Preparation of boron doped diamond superconduction material

A technology of superconducting materials and diamond, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem that the superconducting transition temperature of diamond film is not high enough, the film forming area is difficult to expand, and the effective doping concentration is not high enough. Advanced problems, to achieve the effect of inhibiting the loss of active boron atoms, simple structure, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

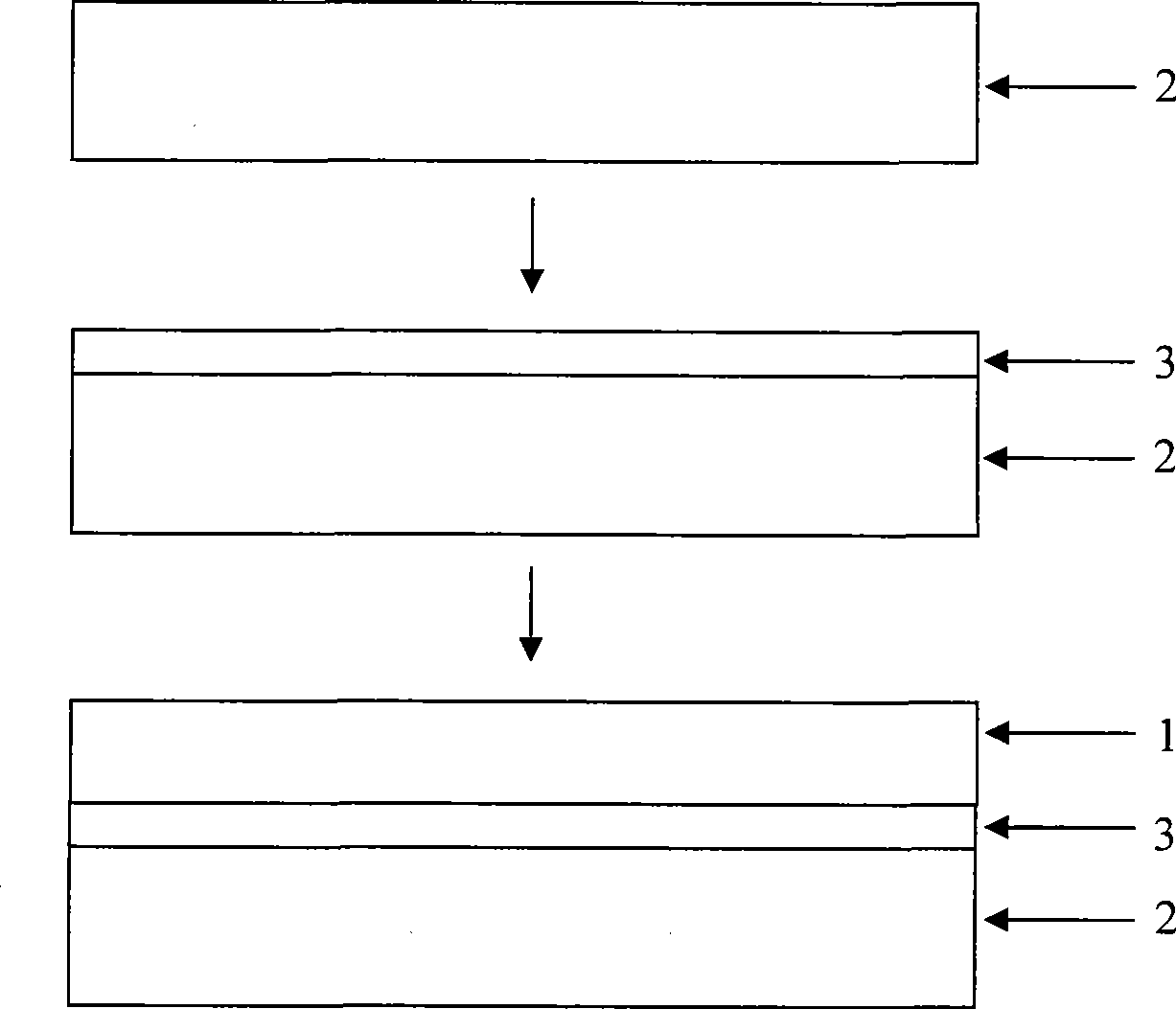

[0034] refer to image 3 , carried out in a hot filament chemical vapor deposition system, the method of the present invention is described in detail through the following specific steps.

[0035] 1. First, pretreat the inner wall of the cavity of the hot filament chemical vapor deposition system by hot filament chemical vapor deposition of boron-doped diamond film. Pretreatment conditions: the flow rates of methane and hydrogen are 8 sccm and 100 sccm respectively At the same time, the hydrogen gas with a flow rate of 10 sccm is introduced, and the hydrogen gas enters the cavity of the deposition system after passing through the container containing trimethyl borate—hereinafter referred to as "hydrogen gas carrying trimethyl borate", that is, the flow rate of hydrogen gas carrying trimethyl borate is 10sccm, the reaction pressure in the cavity is 25 Torr, the filament temperature is about 2200°C, and the pretreatment is carried out for 10 hours; under the above conditions, th...

Embodiment 2

[0042] refer to image 3 , the method of the present invention is described in detail through the following specific steps.

[0043] 1. First, the inner wall of the cavity of the hot filament chemical vapor deposition system is pretreated by the method of hot filament chemical vapor deposition of a boron-doped diamond film, and the remaining pretreatment conditions and pretreatment time are completely the same as in Example 1;

[0044] 2. With a polished N-type (001) single crystal silicon wafer as the substrate, take an alcohol solution in which diamond powder with a particle size of 0.2 microns is dissolved, put the single crystal silicon into the solution and perform ultrasonication for 60 minutes, and the silicon substrate Diamond nucleation points are generated on the bottom, and then the cleaning process for semiconductor material preparation is carried out, such as cleaning with cleaning solutions such as acetone, ethanol or deionized water;

[0045] 3. Deposit diamond...

Embodiment 3

[0049] refer to image 3 , the method of the present invention is described in detail through the following specific steps.

[0050] 1. First, pretreat the inner wall of the cavity of the hot filament chemical vapor deposition system by hot filament chemical vapor deposition of boron-doped diamond film. Pretreatment conditions: the flow rates of methane and hydrogen are 8 sccm and 100 sccm respectively At the same time, the flow rate of hydrogen carrying trimethyl borate is 6 sccm, the reaction pressure in the chamber is 40 Torr, the temperature of the filament is about 2200 ° C, and the pretreatment is carried out for 25 hours;

[0051] 2. With a polished N-type (001) single crystal silicon wafer as the substrate, take an alcohol solution in which diamond powder with a particle size of 0.2 microns is dissolved, put the single crystal silicon into the solution and perform ultrasonication for 60 minutes, and the silicon substrate Diamond nucleation points are produced on the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com