Invisible optical cable and self-adhering coating glue

A coating adhesive and self-adhesive technology, applied in optics, light guides, adhesives, etc., can solve the problems of uncured strength or poor initial tack, short opening time of self-adhesive coating adhesive, poor transparency, etc., to achieve uncured strength or Good initial tack, improved performance during processing, and long open time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

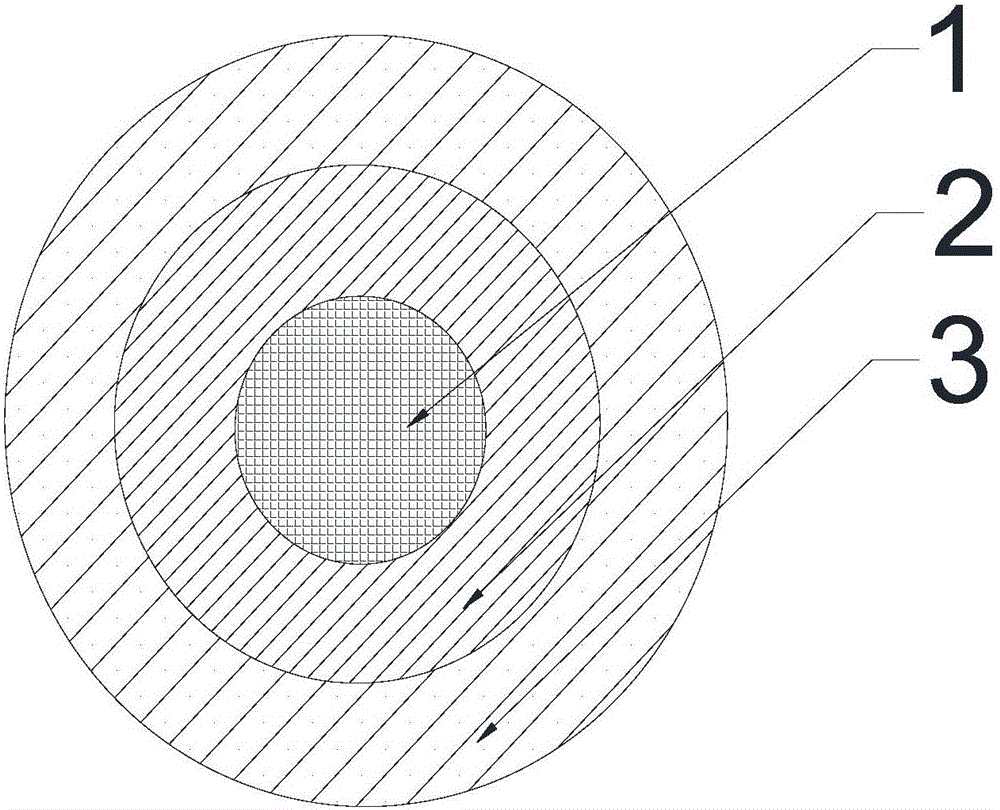

Image

Examples

Embodiment 1

[0028] Self-adhesive coating glue includes: ethylene-ethyl acrylate copolymer 45%; the content of polymerized rosin is 6%, the content of terpene resin is 7%, microcrystalline wax 30%, antioxidant 2%, chlorinated polyethylene 2% %, amorphous polypropylene 2%, hydrogenated petroleum resin 6%. The antioxidant in this example is Taiwan Chinox 1010.

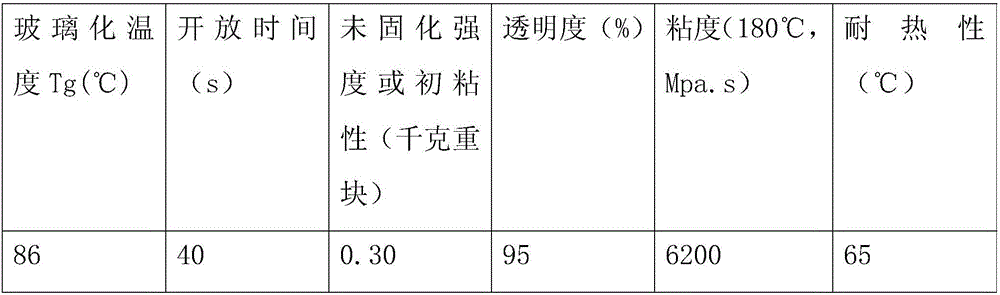

[0029] Properties of the resulting self-adhesive coating:

[0030]

Embodiment 2

[0032] Self-adhesive coating glue includes: ethylene-ethyl acrylate copolymer 45%; the content of polymerized rosin is 5%, the content of terpene resin is 6%, paraffin wax 25%, antioxidant 2%, chlorinated polyethylene 5%, Amorphous polypropylene 5%, phenolic resin 7%. The antioxidant in this example is Taiwan Chinox 1010.

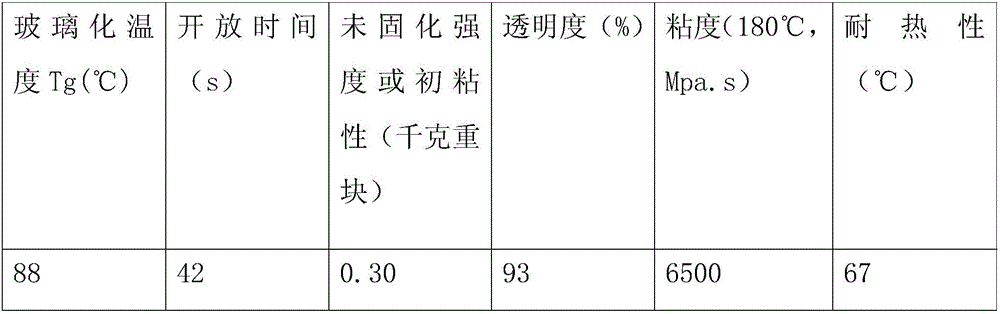

[0033] Properties of the resulting self-adhesive coating:

[0034]

Embodiment 3

[0036] Self-adhesive coating glue includes: ethylene-ethyl acrylate copolymer 42.5%; the content of polymerized rosin is 8%, the content of terpene resin is 7%, polyethylene wax 27.5%, antioxidant 2%, chlorinated polyethylene 2% %, amorphous polypropylene 3.5%, hydrogenated terpene resin 7.5%. The antioxidant in this example is Taiwan Chinox 1010.

[0037] Properties of the resulting self-adhesive coating:

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com