A non-fired brick with red mud and magnesium slag as the main materials

A technology of unburned bricks and magnesia slag, applied in the fields of comprehensive utilization of resources and new building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

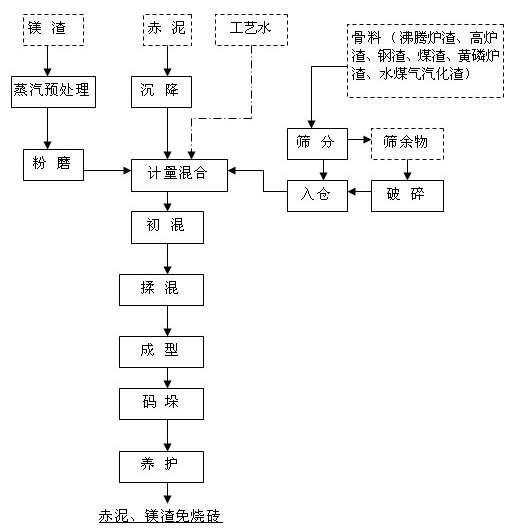

Image

Examples

Embodiment 1

[0029] Example 1 : To produce unfired bricks pressed and formed with red mud and magnesium slag as the main materials. The composition is red mud, magnesium slag, aggregate, and the dry basis mass ratio of red mud, magnesium slag, and aggregate is 45:40:15 , the aggregate is SiO 2 +Al 2 o 3 =85% boiling slag.

[0030] The red mud and magnesium slag are the main materials of the method of pressing and forming unburned bricks to produce unburned bricks. The red mud and magnesium slag are used as the main raw materials, and other industrial waste residues are used as aggregates. The mass ratio of red mud: magnesium slag: aggregate is 45: Prepare the mixture at 40:15, add process water to adjust the mass ratio of mixture to water to 100:30, and then go through the brick-making processes such as primary mixing, forced mixing, static pressure forming, billet stacking, and steam curing to obtain unburned bricks.

[0031] The red mud is the industrial waste of the sintering metho...

Embodiment 2

[0035] Example 2: Example 1: Production of unfired bricks that are pressed and formed with red mud and magnesium slag as the main materials. The components are red mud, magnesium slag, boiling slag, coal slag, and the dry weight of red mud, magnesium slag, boiling slag, and coal slag The ratio is 45:40:10:5, the aggregate is a mixture of boiling slag and cinder, SiO in the mixture 2 +Al 2 o 3 =67%.

[0036] The red mud and magnesium slag are the main materials of the method of pressing and forming unburned bricks. The red mud and magnesium slag are used as the main raw materials, and the boiling slag and coal slag are used as aggregates. Red mud: magnesium slag: boiling slag: coal slag = 45 : 40:15 mass ratio batching, add process water to adjust the mass ratio of mixture to water to 100:31, and then go through the brick making processes such as primary mixing, forced mixing, static pressure forming, stacking blanks, steam curing, etc., to obtain unfired brick.

[0037] ...

Embodiment 3

[0042] Example 3: Production of unfired bricks with red mud and magnesium slag as the main materials, which are composed of red mud, magnesium slag, and aggregate. The mass ratio of red mud, magnesium slag, and aggregate is 50:40:10, and the aggregate is SiO 2 +Al 2 o 3 =70% blast furnace slag.

[0043] The red mud used is the industrial waste slag produced in the alumina production process of the hybrid method, the magnesium slag is the industrial waste slag discharged from the production of metal magnesium by the Pidgeon method in the silicon thermal reduction method, and the process water added is the alkali-containing waste water recovered by the paper mill .

[0044] Magnesium slag pretreatment: Put the magnesium slag into a square basket without a top cover and with Φ3 small holes on each side. The square basket is placed on the maintenance trolley, and is sent to the steam curing kettle by the transfer vehicle, and is treated by 1.0MPa steam. After 3 hours, cool n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com