Superconducting magnet

A superconducting magnet and superconducting technology, applied in the direction of superconducting magnets/coils, magnetic objects, electrical components, etc., can solve the difficulties of manufacturing process, limit large-scale application, and the performance of superconducting joints cannot meet the requirements of practical applications. , to achieve high superconducting stability, not easy to quench, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

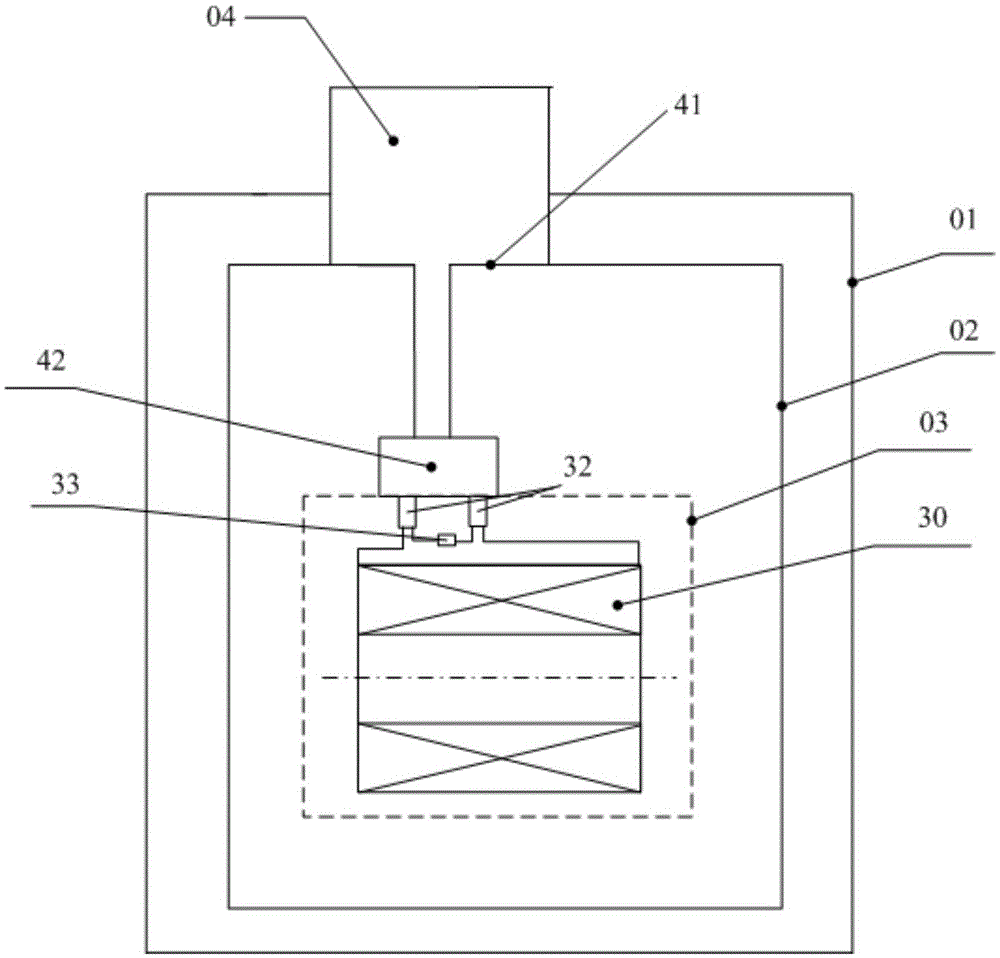

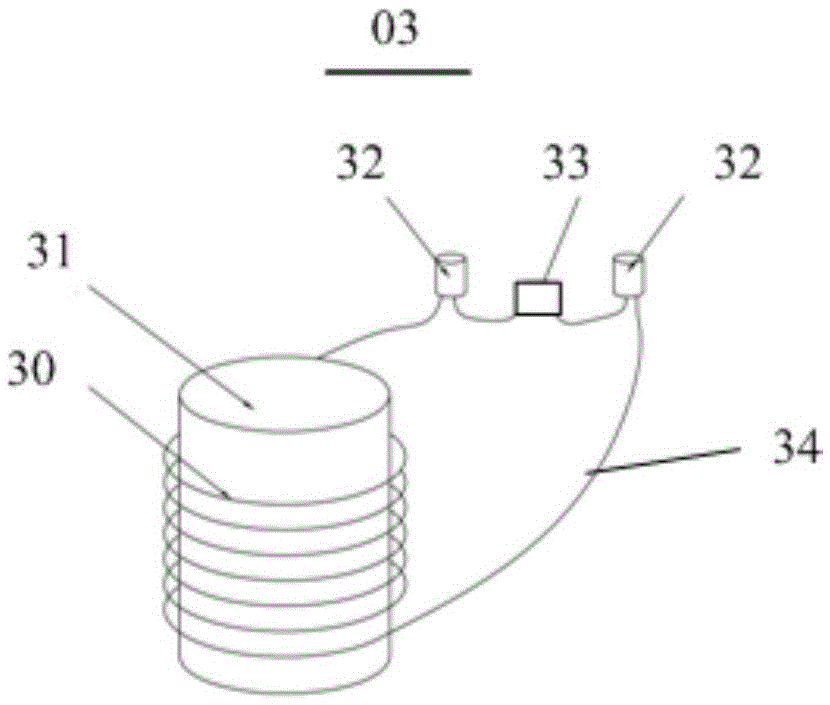

[0033] figure 1 It is a structural schematic diagram of a superconducting magnet provided by an embodiment of the present invention. Such as figure 1 As shown, the superconducting magnet includes: a vacuum container 01 , in which a cold shield 02 and a superconducting coil 30 are arranged, wherein the superconducting coil 30 is located inside the cold shield 02 .

[0034] The function of the cold shield 02 is to reduce radiation heat leakage from room temperature to the superconducting coil 30 .

[0035] In the embodiment of the present invention, the material of the vacuum container 01 may be stainless steel, of course, other non-magnetic materials other than stainless steel may also be used. In addition, the vacuum vessel 01 can be manufactured according to the relevant pressure vessel standards of our country, so that the failure of the vacuum vessel 01 can be effectively avoided and the normal operation of the superconducting magnet can be ensured.

[0036] In addition,...

Embodiment 2

[0049] It should be noted that the superconducting magnet described in Embodiment 2 has many similarities with the superconducting magnet described in Embodiment 1. For the sake of brevity, this embodiment of the present invention only describes the differences in detail. The similarities Please refer to the relevant description of Embodiment 1.

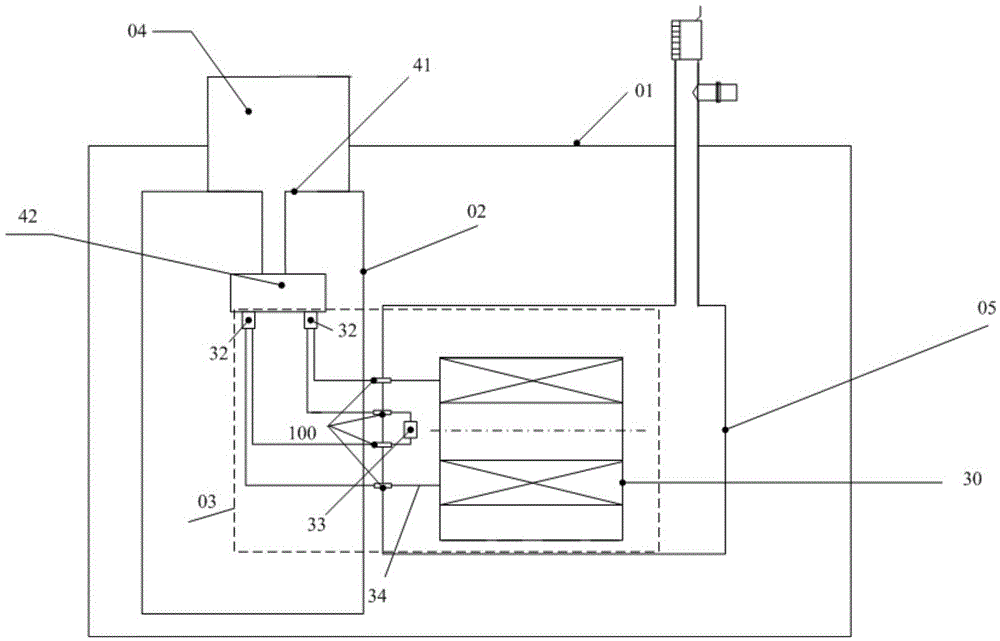

[0050] image 3 It is a schematic structural diagram of the superconducting magnet provided by Embodiment 2 of the present invention. Such as image 3 As shown, the superconducting magnet includes: a vacuum container 01 , a cold shield 02 , a superconducting coil 30 and a refrigerator 04 . In addition, the superconducting magnet may also include a liquid nitrogen container 05 . Wherein, the liquid nitrogen container 05 is arranged inside the vacuum container 01 and outside the cold shield 02 , and the liquid nitrogen submerged in the superconducting coil 30 is contained in the liquid nitrogen container 05 .

[0051] In the embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Superconducting transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com