Super-high-toughness concrete decorative plate and preparation method thereof

A technology of ultra-high toughness and concrete, which is applied in the field of building decoration materials, can solve problems such as fire resistance, easy aging, and pollution, and achieve the effect of less mold consumption, high production efficiency, and no damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

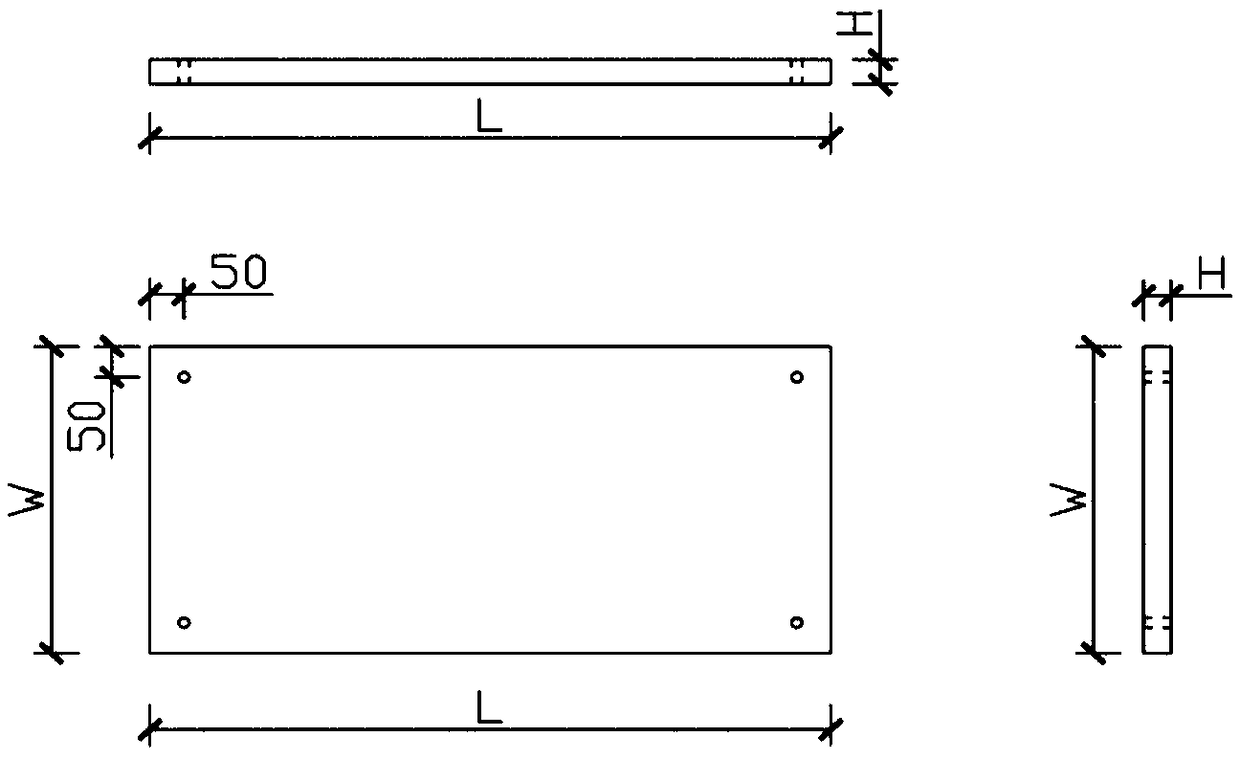

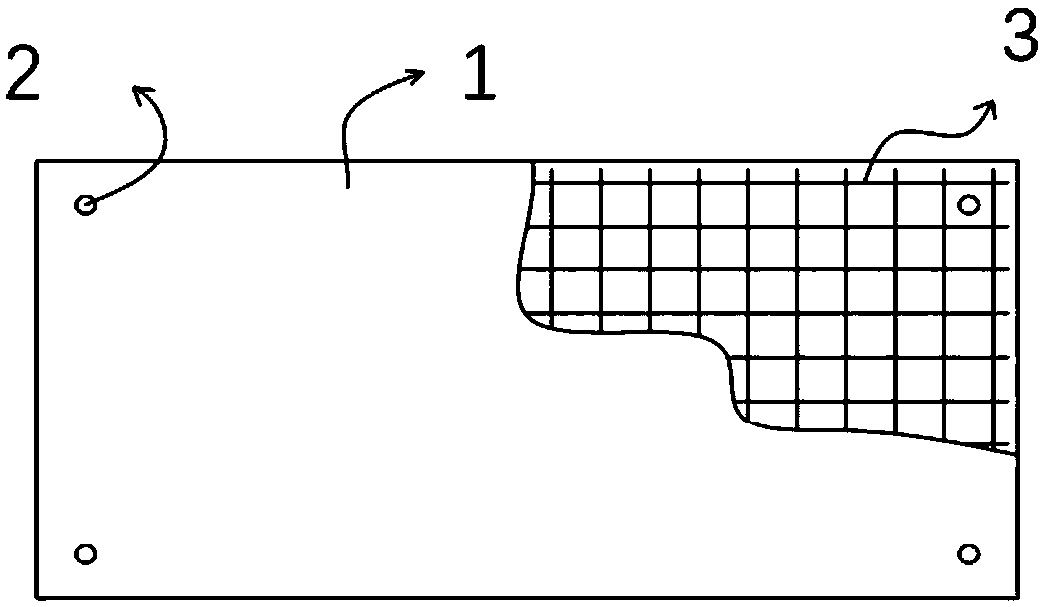

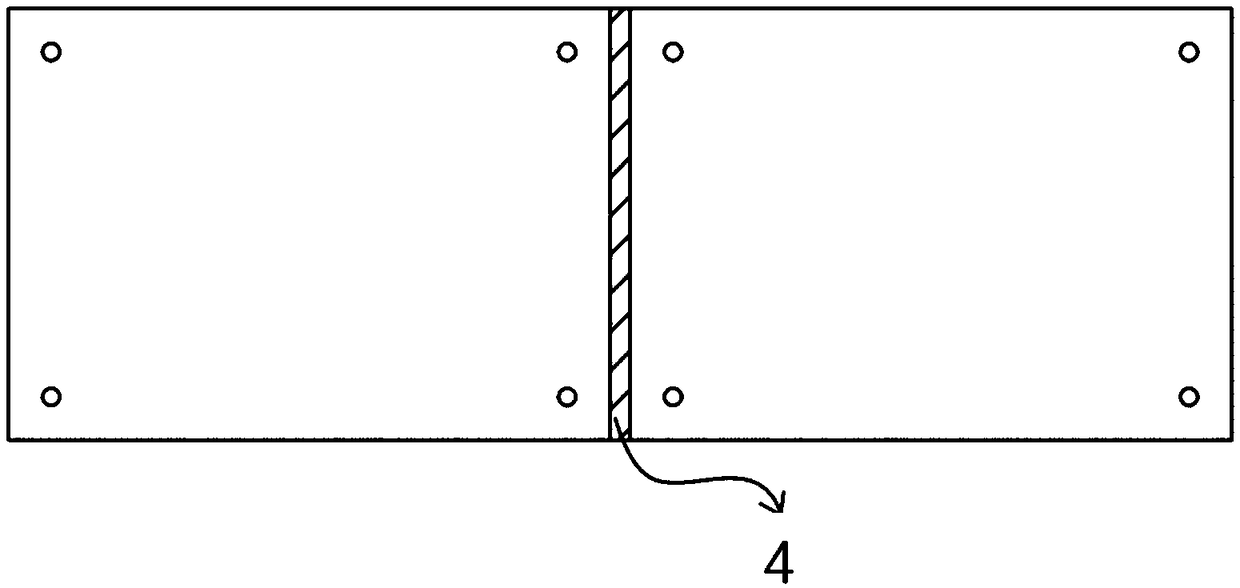

[0067] An ultra-high-toughness concrete inorganic decorative board, the inorganic decorative board is prefabricated by super-high-toughness concrete with a compressive strength greater than 100 MPa, a bending strength greater than 16 MPa, and an electric flux less than 100 coulombs plus reinforcement. The four corners of the decorative boards contain through mounting bolt holes, and the adjacent decorative boards are connected by structural sealant, wherein the reinforcement is a criss-cross fiber mesh and the surface of the reinforcement is impregnated with a reinforcing resin, The reinforcement is located in the interlayer of the decorative board, and the upper and lower surfaces of the reinforcement are respectively covered with a layer of concrete material.

[0068] The ultra-high-performance concrete inorganic decorative board prepared by using ultra-high toughness concrete includes the following raw materials in parts by weight:

[0069] 500 parts of continuously graded ...

Embodiment 2

[0093] Except that the formula of ultra-high toughness concrete inorganic decorative board is different, other conditions are the same as embodiment 1.

[0094] An ultra-high toughness concrete inorganic decorative board and a preparation method thereof, comprising the following raw materials in parts by weight:

[0095] 800 parts of continuously graded colored coarse aggregate with a particle size of 3-8 mm;

[0096] 600 parts of fine aggregate with a particle size of 0.15-2.36mm;

[0097] 750 parts of cement whose strength is not less than 32.5MPa;

[0098] 450 parts of admixtures with an average particle size of 5-30 μm;

[0099] 20 parts of organic fibers with a length of 10-20 mm;

[0100] 50 parts of pigment powder;

[0101] 25 parts of high-performance admixture;

[0102] The ratio of water to glue is 0.22.

Embodiment 3

[0104] Except that the formula of ultra-high toughness concrete inorganic decorative board is different, other conditions are the same as embodiment 1

[0105] An ultra-high toughness concrete inorganic decorative board, comprising the following raw materials in parts by weight:

[0106] 575 parts of continuously graded colored coarse aggregate with a particle size of 3-8 mm;

[0107] 450 parts of fine aggregate with a particle size of 0.15-2.36 mm;

[0108] 450 parts of cement whose strength is not less than 32.5MPa;

[0109] 260 parts of admixtures with an average particle size of 5-30 μm;

[0110] 8.5 parts of organic fibers with a length of 10-20 mm;

[0111] 28 parts of pigment powder;

[0112] 17.5 parts of high-performance admixture;

[0113] The ratio of water to glue is 0.17.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com