Construction method for integrated unilateral formwork of circular lining wall based on inverse method

A construction method and technology for lining walls, which are applied in basic structure engineering, artificial islands, sheet pile walls, etc., can solve the problems of planting bars, welding costs, increasing material and labor costs, and increasing the tension force of formwork, etc. Reduce material and labor costs, ensure strength, and reduce the effect of tie reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

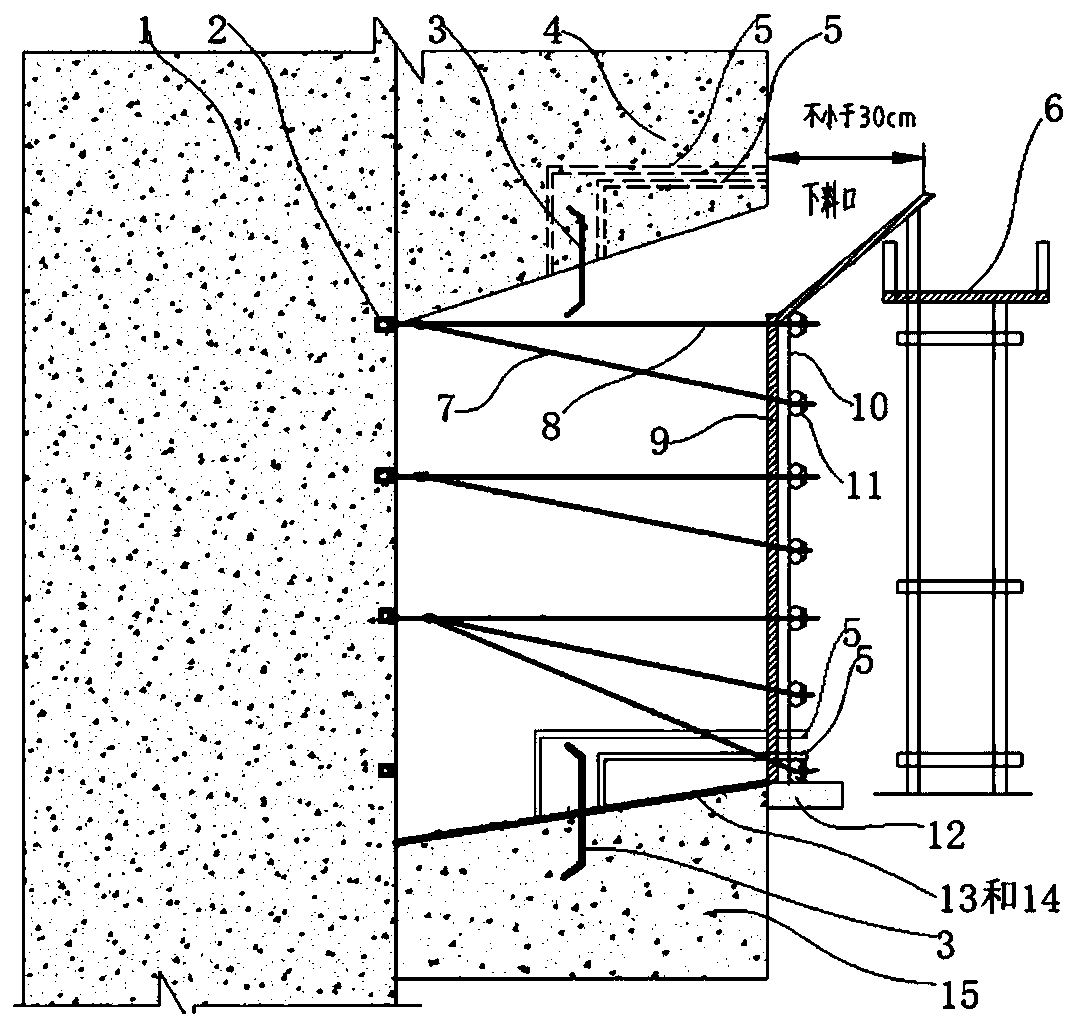

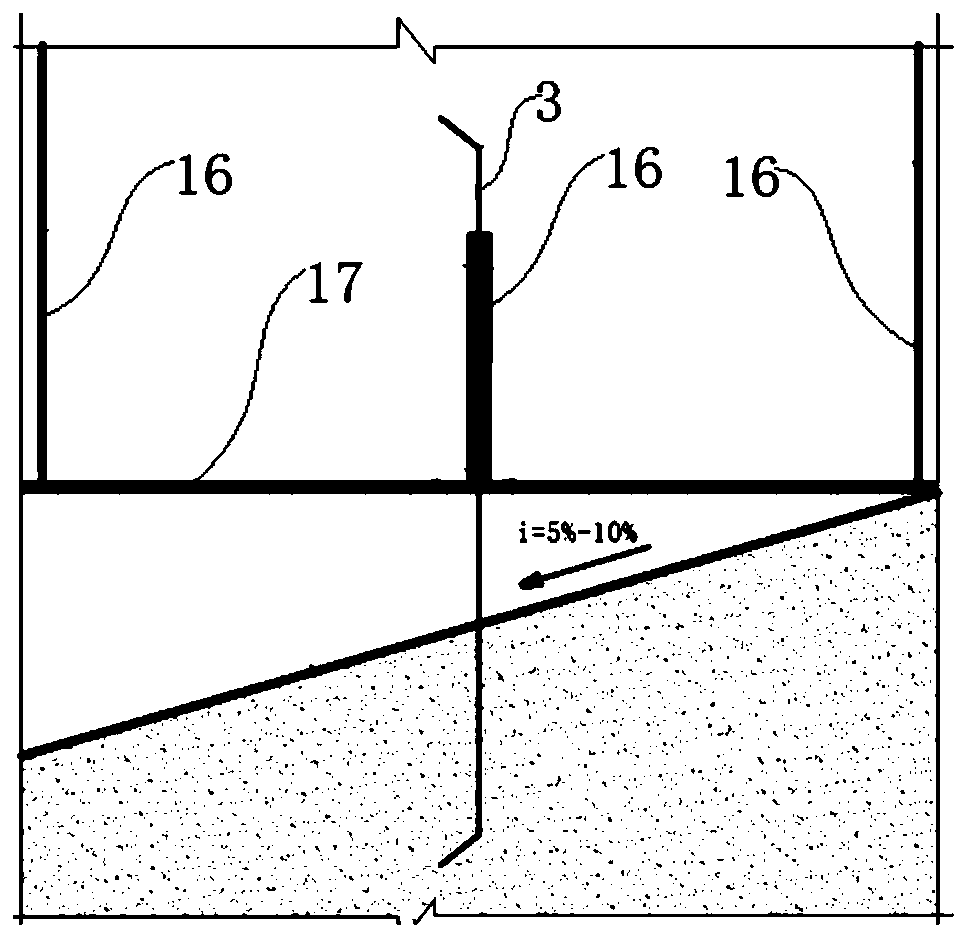

[0028] Such as figure 1 As shown, a construction method based on the inverse method for the overall unilateral formwork of the annular lining wall, including steps:

[0029] S1. When constructing the underground diaphragm wall 1, install the connector 2 on the steel skeleton of the underground diaphragm wall 1 according to the mold matching position of the layered construction of the lining wall, and expose the connector 2 to the underground continuous wall after excavating each layer of earthwork. Wall 1 surface and cleaning; Leveling and setting concrete cushion 12 (in the present embodiment, be the C20 concrete cushion 12 of wide 30cm, thick 15cm) after leveling formwork 9 bottom earthworks, guarantee formwork 9 (considering general pump house structure Structural steel bars need to be reserved on the lining wall. In the present embodiment, the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com