Nanowhisker leveling thickener for paint and preparation method thereof

A technology of nano-whisker and thickener, which is applied in the field of nano-whisker leveling thickener for coatings and its preparation, can solve the problems of poor leveling, coating production, storage, construction, film-forming influence, coating sagging and other problems, to achieve the effect of adjusting viscosity, obvious anti-sagging effect, and preventing coating sag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

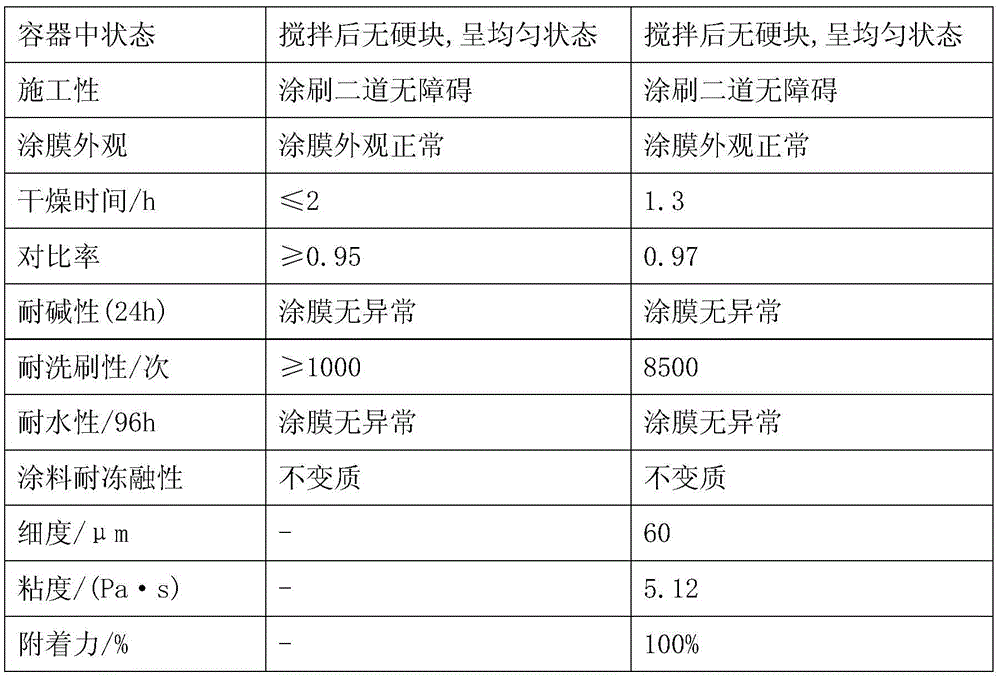

[0016] A nano-whisker leveling thickener for coatings, made of the following raw materials by weight (kg): attapulgite 32, sericite 19, dolomite 23, kyanite 25, phyllite 20, waste phosphogypsum 12. Carbide slag 8, sodium sulfate 4, barium fluoride 3, molybdenum trioxide 2, modifier A 8, modifier B 6;

[0017] Described modifier A is mixed by the raw material of following weight (kg): calcium oxalate 8, copper sulfate 6, sodium sulfide 4, diethylene glycol 8, hydroxyethyl carboxymethyl cellulose 9, sodium oleate 6, Calcium lignosulfonate 4, coconut oil fatty acid diethanolamide 3, ethoxylated fatty acid methyl ester 6;

[0018] Described modifier B is mixed by the raw material of following weight (kg): octenyl starch succinate sodium 6, polyvinylpyrrolidone 4, dodecyl trimethyl ammonium chloride 8, diisobutyl naphthalene Sodium sulfonate 5, Pingpingjia O-93, N-propyl-perfluorooctyl sulfonyl glutamate potassium 4.

[0019] A preparation method of nano-whisker leveling thickene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com