Flexible transparent conductive electrode

A transparent conductive electrode, flexible technology, applied to conductive materials dispersed in non-conductive inorganic materials, conductive layers on insulating carriers, circuits, etc., can solve the problem that the conductivity and bending resistance of silver nanowire films need to be improved, etc. Problems, achieve the effect of improving light transmittance, reducing content, and reducing conductive resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

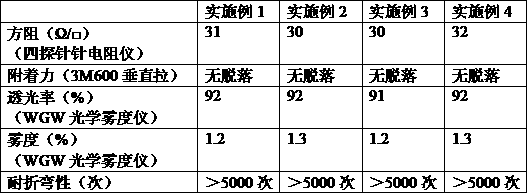

[0019] Embodiments 1 to 4: a flexible transparent conductive electrode, the flexible transparent conductive electrode is composed of a transparent flexible substrate and a silver nanowire coating coated on the surface of the transparent flexible substrate, and the thickness of the silver nanowire coating is 20 ~100 microns, the silver nanowire coating is obtained by drying the silver nanowire slurry, and the silver nanowire slurry is composed of the following components by weight, as shown in Table 1:

[0020] Table 1

[0021]

Example 1

Example 2

Example 3

Example 4

Silver nanowire aqueous dispersion

100 copies

100 copies

100 copies

100 copies

Waterborne Acrylic Resin

6 servings

5 copies

6.2 parts

7 copies

3 copies

2.2 parts

5 copies

4 parts

1.8 servings

1 copy

1.5 servings

1.2 parts

Aqueous solution of polyviny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com