Carbon fiber modified non-solvent polyurethane surface layer resin for sports shoe leather, as well as preparation method and application of carbon fiber modified non-solvent polyurethane surface layer resin

A technology of solvent-free polyurethane and surface layer resin, which is applied in the field of synthetic leather, can solve the problems of DMF residue and organic solvent N,N-dimethylformamide, etc., so as to ensure environmental protection, solve difficult peeling, and improve compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of carbon fiber modified solvent-free surface layer polyurethane resin for sports shoe leather, the resin is composed of hydroxyl component A and isocyanate component B:

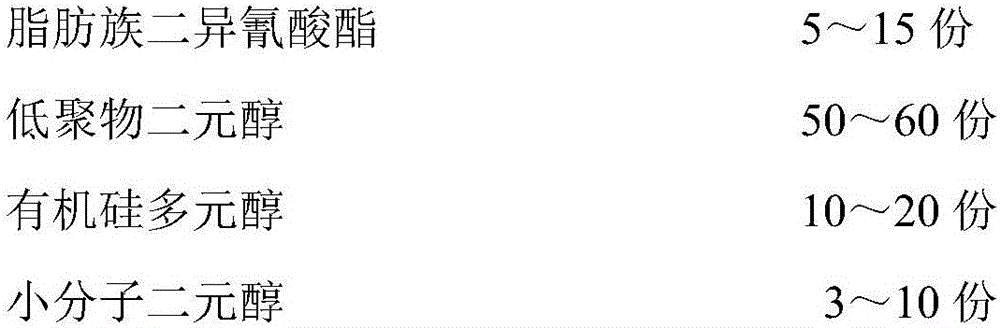

[0039] The A component is composed as follows according to the ratio of parts by mass:

[0040]

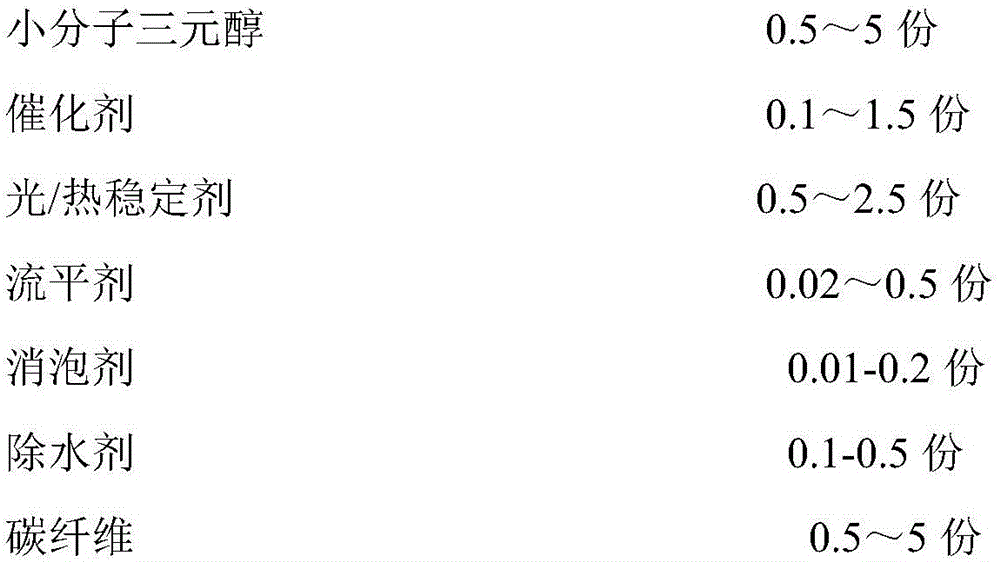

[0041] The B component is composed as follows according to the ratio of parts by mass:

[0042]

[0043] Wherein, the A component and the B component are mixed in a mass ratio of 1:1.4.

[0044]The IPDI in component A is isophorone diisocyanate produced by Bayer, Germany, T5652 is a polycarbonate diol with a number average molecular weight of 2000 produced by Asahi Kasei Chemicals Co., Ltd., and SP-2013 is Hefei Amway new polyurethane material The polyester diol with a number average molecular weight of 2000, EG and glycerin produced by the Co., Ltd. are all commercially available products. OFOH702E is the hydroxyl silicone oil with a hydroxyl value of 50mgKOH / g produced by Momentive High-te...

Embodiment 2

[0052] A kind of carbon fiber modified solvent-free surface layer polyurethane resin for sports shoe leather, the resin is composed of hydroxyl component A and isocyanate component B:

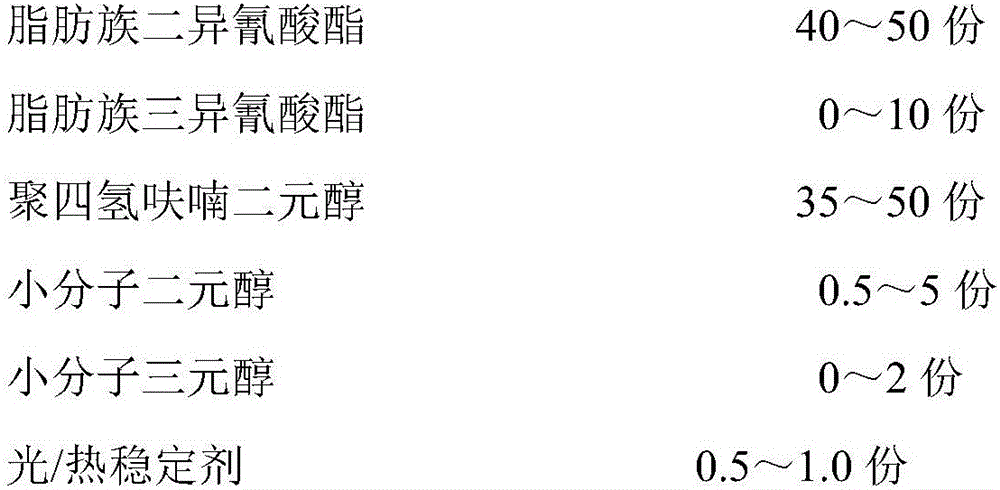

[0053] Described A component is constituted as follows according to the ratio of parts by mass:

[0054]

[0055] The B component is composed as follows according to the ratio of parts by mass:

[0056]

[0057] Wherein, the A component and the B component are mixed in a mass ratio of 1:1.

[0058] H in component A 12 MDI is hydrogenated MDI produced by Yantai Wanhua Company, T5652 is a polycarbonate diol with a number average molecular weight of 2000 produced by Asahi Kasei Chemicals Co., Ltd., and SP-2313 is a number average molecular weight of 2000 produced by Hefei Amway Polyurethane New Material Co., Ltd. OFX-0930 is a hydroxyl silicone oil with a hydroxyl value of 130mgKOH / g produced by Dow Corning, 1,4-BG and trimethylolpropane TMP are commercially available products, BiCAT 8108 ...

Embodiment 3

[0066] A kind of carbon fiber modified solvent-free surface layer polyurethane resin for sports shoe leather, the resin is composed of hydroxyl component A and isocyanate component B:

[0067] The A component is composed as follows according to the ratio of parts by mass:

[0068]

[0069] The B component is composed as follows according to the ratio of parts by mass:

[0070]

[0071] Wherein, the A component and the B component are mixed in a mass ratio of 2:1.

[0072] The IPDI in component A is isophorone diisocyanate produced by Bayer, Germany, T5652 is a polycarbonate diol with a number average molecular weight of 2000 produced by Asahi Kasei Chemicals Co., Ltd., and SP-2013 is Hefei Amway new polyurethane material The polyester diol with a number average molecular weight of 2000, EG and glycerin produced by the Co., Ltd. are all commercially available products. OFOH702E is the hydroxyl silicone oil with a hydroxyl value of 50mgKOH / g produced by Momentive High-tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com