Veneer mortar for whiskering-resistant outer walls

A technology for facing mortar and anti-efflorescence, which is applied in the field of facing mortar and can solve the problems of facing mortar and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

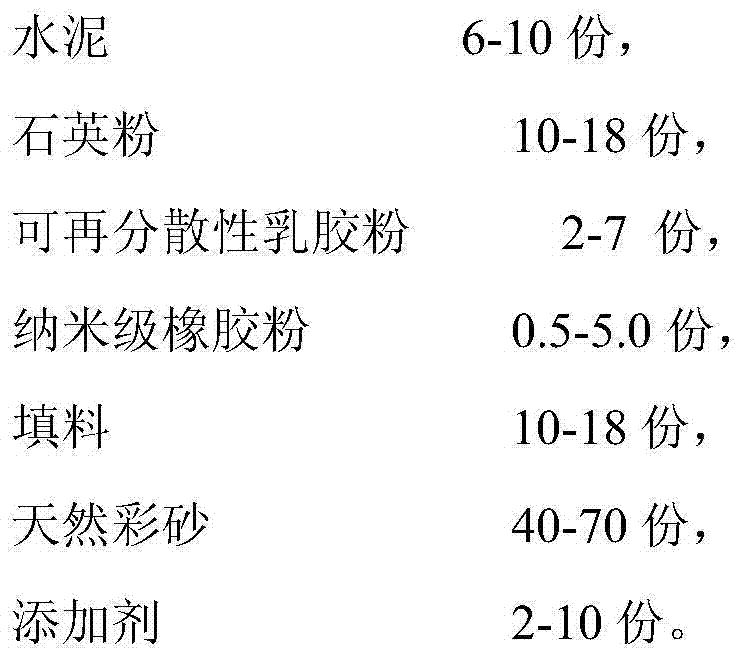

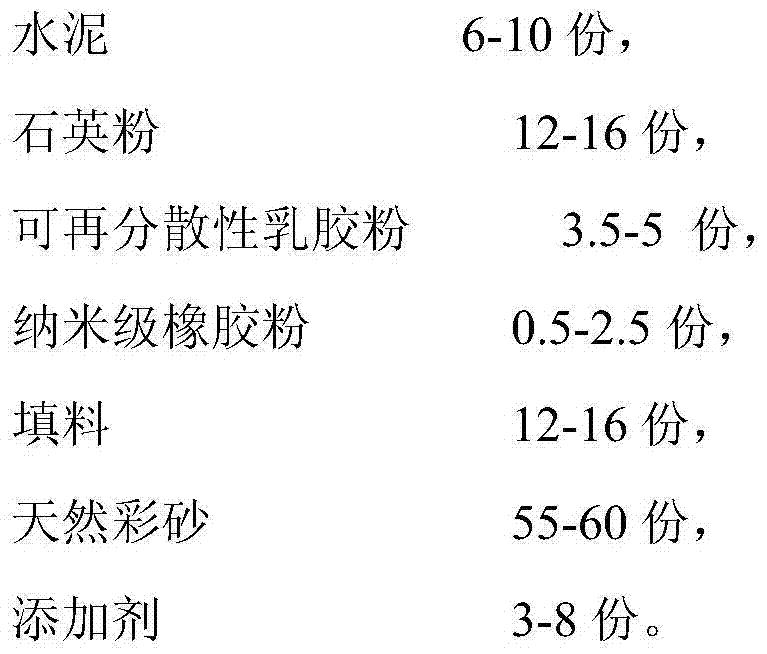

Method used

Image

Examples

example 1

[0021] The low cement-based finishing mortar for external wall insulation is composed of a mixture and water at a mass ratio of 100:20, wherein the mixture consists of 8 parts by mass of white cement, 14 parts by mass of quartz powder, 4 parts by mass of dispersible latex powder, 0.8 parts by mass of nanoscale rubber powder, 1 part by mass of reinforcing agent (composed of calcium formate and polycarboxylate superplasticizer at a ratio of 2:1), 14 parts by mass of heavy calcium, 38 parts by mass of 40-70 mesh colored sand, 200 mesh colored sand It consists of 19 parts by mass of sand, 2 parts by mass of cellulose ether, and 1 part by mass of water repellent.

[0022] Before use, the above-mentioned mixture is placed in a mixer for pre-mixing, and the mixing time is not less than 2 minutes. When in use, first add water, and then use an electric mixer to add the evenly mixed mixture while stirring. After fully stirring for 5 minutes, the slurry is left to stand for 5 minutes, a...

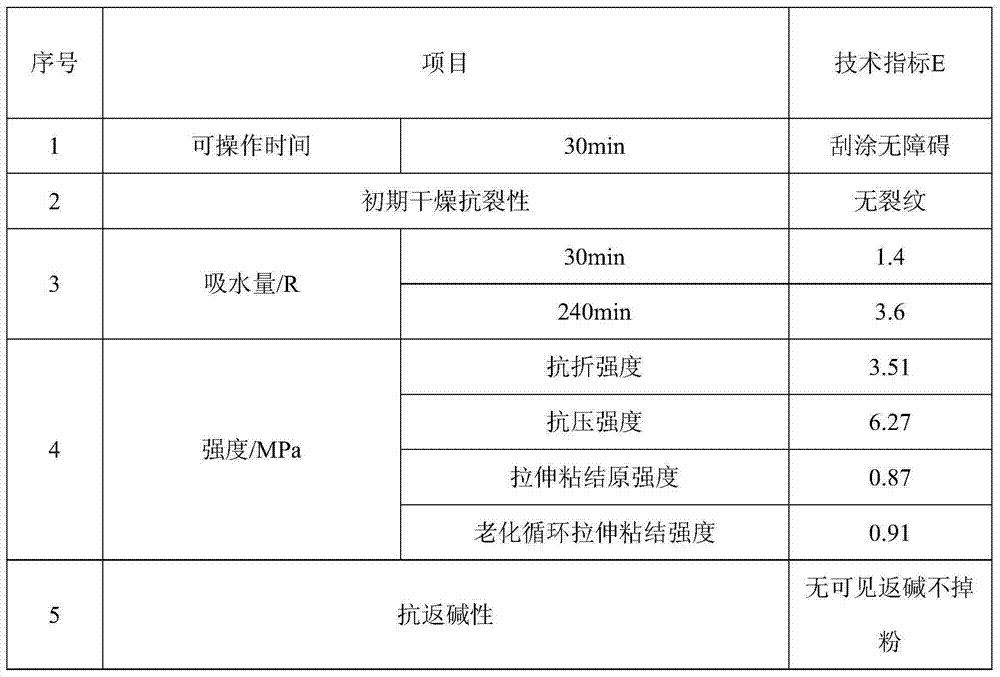

example 2

[0025] The facing mortar is composed of mixture and water at a mass ratio of 100:22, wherein the mixture consists of 10 parts by mass of white cement, 12 parts by mass of quartz powder, 5 parts by mass of dispersible latex powder, 2.5 parts by mass of nano-scale rubber powder, 1.5 parts by mass of reinforcing agent (composed of sodium sulfate and naphthalene salt water reducer at a ratio of 2:1), 12 parts by mass of heavy calcium, 42 parts by mass of 40-70 colored sand, 14 parts by mass of 200 mesh colored sand, 3 parts by mass of cellulose ether Parts, water repellent 2 mass parts composition.

[0026] Before use, the above-mentioned mixture is placed in a mixer for pre-mixing, and the mixing time is not less than 2 minutes. When in use, first add water, and then use an electric mixer to add the evenly mixed mixture while stirring. After fully stirring for 5 minutes, the slurry is left to stand for 5 minutes, and it can be used after stirring again.

[0027] According to th...

example 3

[0033] A low cement-based finishing mortar for external thermal insulation of external walls, which is composed of a mixture and water at a mass ratio of 100:23, wherein the mixture consists of 6 parts by mass of white cement, 12 parts by mass of quartz powder, and 3.5 parts by mass of dispersible latex powder 1.5 parts by mass of nanoscale rubber powder, 1.5 parts by mass of reinforcing agent (composed of calcium bromide and lignosulfonate water reducer at 2:1), 15.5 parts by mass of heavy calcium, 35 parts by mass of 40-70 colored sand , 20 parts by mass of 200-mesh colored sand, 5 parts by mass of cellulose ether, and 3 parts by mass of water-repellent agent.

[0034] Before use, the above-mentioned mixture is placed in a mixer for pre-mixing, and the mixing time is not less than 2 minutes. When in use, first add water, and then use an electric mixer to add the evenly mixed mixture while stirring. After fully stirring for 5 minutes, the slurry is left to stand for 5 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com