Concrete primer, preparation method of concrete primer and concrete structure body

A concrete and primer technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of concrete decorative coating peeling off, poor water resistance and air permeability, and alkali-resistant primer peeling off, and achieve strong salt-alkali dialysis resistance and hydrolysis resistance Excellent performance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0112] According to a second aspect of the present invention, a kind of preparation method of above-mentioned concrete primer is provided, comprising the following steps:

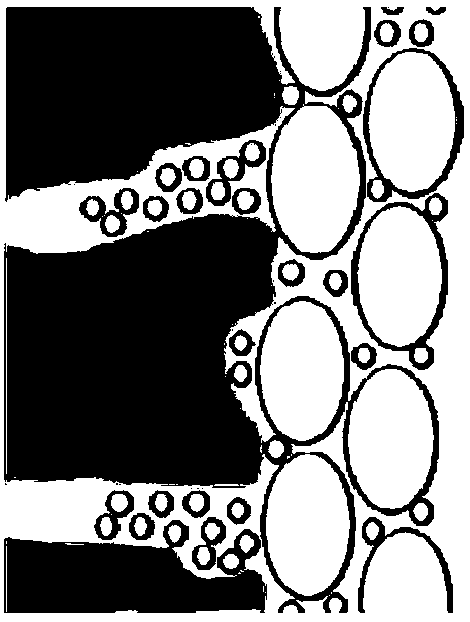

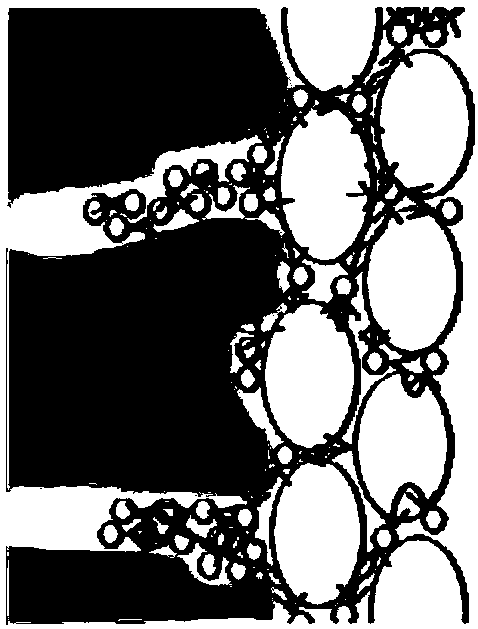

[0113] mixing and grinding water, cellulose (B), filler (C) and additive (D), adding film-forming substance (A), and mixing to obtain a concrete primer;

[0114] The film-forming substance (A) is a styrene-acrylate copolymer emulsion (A1) with an emulsion particle size distribution below 0.06 μm, a styrene-acrylate copolymer emulsion (A2) with an emulsion particle size distribution of 0.4-1 μm, optional It is obtained by mixing the styrene-acrylate copolymer emulsion (A3) whose particle size distribution is 0.08-0.2 μm, and the self-crosslinking acrylic emulsion (A4) whose particle size distribution is below 0.06 μm.

[0115] The method is simple and easy to operate and control, has low energy consumption and low cost, and is very suitable for industrial production.

[0116] Preferably, the preparation met...

Embodiment 1-6

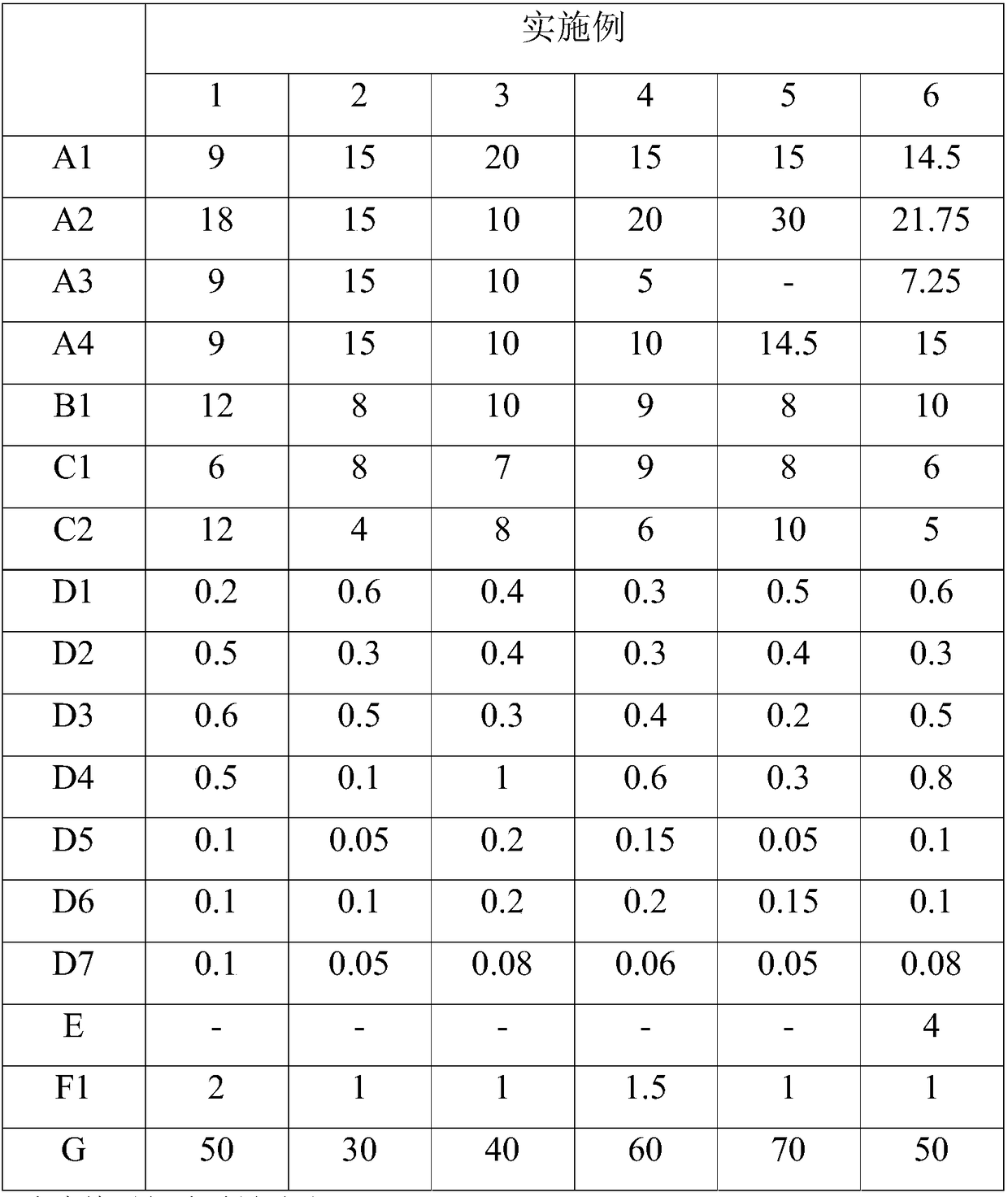

[0125] The composition of raw materials of Examples 1-6 is shown in Table 1.

[0126] The specific components are as follows:

[0127] (A) Film-forming substances

[0128] A1 Styrene-acrylate copolymer emulsion: the particle size distribution of the emulsion is 0.04-0.06μm;

[0129] A2 Styrene-acrylate copolymer emulsion: the particle size distribution of the emulsion is 0.4-1μm;

[0130] A3 Styrene-acrylate copolymer emulsion: the particle size distribution of the emulsion is 0.08-0.2μm;

[0131] A4 self-crosslinking acrylic emulsion: emulsion particle size distribution 0.04-0.06μm;

[0132] (B) Cellulose

[0133] B1 Hydroxycellulose;

[0134] (C) filler

[0135] C1 heavy calcium: particle size distribution 40-60μm;

[0136] C2 kaolin: the particle size distribution is less than 160 μm, and the content rate of particles with a particle size less than 10 μm is 20-30%;

[0137] (D) Auxiliary

[0138] D1pH regulator: 2-amino-2-methyl-propanol;

[0139] D2 dispersant: s...

Embodiment 7

[0155] The difference between this example and Example 1 is that a self-made self-crosslinking acrylic emulsion is used, and the preparation method is as follows:

[0156] (1) the butyl acrylate of 15 weight parts, the acrylamide of 2 weight parts, the sodium dodecylbenzene sulfonate of 2 weight parts and the water of 60 weight parts are mixed under ice bath, form pre-emulsion; The emulsion was warmed up to 50°C, and then 15 parts by weight of butyl acrylate, 2 parts by weight of acrylamide, 1 part by weight of sodium dodecylbenzenesulfonate, and 1 part by weight of supernatant were added dropwise to the pre-emulsion within 3 hours. Potassium sulfate, after the dropwise addition is completed, the temperature is raised to 80 ° C, and the temperature is kept for 4 hours to form emulsion I;

[0157] (2) Emulsion II obtained by mixing 2 parts by weight of methyl methacrylate, 1 part by weight of alkylphenol polyoxyethylene ether phosphate and 25 parts by weight of water in an ice ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com