Lining wall concrete placement top-down method based on underground diaphragm wall

A technology for underground diaphragm walls and lining walls, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve problems such as water seepage, difficult air discharge, and formation of voids, etc., achieve simple operation process, improve construction efficiency, and speed up construction progress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

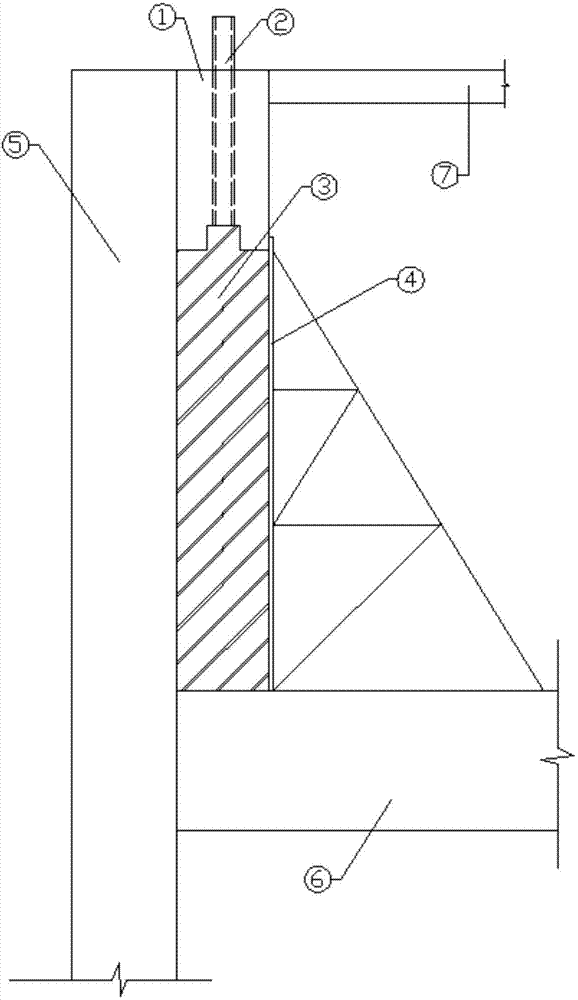

[0017] A method of pouring concrete for an inner lining wall based on an underground diaphragm wall, the pouring reverse method comprising the following steps:

[0018] (1) Complete the construction of the underground diaphragm wall 5;

[0019] (2) The construction of the foundation floor 6 is completed;

[0020] (3) The construction of the upper floor 7 is completed;

[0021] ⑷. Support the formwork of the upper lining wall, pour the upper lining wall concrete 1, and pre-embed a steel pipe 2 at intervals of 2-3 meters in the upper lining wall concrete, and set the lower end of each pre-embedded steel pipe on the The top of the inverted groove at the lower part of the upper lining wall has been poured; the pre-embedded steel pipes include ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com