Efforescence resistant colored wall finishing mortar

A facing mortar and anti-efflorescence technology, which is applied in the field of building exterior wall coatings, can solve the problems such as the deterioration of the appearance quality of the wall and affect the decorative effect of the exterior wall, so as to suppress the efflorescence phenomenon, prevent excessive drying and hardening cracking, The effect of reducing the probability of ubiquitin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail through specific embodiments below.

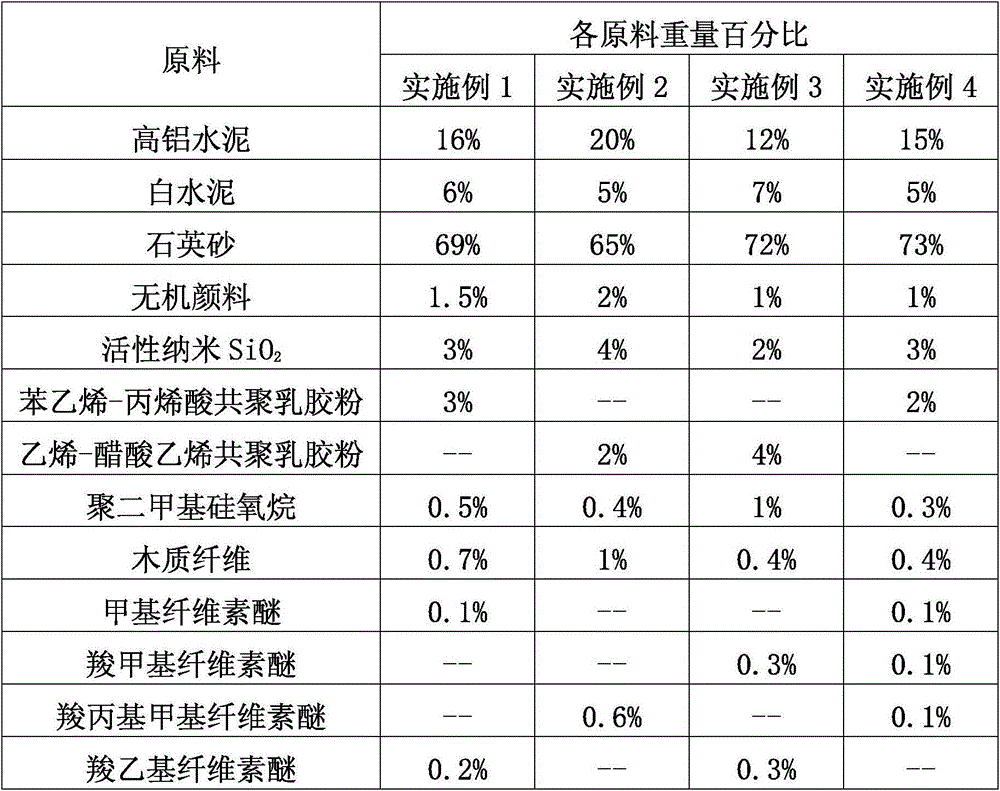

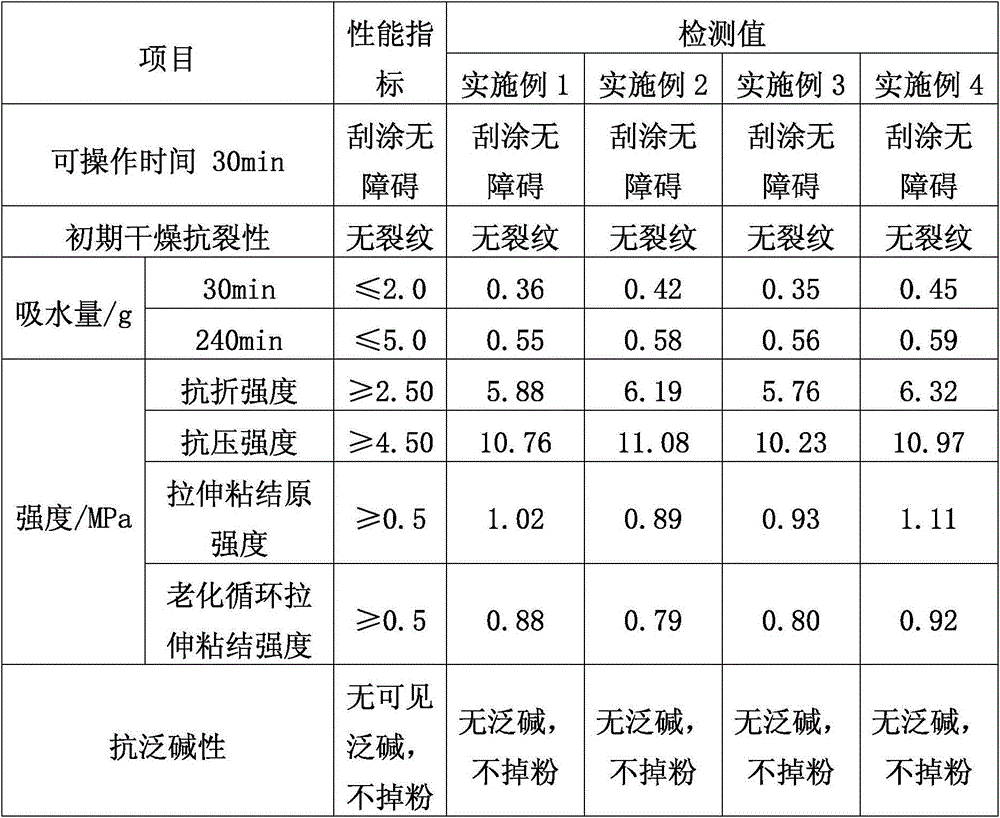

[0016] The present invention exemplifies 4 specific embodiments, and the percentage by weight of each component in all embodiments is as shown in table 1 below:

[0017] Component weight percent in each embodiment of table 1

[0018]

[0019] Weigh each raw material according to the above ratio, mix and stir evenly, then add water whose mass is 18% of the total weight of the above raw materials, fully mix and stir to obtain the product of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com