Method for preparing iron selenium superconducting material by spark plasma sintering technology

A technology for discharging plasma and superconducting materials, which is applied in the field of preparing iron-selenium superconducting materials by ion sintering technology, can solve the problems of complicated synthesis steps, long preparation time, unfavorable large-scale preparation of superconducting FeSe materials and the like, and achieves the preparation method. Simple and fast, promote the formation of superconducting phase, and achieve the effect of large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

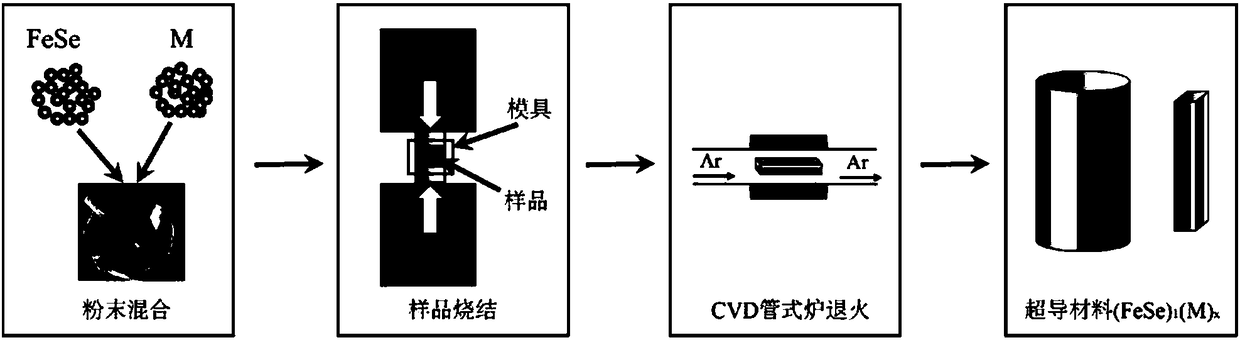

[0040] Such as figure 1 As shown, the specific preparation method of the superconducting iron selenium material of the present invention comprises the following steps:

[0041] (1) According to the molar ratio of 1:x, weigh 5.0g iron selenium and insulator M powder with a total weight, put them in a grinding bowl, and grind for 30 minutes to ensure that the two powders are fully mixed and evenly dispersed; the value range of x is 0.2~ 15.

[0042] (2) Conduct discharge plasma sintering on the ground powder sample: first, put the powder sample into a graphite mold with a diameter of 12.7 mm and a height of 30 mm for compaction, then wrap a layer of carbon felt on the outside of the mold, and finally put the mold into spark plasma sintering furnace. Increase the pressure to 30MPa, evacuate until the vacuum degree is less than 5Pa, and start to apply current to raise the temperature and sinter. Keep the heating rate at 50K / min~100K / min as much as possible, after about 30min th...

Embodiment 1

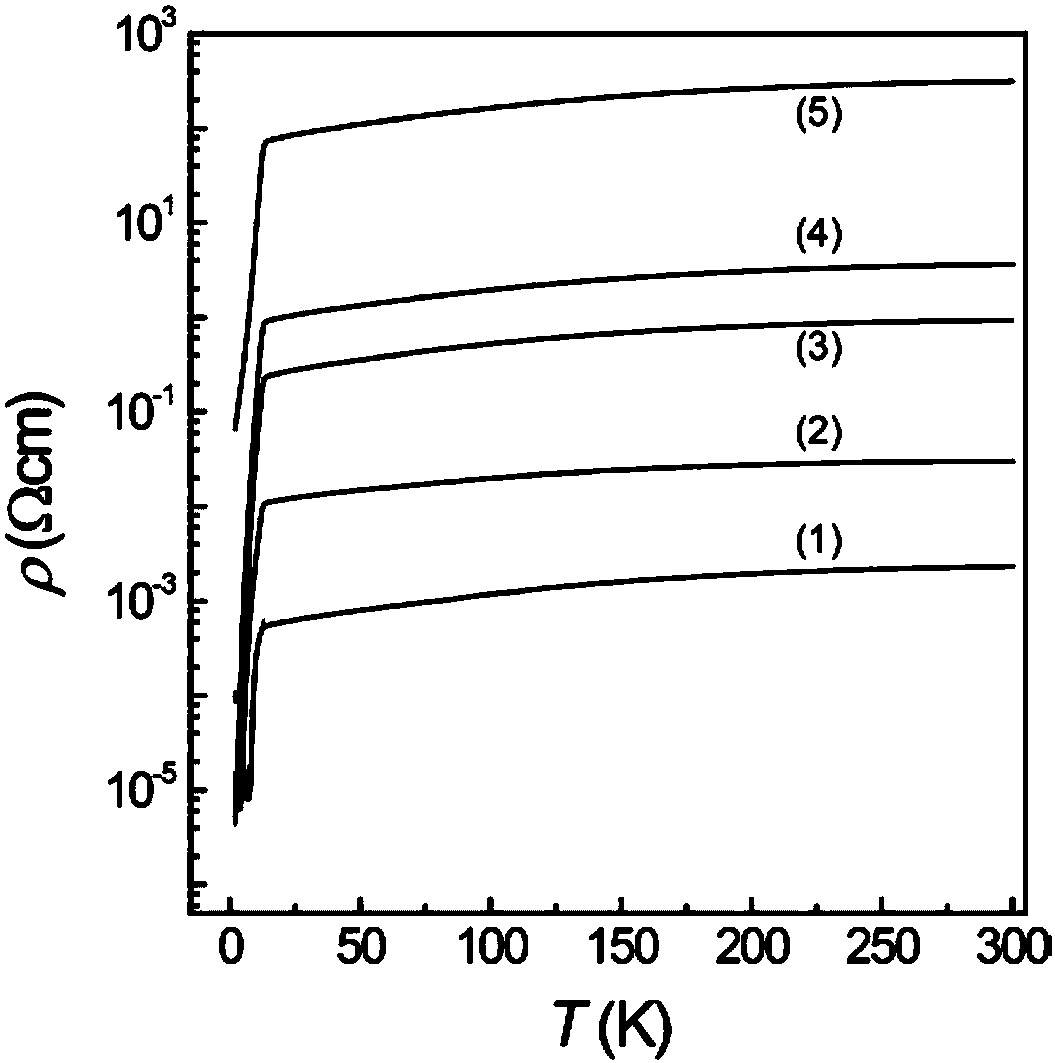

[0045] Superconducting (FeSe) 1 (SrTiO 3 ) x Material preparation, the specific preparation method is as follows:

[0046] (1) According to the molar ratio 1:x (x=0.2, 1, 4, 10, 15), weigh 5.0 g of iron selenium and strontium titanate powder in a mortar and grind for 30 minutes;

[0047] (2) Put the powder sample obtained in step (1) into a graphite mold with a diameter of 12.7mm, put it into a discharge plasma sintering furnace, pressurize it at 30MPa, evacuate it until the vacuum degree is less than 5Pa, and start to apply current to heat up and sinter for about 30min Raise the temperature to 1173K, keep it warm for 30 minutes, then release the pressure directly, and cool down to room temperature naturally;

[0048] (3) Put the sample obtained by sintering into a CVD tube furnace to anneal the sample, raise the temperature to 1173K at a rate of 10K / min under an argon atmosphere, keep the temperature constant for 90min, and then cool down. flow;

[0049] (4) Regarding sa...

Embodiment 2

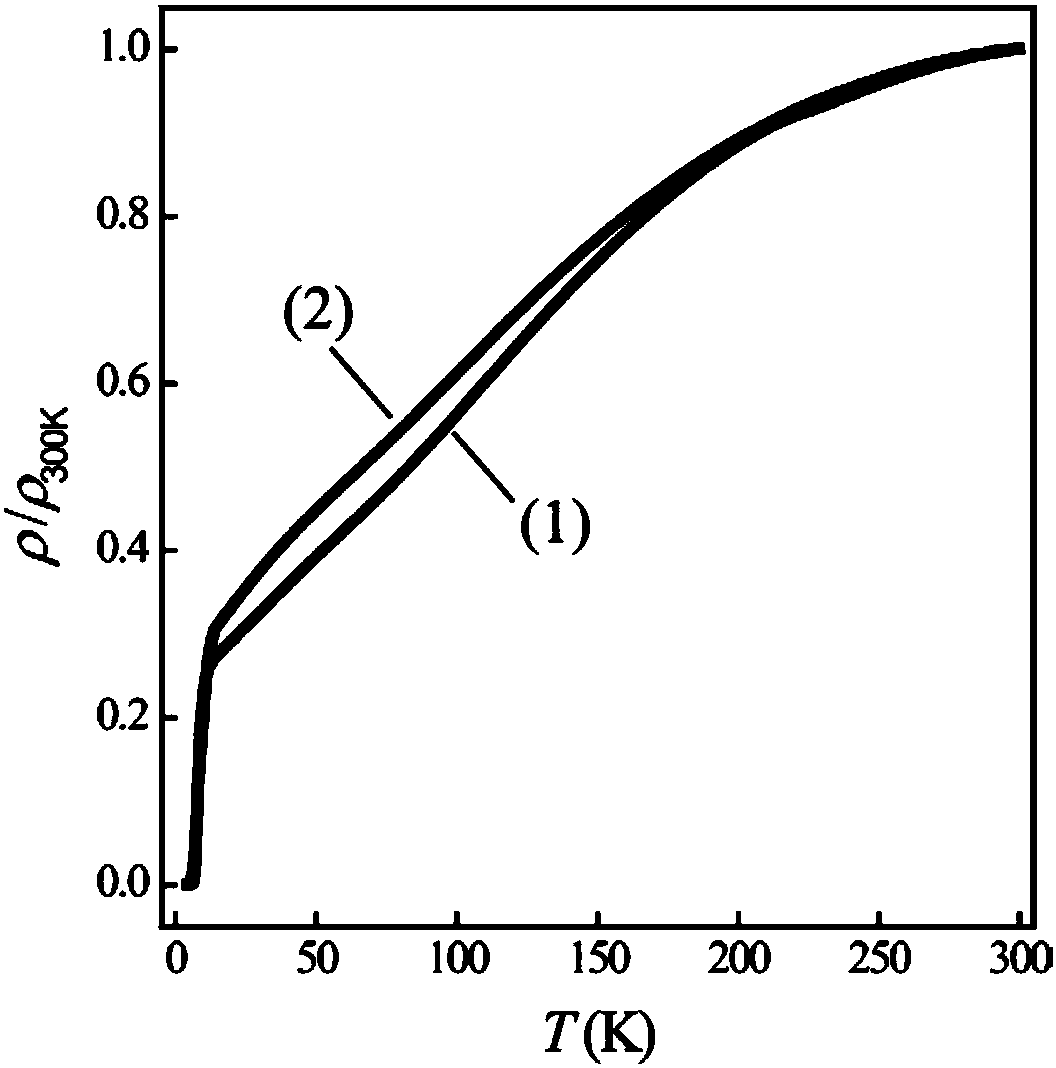

[0052] Superconducting (FeSe) 1 (BaTiO 3 ) 1 Material preparation, the specific preparation method is as follows:

[0053] (1) Weigh 5.0 g of iron selenium and barium titanate powder according to the molar ratio of 1:1, place them in an agate mortar, and grind for 30 minutes;

[0054] (2) Put the powder sample obtained in step (1) into a graphite mold with a diameter of 12.7mm, put it into a discharge plasma sintering furnace, pressurize it at 30MPa, evacuate it until the vacuum degree is less than 5Pa, and start to apply current to heat up and sinter for about 30min Raise the temperature to 1173K, keep it warm for 30 minutes, then release the pressure directly, and cool down to room temperature naturally;

[0055] (3) Put the sample obtained by sintering into a CVD tube furnace to anneal the sample, raise the temperature to 1173K at a rate of 10K / min under an argon atmosphere, keep the temperature constant for 90min, and then cool down. flow;

[0056] (4) Regarding the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| superconducting critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com