth, the pulse energy is 180mJ, and the deposition time is 10 minutes, the annealing temperature is 450° C. and the annealing time is 10 minutes. Other steps and parameters are the same as in Example 1. The superconducting transition temperature of the LCCO film sample prepared in this example is 5.0K.

Embodiment 3

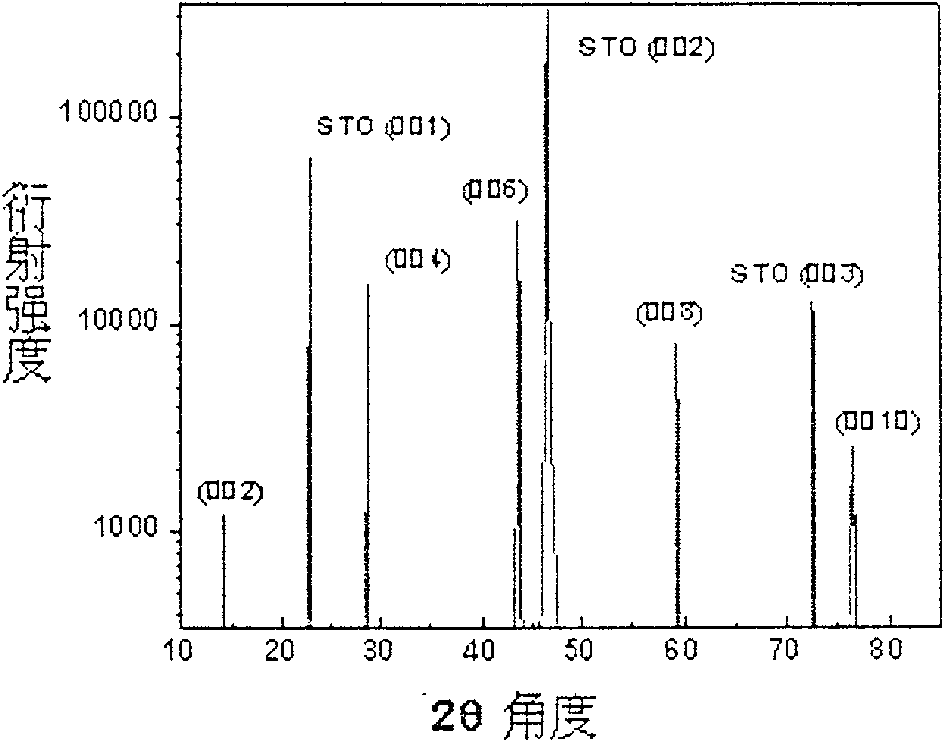

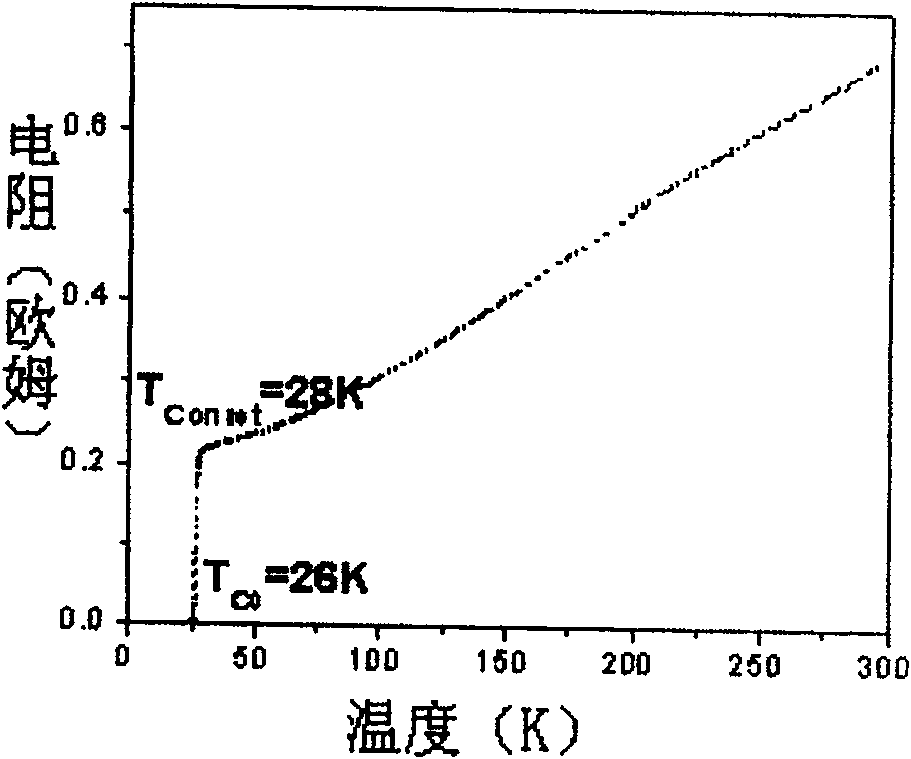

[0057] In this embodiment, the substrate is selected from LaAlO 3 , and select overdoped La 2-x Ce x CuO 4 The target, where x=0.11, the growth temperature is 720°C, the gas in the reaction chamber is oxygen, the pressure in the reaction chamber is 20Pa, the distance between the target and the base is adjusted to 4cm, the laser pulse frequency is 4Hz during growth, the pulse energy is 220mJ, and the deposition time is 15 Minutes, the annealing temperature is 550 ℃ of annealing time 15 minutes, other steps and parameters are identical with embodiment 1, measure the resistance-temperature curve of the LCCO thin film sample that present embodiment prepares, as image 3 As shown, the initial superconducting transition temperature of the sample is 28K, when the temperature drops to the zero resistance transition temperature T C0 At 26K, it is completely superconducting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com