Design method for grouting channel of prefabricated concrete vertical members

A technology of prefabricated concrete and vertical components, which is applied in the direction of building components, structural elements, building reinforcements, etc., can solve the problems of grouting materials not dense, not filling, leaking, etc., to meet quality requirements, construction operation is simple, ensure dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

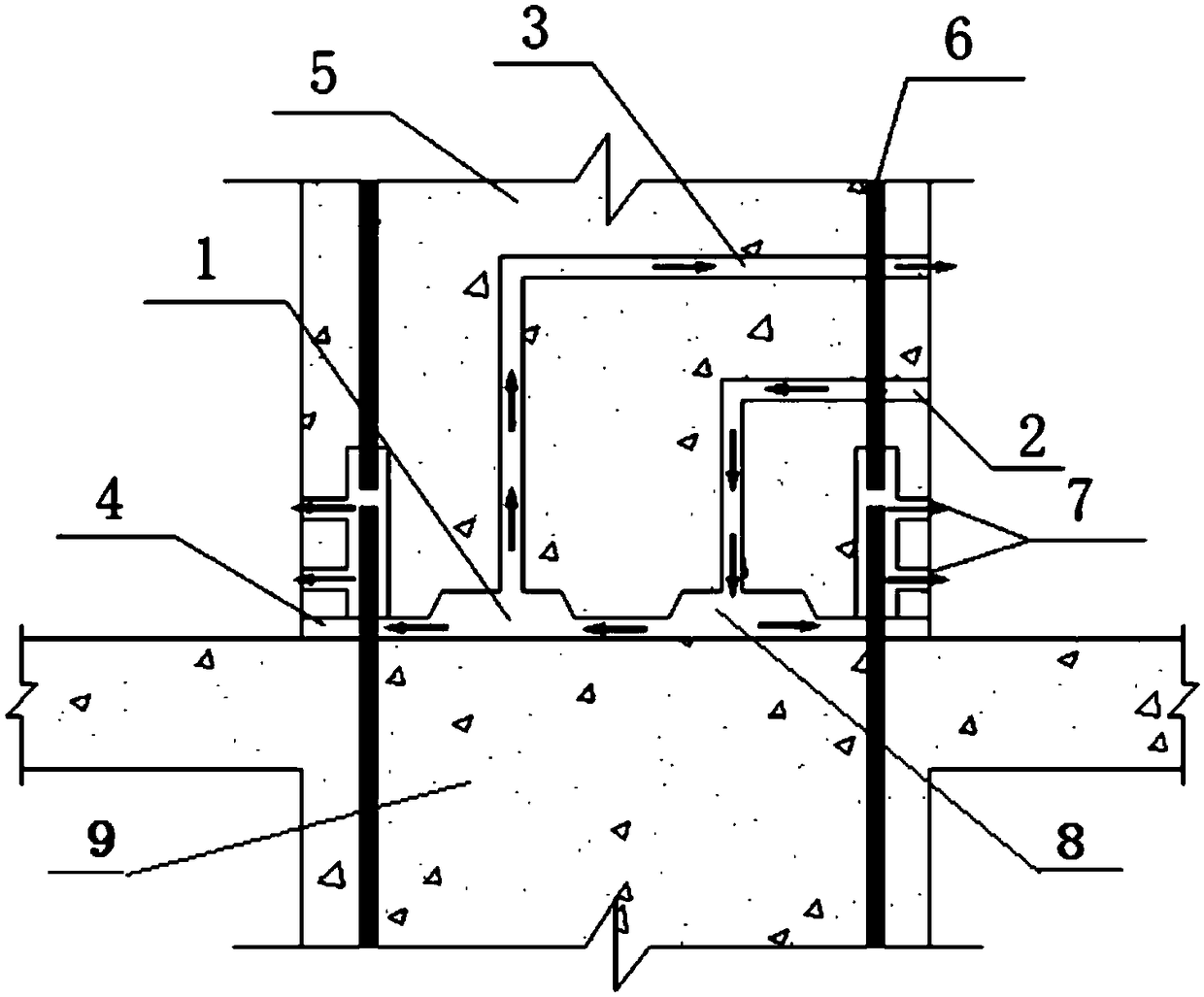

[0021] Embodiment 1: A method for designing the grouting channel of a prefabricated concrete vertical component, the structure of the grouting channel is as follows figure 1 shown, including the following steps:

[0022] (1) Prefabricate the upper precast concrete vertical member 5 and the lower precast concrete vertical member 9, connect the upper precast concrete vertical member 5 and the lower precast concrete vertical member 9 through the prefabricated vertical reinforcement 6, and the prefabricated vertical reinforcement 6 includes upper steel bars and lower steel bars, the upper steel bars are arranged around the upper precast concrete vertical member 5, the lower steel bars are arranged around the lower precast concrete vertical member 9, the upper precast concrete vertical member 5 and the lower precast concrete vertical member The junction of 9 has the horizontal joint 4 of upper and lower prefabricated components.

[0023] The first bottom keyway 1 and the second bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com