Method for improving FeSe superconducting transition temperature by adding Mg

A transition temperature, superconducting technology, applied in the field of superconductivity, to achieve the effect of increasing the superconducting transition temperature, simple and easy technology, and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

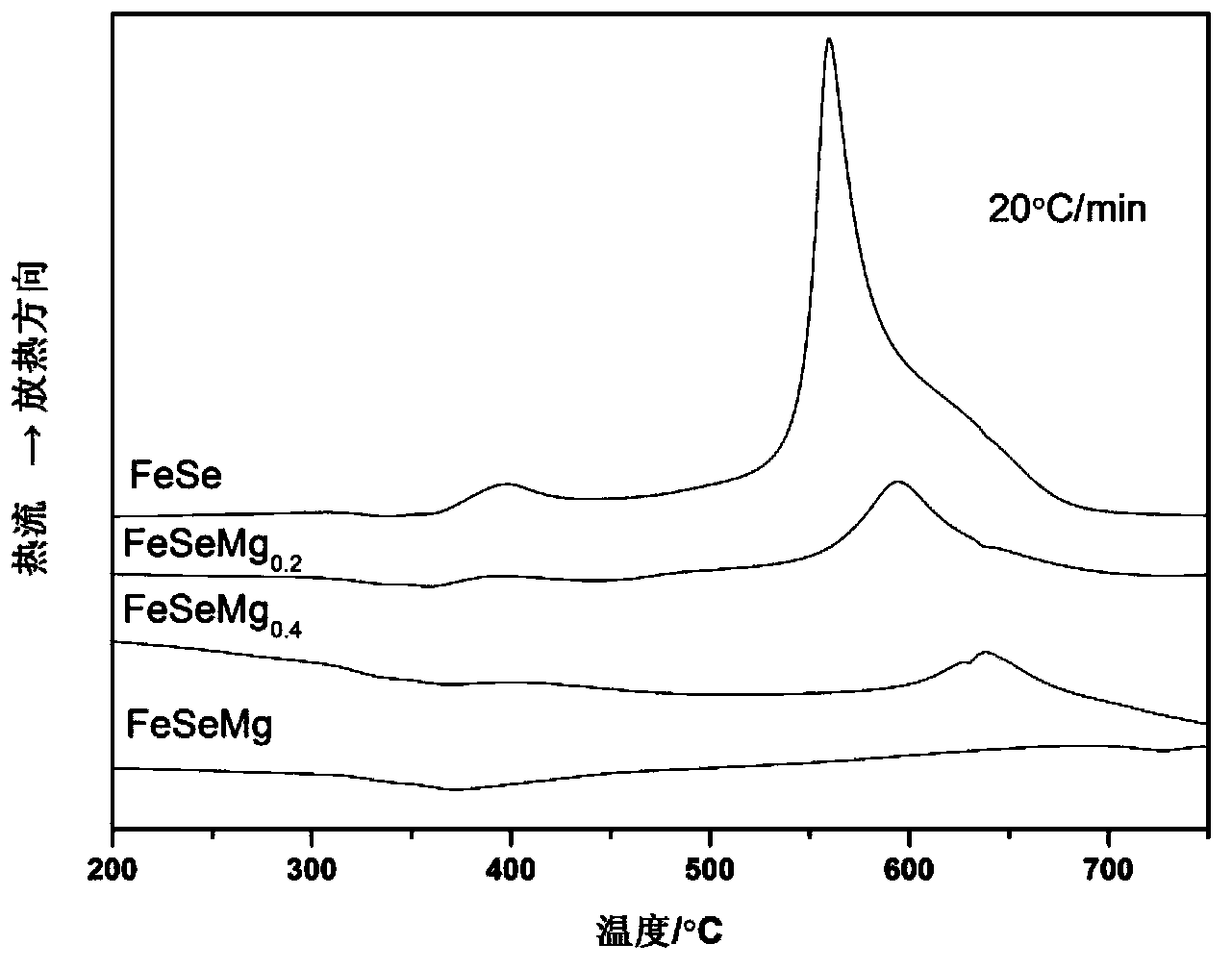

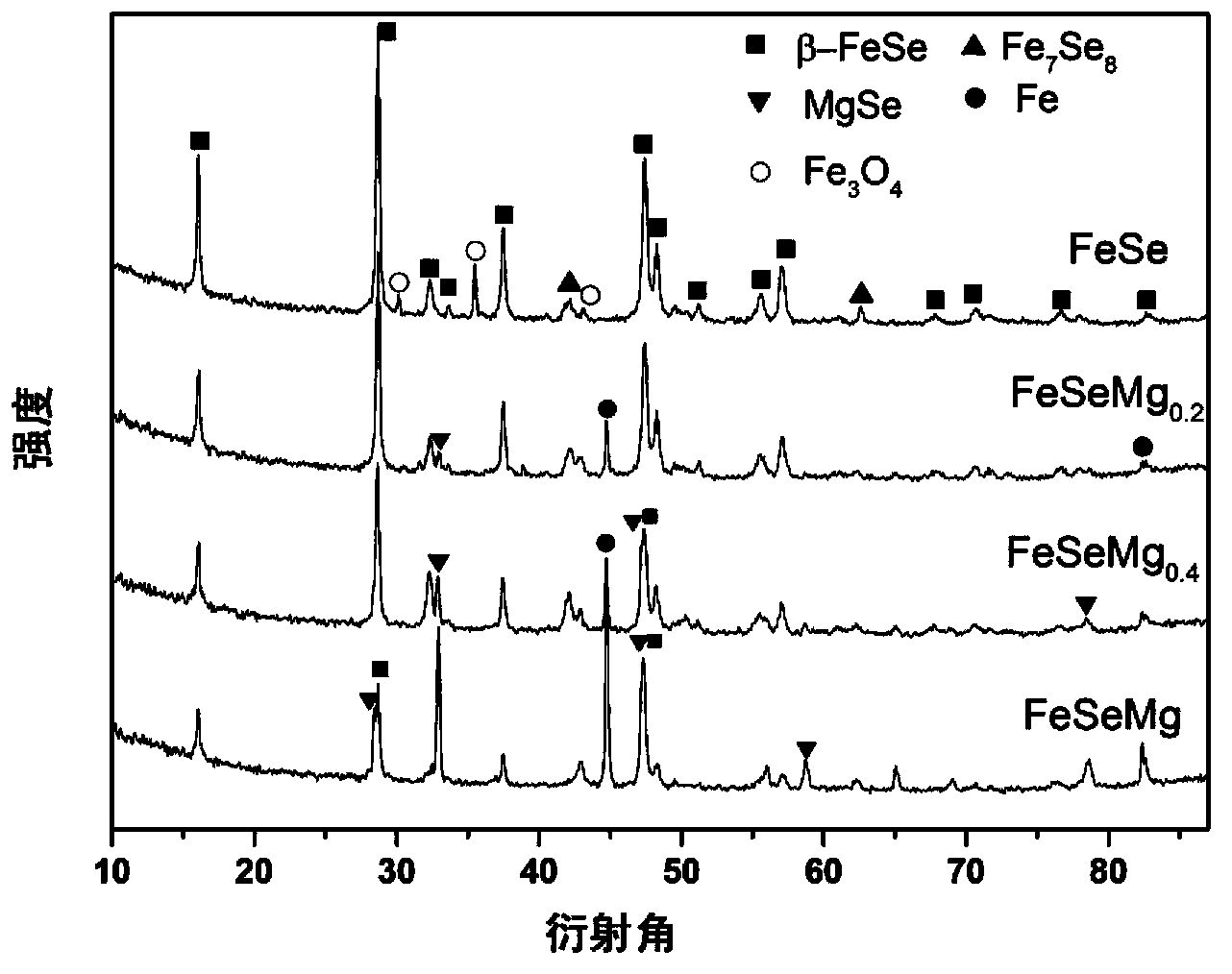

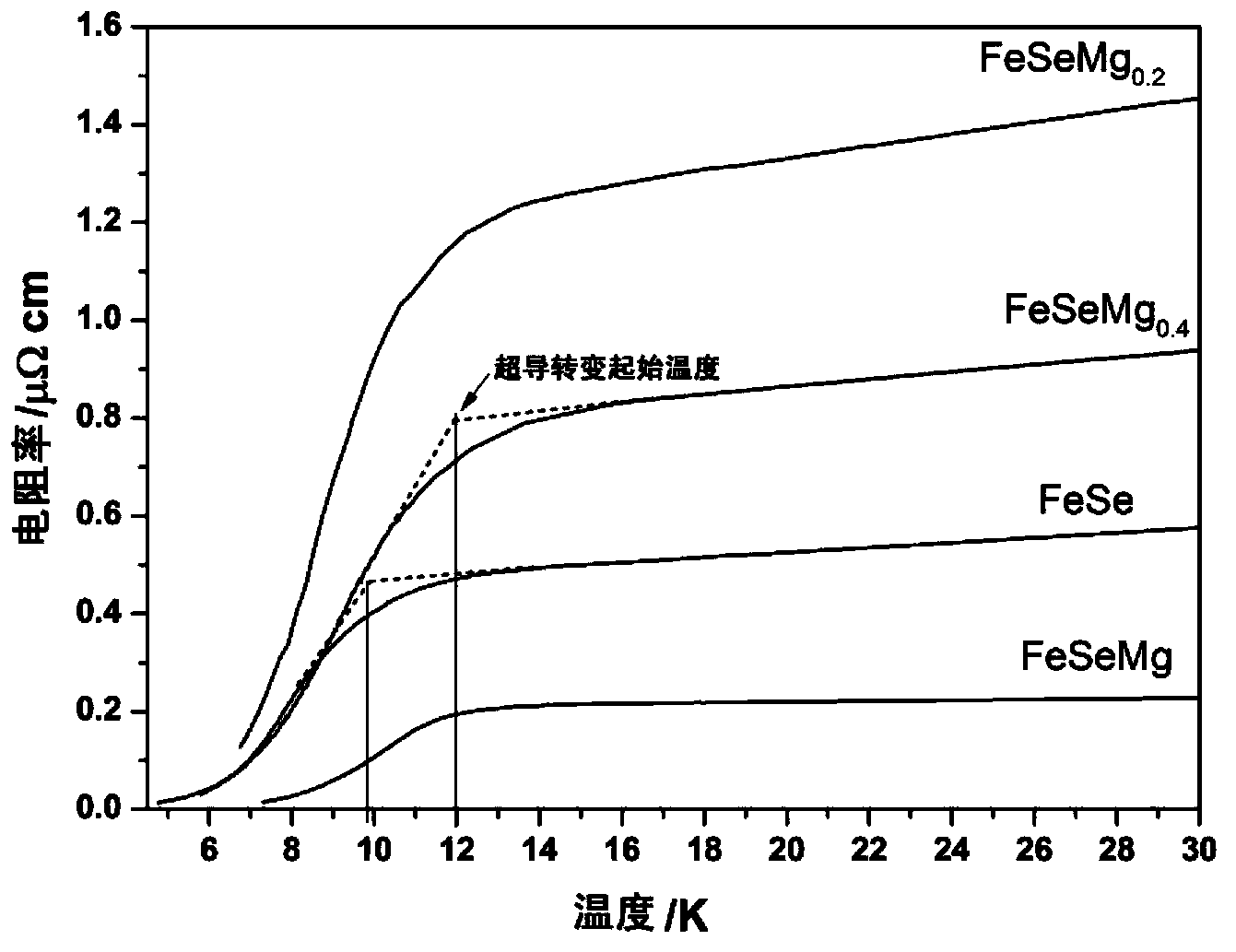

[0018] Mix and grind Fe powder and Se powder in an agate mortar or planetary ball mill for 30 minutes according to the atomic ratio of Fe:Se=1:0.90, then make flakes under a pressure of 5MPa, and finally put the flakes into high temperature difference Scanning calorimeter or tubular sintering furnace for argon protection atmosphere sintering, the heating rate is 20°C / min. room temperature.

[0019] The sintered FeSe block was taken out and ground into powder again. Then Mg powder and FeSe powder were mixed according to the atomic ratio of 0.4:1, and thoroughly ground for 30 minutes in an agate mortar or planetary ball mill. Then make thin slices under a pressure of 5MPa, and finally put the thin slices into a high-temperature differential scanning calorimeter, and under the protection of flowing high-purity argon, heat up to 750°C at a rate of 20°C / min. Keep warm for 0.5 hours, then cool down to room temperature at a cooling rate of 40°C / min, and take out the sintered sample...

Embodiment 2

[0022] Mix and grind Fe powder and Se powder in an agate mortar or planetary ball mill for 60 minutes according to the atomic ratio of Fe:Se=1:1, then make thin slices under a pressure of 10MPa, and finally put the thin slices into high temperature difference Scanning calorimeter or tubular sintering furnace for argon protection atmosphere sintering, the heating rate is 40°C / min, after rising to 700°C, keep sintering at this temperature for 18 hours, and then cool down to room temperature.

[0023] The sintered FeSe block was taken out and ground into powder again. Then Mg powder and FeSe powder were mixed according to the atomic ratio of 0.2:1, and fully ground in an agate mortar or planetary ball mill for 60 minutes. Then make thin slices under a pressure of 10MPa, and finally put the thin slices into a high-temperature differential scanning calorimeter. Keep warm for 0.5 hours, then cool down to room temperature at a cooling rate of 40°C / min, and take out the sintered sam...

Embodiment 3

[0026] Mix and grind Fe powder and Se powder in an agate mortar or planetary ball mill for 20 minutes according to the atomic ratio of Fe:Se=1:1.05, then make flakes under a pressure of 2MPa, and finally put the flakes into high temperature difference Scanning calorimeter or tubular sintering furnace for argon protective atmosphere sintering, heating rate 10 ℃ / min, after rising to 600 ℃, keep sintering at this temperature for 48 hours, and then cool down to 10 ℃ / min room temperature.

[0027] The sintered FeSe block was taken out and ground into powder again. Then Mg powder and FeSe powder were mixed according to the atomic ratio of 1:1, and fully ground in an agate mortar or planetary ball mill for 20 minutes. Then make thin slices under a pressure of 2MPa, and finally put the thin slices into a high-temperature differential scanning calorimeter. Keep warm for 1 hour, then cool down to room temperature at a cooling rate of 10°C / min, and take out the sintered sample.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com