Method for producing baking-free brick mainly from red mud and magnesium slag by extrusion molding

A main raw material, extrusion molding technology, applied in the field of comprehensive utilization of industrial solid waste resources and new building materials, to achieve the effect of fast hardening, less space occupation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Produce unburned bricks with red mud and magnesium slag as the main raw materials, and its components are red mud, magnesium slag, active mineral materials, and lime. The mass ratio of red mud to magnesium slag, active mineral material and lime is 45:40:10:5; the active mineral material is composed of blast furnace slag, yellow phosphorus slag and fly ash in a mass ratio of 3:3:4 .

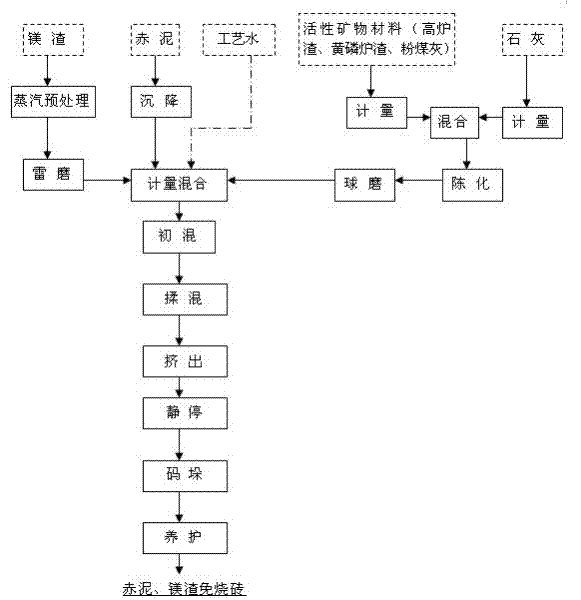

[0027] see figure 1 , a method for producing unburned bricks by extruding red mud and magnesium slag as the main raw materials, which is to pretreat magnesium slag, active mineral materials and lime, and then according to the formula of red mud: magnesium slag: active mineral material: lime The mass percentage is 45:40:10:5, mixed with red mud to obtain a mixture, and tap water is added to the mixture, and the mass ratio of the material to water is adjusted to 100:35, and then stirred, mixed, extruded, and cut , static stop, stacking blanks, steam curing and other brick-making processes t...

Embodiment 2

[0033] Example 2 : To produce unfired bricks with red mud and magnesium slag as the main raw materials, and its components are red mud, magnesium slag, active mineral materials and lime. The mass ratio of red mud to magnesium slag, active mineral material, and lime is 45:35:15:5; the active mineral material is made of blast furnace slag and fly ash mixed at a mass ratio of 2:1.

[0034] see figure 1 , a method of extruding red mud and magnesium slag as the main raw materials to produce unburned bricks is to pretreat magnesium slag, active mineral materials and lime, and then press them into red mud: magnesium slag: active mineral material: The mass percentage of lime=45:35:15:5 is mixed to obtain a mixture, and middle water is added to the mixture, and the mass ratio of the material to water is adjusted to 100:33, and then mixed, extruded, cut, and statically stopped , stacking blanks, steam curing and other brick-making processes to obtain burn-free bricks.

[0035] The r...

Embodiment 3

[0039] Example 3: Produce unburned bricks with red mud and magnesium slag as the main raw materials, and its components are red mud, magnesium slag, fly ash and lime. The mass percentage of red mud, magnesium slag, fly ash and lime is 45:40:13:2.

[0040] see figure 1 , a method for producing unburned bricks by extruding red mud and magnesium slag as the main raw materials. First, the magnesium slag is thermally activated and then mixed with lime in proportion for aging. 8% powder, then mix the material according to the mass ratio of red mud: magnesium slag: fly ash: lime is 45:40:13:2, add tap water to the mixture, and adjust the mass ratio of material to water to 100: 32. After brick making processes such as stirring and mixing, extrusion, cutting, static stopping, billet stacking, and steam curing, unburned bricks are obtained.

[0041] The red mud used is the industrial waste slag in the alumina production process of the hybrid method (it can be used directly without t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com