Red mud and aluminum ash based steam-curing-free aerated concrete and preparation method thereof

An air-entrained concrete, steam-free technology, applied in the field of air-entrained concrete, can solve the problems of high energy consumption of air-entrained concrete, difficulty in viscous foaming of freshly mixed red mud slurry, etc., and achieve the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A red mud, aluminum ash-based non-steam-curing aerated concrete. The aerated concrete is made of a powder material mixed with an appropriate amount of water and aged and foamed at room temperature; water accounts for 50% of the powder material, and the water reducer accounts for 1% of powder material;

[0034] Wherein, the components and their mass fractions in the powder material are: 20% calcareous gelling material, 15% aluminum ash, and 65% red mud.

[0035] 1) Add water and stir and mix the powder material according to the formula of Example 1 to prepare a slurry;

[0036] 2) Pour the slurry obtained in step 1) into the mold for foaming, and then stop and cure at room temperature for 1-3 hours to thicken;

[0037] 3) After the static stop curing, the test piece is demoulded and cut to obtain the green body of the required size; then the green body is naturally cured for 7 days to obtain the finished product.

Embodiment 2

[0039] A red mud, aluminum ash-based non-steam-curing aerated concrete. The aerated concrete is made of a powder material mixed with an appropriate amount of water and aged and foamed at room temperature; water accounts for 40% of the powder material, and the water reducer accounts for 0.75% of powder material;

[0040] Wherein, the components and their mass fractions in the powder material are: 25% calcareous gelling material, 25% aluminum ash, and 50% red mud.

[0041] 1) Add water and stir and mix the powder material according to the formula of Example 2 to prepare a slurry;

[0042] 2) Pour the slurry obtained in step 1) into the mold for foaming, and then stop and cure at room temperature for 1-3 hours to thicken;

[0043] 3) After the static stop curing, the test piece is demoulded and cut to obtain the green body of the required specification and size; then the green body is naturally cured for 7 days to obtain the finished product.

Embodiment 3

[0045] A kind of red mud, aluminum ash-based non-steam-curing aerated concrete. The aerated concrete is made of powder materials and appropriate amount of water to mix the slurry at room temperature for aging and foaming; water accounts for 30% of the powder materials, and the water reducer accounts for 0.5% of powder material;

[0046] Wherein, the components and their mass fractions in the powder material are: 30% calcareous gelling material, 30% aluminum ash, and 40% red mud.

[0047] 1) Add water and stir and mix the powder material according to the formula of Example 3 to prepare a slurry;

[0048] 2) Pour the slurry obtained in step 1) into the mold for foaming, and then stop and cure at room temperature for 1 to 3 hours to thicken;

[0049] 3) After the static stop curing, the test piece is demoulded and cut to obtain the green body of the required specification and size; then the green body is naturally cured for 7 days to obtain the finished product.

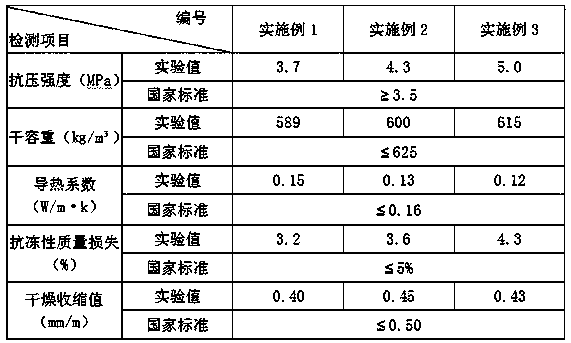

[0050]Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com