Cement hardening agent and preparing method thereof

A hardening agent and cement technology, which is applied in the field of cement infrastructure materials, can solve the problems of high cost and efflorescence, and achieve the effects of easy operation, improved hardness and wear resistance, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

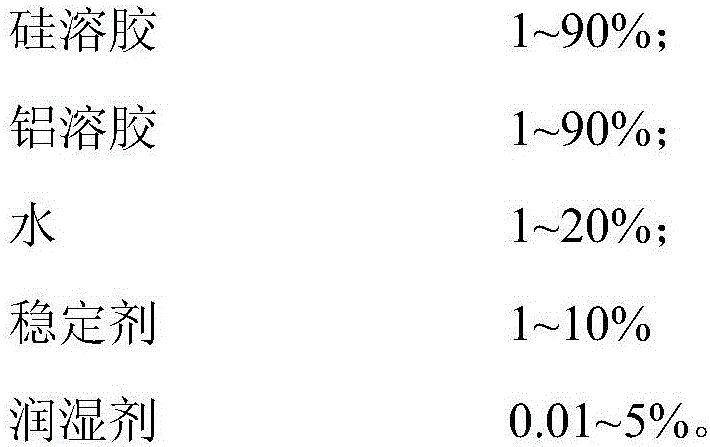

Method used

Image

Examples

Embodiment 1

[0034] Add 20 parts of water, 95 parts of silica sol, and 3 parts of 2-amino-2-methyl-1-propanol to the high-speed disperser, and disperse at a speed of 200r / min for 10min; Disperse at a speed of 300r / min for 10min to obtain a slurry; add 2 parts of wetting agent alkylphenol polyoxyethylene ether to the slurry at a speed of 300r / min, stir and disperse for 10min to obtain the water-based hardener of the present invention.

Embodiment 2

[0036] Add 10 parts of water, 5 parts of silica sol, and 5 parts of 2-amino-2-methyl-1-propanol to the high-speed disperser, and disperse at a speed of 200r / min for 10min; Disperse at a speed of 300r / min for 10min to obtain a slurry; add 1 part of wetting agent polyether silicone to the slurry at a speed of 300r / min, stir and disperse for 10min to obtain the water-based hardener of the present invention.

Embodiment 3

[0038] Add 5 parts of water, 40 parts of silica sol, and 3 parts of 2-amino-2-methyl-1-propanol to the high-speed disperser, and disperse at a speed of 200r / min for 10min; Disperse for 10 minutes at a speed of 300 r / min to obtain a slurry; add 1 part of wetting agent alkylphenol polyoxyethylene ether to the slurry at a speed of 300 r / min, stir and disperse for 10 minutes to obtain the water-based hardener of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com