A kind of middle layer polyurethane resin for solvent-free automotive interior leather and preparation method thereof

A technology for polyurethane resin and automobile interior decoration, applied in the field of synthetic leather, can solve problems such as difficulties, achieve the effects of reducing energy consumption, ensuring continuous production operability and reactivity, and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A solvent-free polyurethane resin for the middle layer of automotive interior leather, which is composed of component A and component B mixed in a mass ratio of 2.5:1:

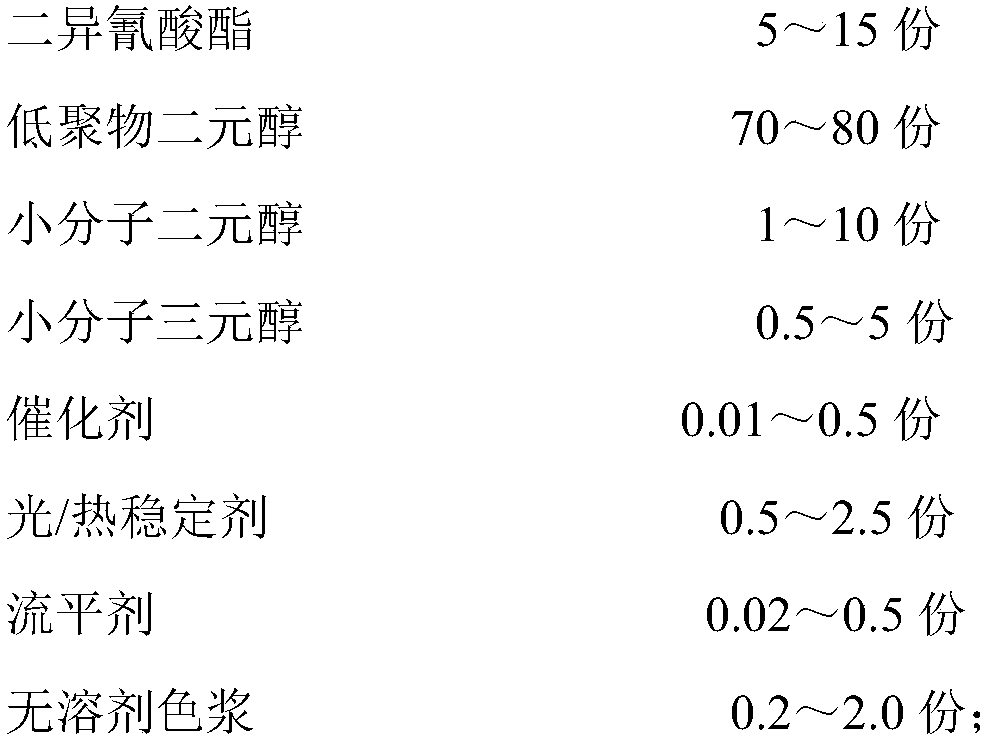

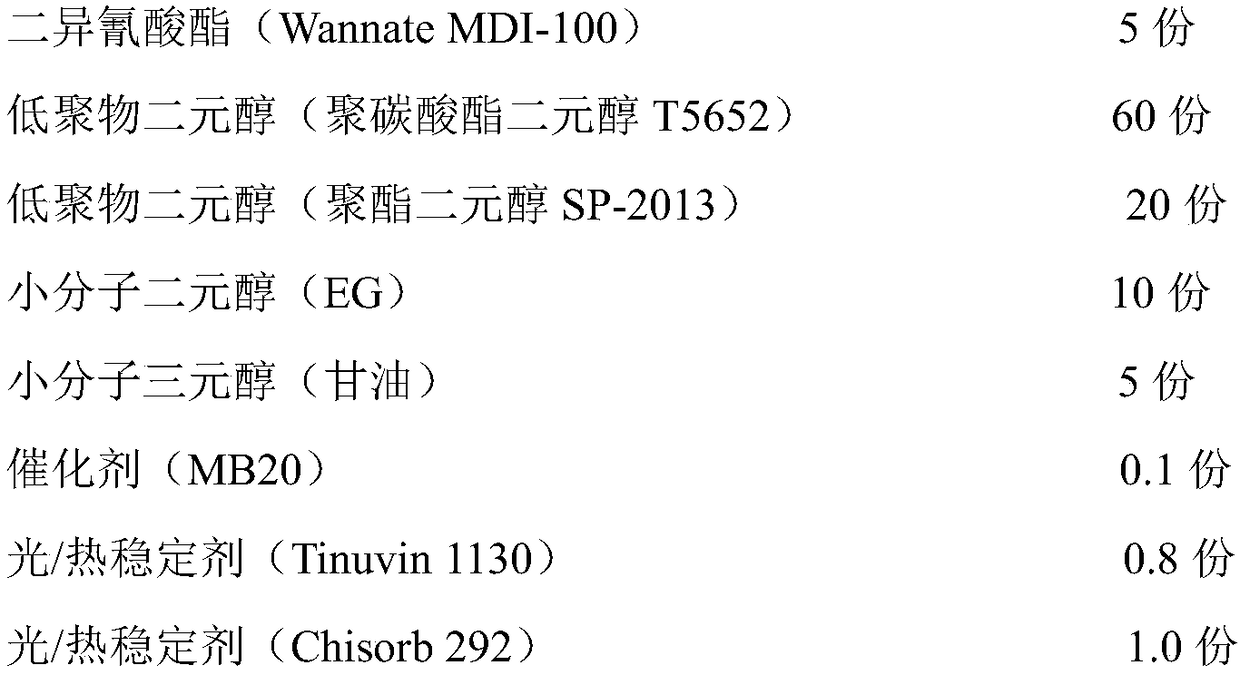

[0033] Described A component is constituted as follows according to the ratio of parts by mass:

[0034]

[0035]

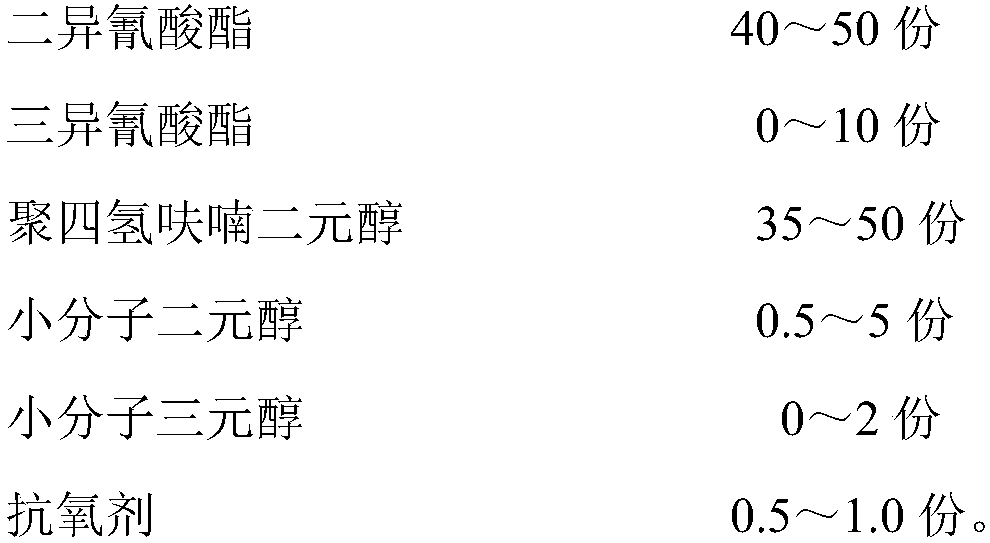

[0036] The B component is composed as follows according to the ratio of parts by mass:

[0037]

[0038] Wannate MDI-100 in component A is pure diphenylmethylene diisocyanate produced by Yantai Wanhua Company, T5652 is a polycarbonate diol with a number average molecular weight of 2000 produced by Japan Asahi Kasei Chemicals Co., Ltd., SP- 2013 is a polyester diol with a number average molecular weight of 2000 produced by Hefei Amway Polyurethane New Materials Co., Ltd., EG and glycerin are commercially available products, MB20 is an organic bismuth catalyst produced by Air Products Company of the United States, and Tinuvin 1130 is a German BASF company The ultraviolet absorber p...

Embodiment 2

[0044] A solvent-free polyurethane resin for the middle layer of automotive interior leather, which is composed of component A and component B mixed in a mass ratio of 1:2.5:

[0045] Described A component is constituted as follows according to the ratio of parts by mass:

[0046]

[0047] The B component is composed as follows according to the ratio of parts by mass:

[0048]

[0049] Wannate MDI-50 in component A is a mixture of 4,4'-MDI and 2,4'-MDI produced by Yantai Wanhua Company, and T5652 is a polycarbonate with a number average molecular weight of 2000 produced by Japan Asahi Kasei Chemicals Co., Ltd. Diol, SP-2313 is a polyester diol with a number average molecular weight of 2000 produced by Hefei Amway Polyurethane New Material Co., Ltd., 1,4-BG and trimethylolpropane TMP are commercially available products, and BiCAT 8108 is a U.S. The organic bismuth catalyst of a leading chemical company, Chisorb P and Chisorb 944 are UV absorbers and light stabilizers of ...

Embodiment 3

[0055] A solvent-free polyurethane resin for the middle layer of automotive interior leather, which is composed of component A and component B mixed in a mass ratio of 1:1:

[0056] Described A component is constituted as follows according to the ratio of parts by mass:

[0057]

[0058]

[0059] The B component is composed as follows according to the ratio of parts by mass:

[0060]

[0061] Wherein, the A component and the B component are mixed in a mass ratio of 1:1.

[0062] Wannate MDI-50 in component A is a mixture of 4,4'-MDI and 2,4'-MDI produced by Yantai Wanhua Company, and T5652 is a polycarbonate with a number average molecular weight of 2000 produced by Japan Asahi Kasei Chemicals Co., Ltd. Dibasic alcohol, 220N is the polycaprolactone diol of Nippon Chemical Industry Co., Ltd. Daicel, 1,3-PG is 1,3-propanediol produced by DuPont Company of the United States, and trimethylolpropane TMP is a commercially available product, Borchi Kat 24 is a metal salt c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com