Method for preventing dialysis of end face of liquid packaging paper material

A paper-based packaging material, end-face technology, applied in packaging, wrapping paper, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

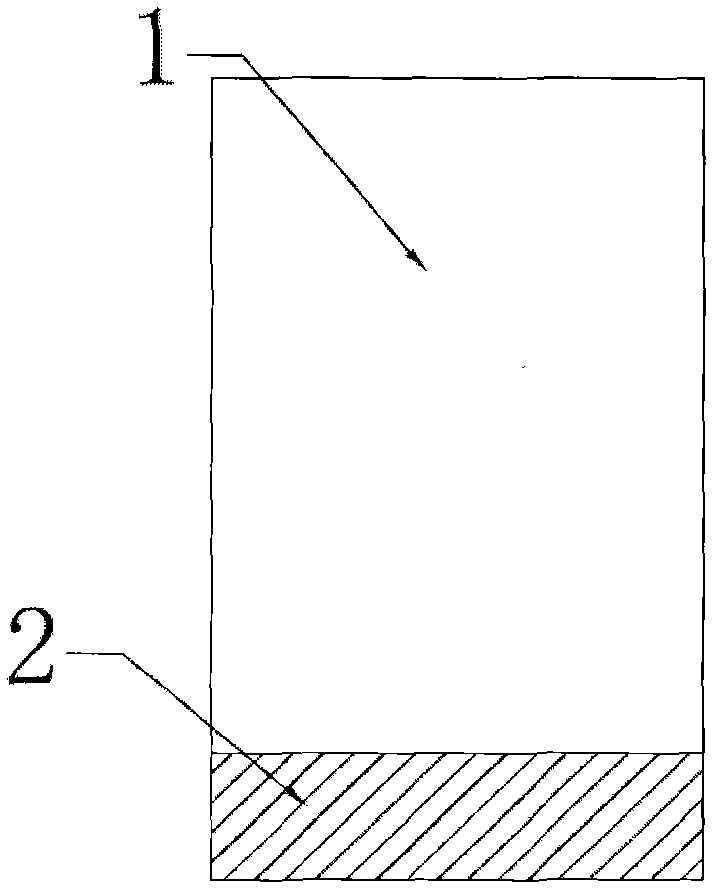

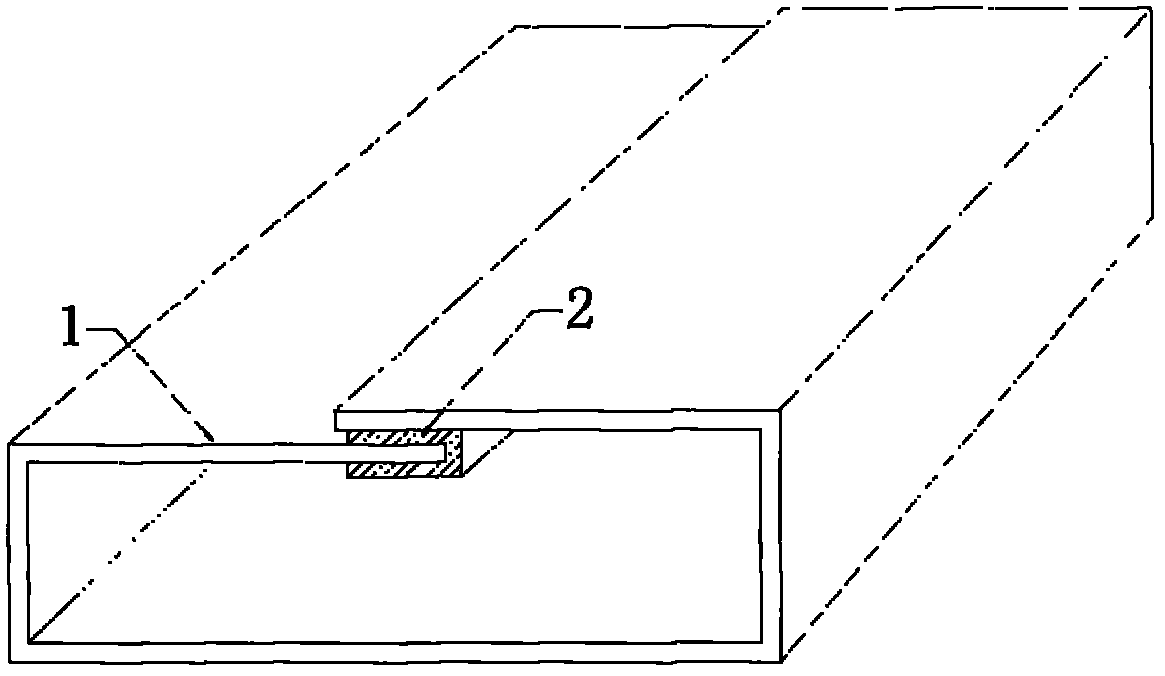

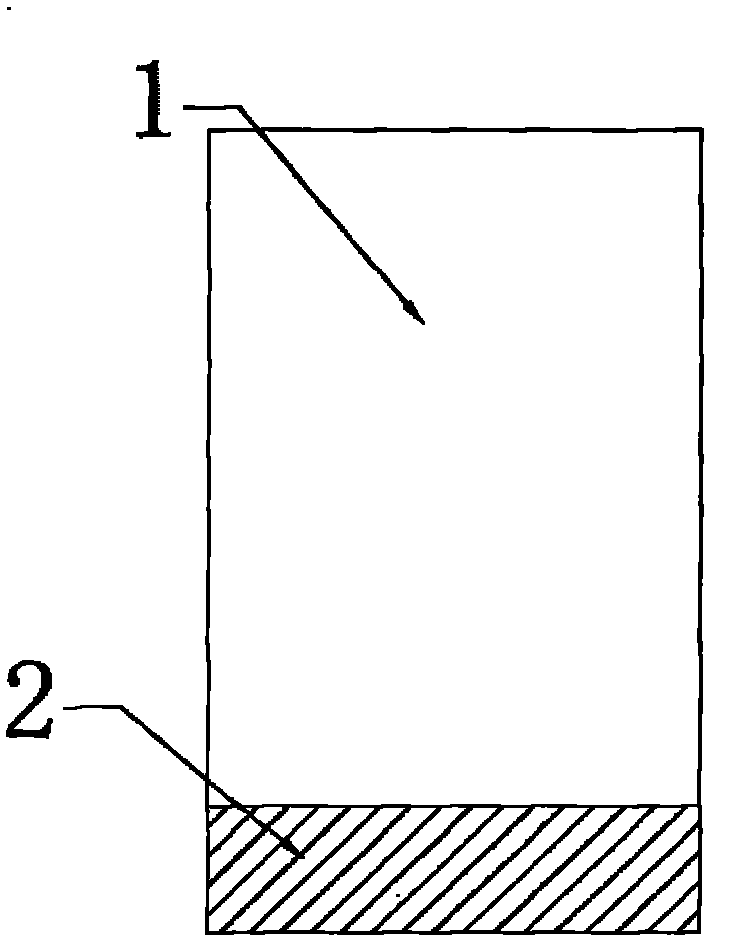

[0019] Such as figure 1 As shown, a method for anti-dialysis of the end surface of a paper liquid packaging material, which is to electrostatically spray the end surface of the paper packaging material 1 inside the lap joint of the paper 1 end surface with LDPE thermoplastic powder or food-grade thermosetting polyester The powder forms a powder coating, and then baked at a high temperature of 180°C, so that the powder material is melted and combined into a plastic layer 2, and is evenly and tightly bonded to the paper packaging material 1, covering the end surface of the paper packaging material 1, insulating the paper The contact between the section of the quality packaging material 1 and the outside world. figure 2 Shown is the structure of the seam of the above-mentioned paper liquid packaging material 1 after lapping is completed. It can be seen that the end surface of the paper packaging material 1 inside the seam is covered by the plastic layer 2, and the paper liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com