Process for recycling red mud dealkalization waste liquid and support equipment of process

A technology of reuse and dealkalization, applied in sludge treatment, solid waste management, metallurgical wastewater treatment, etc., can solve the problems of difficult recovery of dealkalized waste liquid and high treatment cost, and achieve the reduction of land occupation cost, reasonable layout, and realization of The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

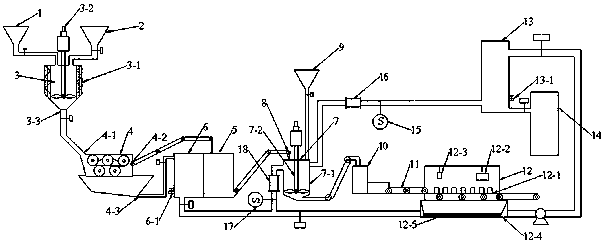

[0029] A red mud dealkalization waste liquid reuse equipment, such as figure 1As shown, it includes a dealkalization device 3, a filter press 4, a dealkalization red mud storage device 5, a brick making mixer 7, a brick making device 10, a dealkalization waste liquid storage device 6 and a curing shed 12, and the dealkalization device 3 includes The dealkalization reaction kettle 3-1 and the temperature control agitator 3-2 are arranged in the dealkalization reaction kettle 3-1, and the dealkalization reaction kettle 3-1 is provided with red mud quantitative feeding port 1, dealkalization agent and water The quantitative feeding port 2; the discharge port 3-3 of the dealkalization device 3 is arranged at the bottom of the dealkalization reaction kettle 3-1.

[0030] The filter press 4 comprises a mud inlet 4-1, a filter cake outlet 4-2 and a filtrate outlet 4-3, and the outlet 3-3 of the dealkalization device 3 is connected to the mud inlet 4-1 of the filter press 4, and the ...

Embodiment 2

[0035] A red mud dealkalization waste liquid reuse process, utilizing the equipment in embodiment 1 to perform, the steps include:

[0036] (1) Add water and dealkalization agent to the red mud for dealkalization treatment of red mud: send water and dealkalizer lime according to the mass ratio of 20:1 from the quantitative feeding port 2 of dealkalizer and water into the dealkalization reaction kettle 3-1 in the dealkalization device 3, at the same time, the sintered red mud is sent into the dealkalization reaction kettle 3-1 through the red mud quantitative feeding port 1, wherein the weight of water is added It is 4 times the total weight of red mud and lime; water, lime and sintered red mud are reacted for 12 hours under the agitation of the temperature-controlled stirrer 3-2 in the dealkalization reactor 3-1, and the reaction temperature is 75°C. After the dealkalization treatment, the reactant is discharged from the outlet 3-3 located at the bottom of the dealkalization r...

Embodiment 3

[0044] A red mud dealkalization waste liquid reuse process, utilizing the equipment in embodiment 1 to perform, the steps include:

[0045] (1) Add water and dealkalization agent to the red mud for dealkalization treatment of red mud: send water and dealkalizer lime according to the mass ratio of 20:1 from the quantitative feeding port 2 of dealkalizer and water into the dealkalization reaction kettle 3-1 in the dealkalization device 3, at the same time, the sintered red mud is sent into the dealkalization reaction kettle 3-1 through the red mud quantitative feeding port 1, wherein the weight of water is added It is 3.33 times of the total weight of red mud and lime; water, lime and sintered red mud are reacted for 12 hours under the agitation of temperature-controlled agitator 3-2 in dealkalization reactor 3-1, and the reaction temperature is 80°C. After the dealkalization treatment, the reactant is discharged from the outlet 3-3 located at the bottom of the dealkalization re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com