Low-viscosity polyamide acid copolymer, preparation method of polyamide acid copolymer and polyimide film

A polyamic acid, low-viscosity technology, applied in the field of preparation of low-viscosity polyamic acid copolymers, can solve the problems of poor leveling, poor operability, affecting the performance of polyimide films, etc., and achieve good mechanical properties and insulation performance, fast drying and film formation, and the effect of improving leveling and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

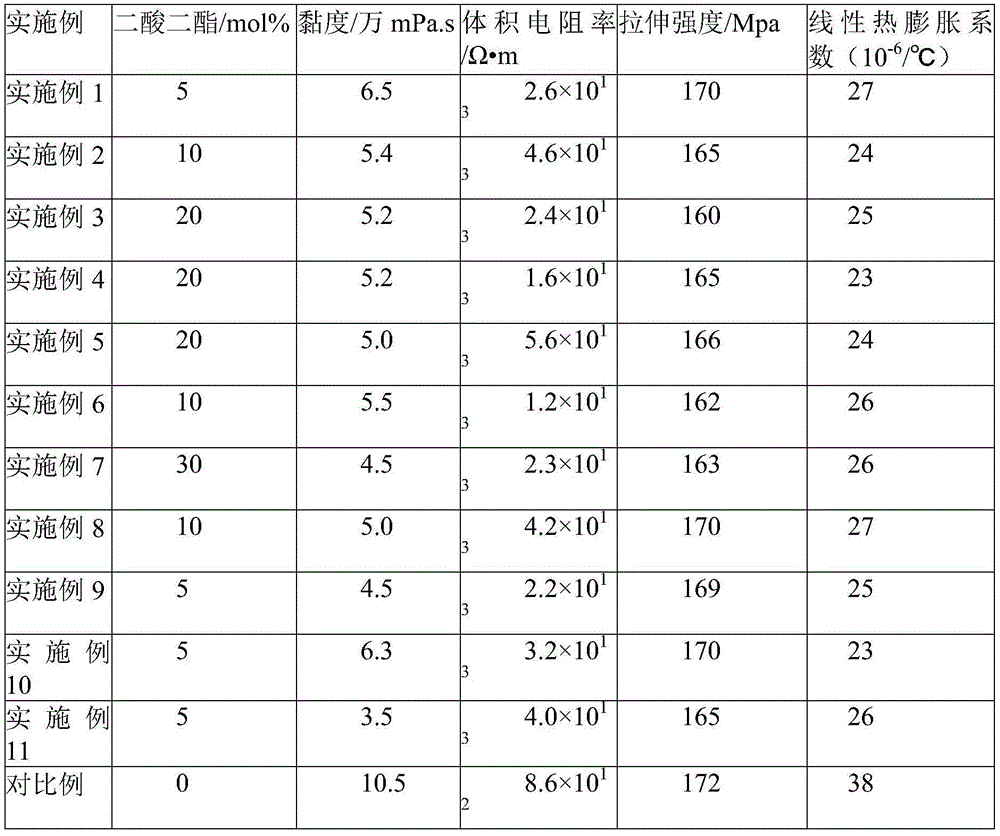

Examples

Embodiment 1

[0018] Add 10.0g of 4,4'-diaminodiphenyl ether into a three-necked flask, then add 83g of N,N-dimethylacetamide, and stir to dissolve for 40min. After the dissolution is complete, add 0.625 g of dimethyl pyromellitate and 10.34 g of pyromellitic dianhydride, the solid content of the solution is 20%, and react at room temperature for 7 hours to obtain a polyamic acid copolymer.

[0019] Under the condition of 25°C, the viscosity of the copolymer solution measured by NDJ-8S digital viscometer is 65,000 mPa.s.

Embodiment 2

[0021] Add 10.0g of 4,4'-diaminodiphenyl ether into a three-necked flask, then add 83g of N,N-dimethylacetamide, and stir to dissolve for 40min. After the dissolution is completed, 1.25 g of dimethyl pyromellitate and 9.8 g of pyromellitic dianhydride are added, the solid content of the solution is 20%, and the reaction is carried out at room temperature for 7 hours to obtain a polyamic acid copolymer.

[0022] Under the condition of 25°C, the viscosity of the copolymer solution measured by NDJ-8S digital viscometer is 54,000 mPa.s.

Embodiment 3

[0024] Add 10.0g of 4,4'-diaminodiphenyl ether into a three-necked flask, then add 83g of N,N-dimethylacetamide, and stir to dissolve for 40min. After the dissolution is complete, 2.5 g of dimethyl pyromellitate and 8.7 g of pyromellitic dianhydride are added, the solid content of the solution is 20%, and the reaction is carried out at room temperature for 7 hours to obtain a polyamic acid copolymer.

[0025] Under the condition of 25°C, the viscosity of the copolymer solution measured by NDJ-8S digital viscometer is 52,000 mPa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com